Section 2 | |||

|

|

|

|

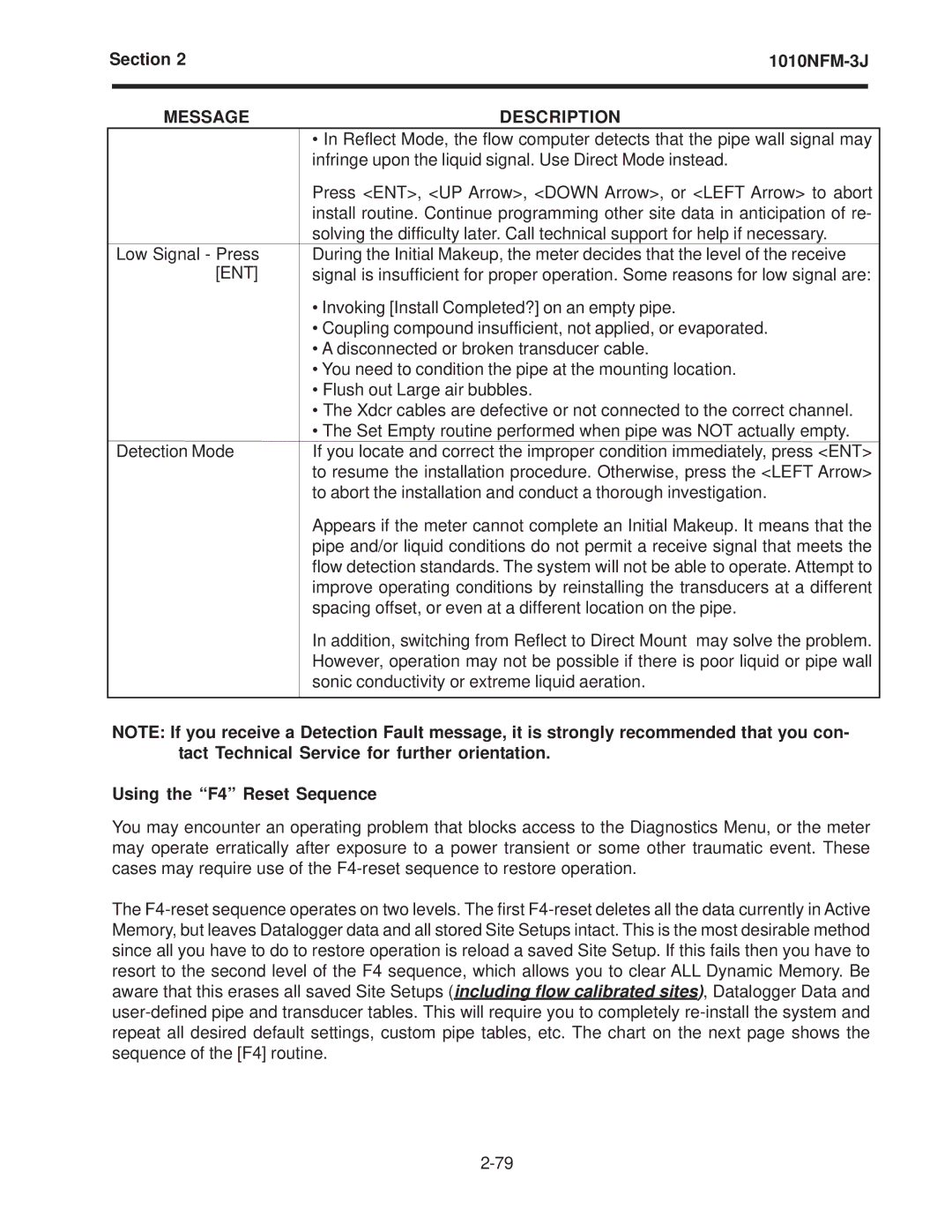

| MESSAGE | DESCRIPTION | |

|

| • In Reflect Mode, the flow computer detects that the pipe wall signal may | |

|

| infringe upon the liquid signal. Use Direct Mode instead. | |

|

| Press <ENT>, <UP Arrow>, <DOWN Arrow>, or <LEFT Arrow> to abort | |

|

| install routine. Continue programming other site data in anticipation of re- | |

|

| solving the difficulty later. Call technical support for help if necessary. | |

| Low Signal - Press | During the Initial Makeup, the meter decides that the level of the receive | |

| [ENT] | signal is insufficient for proper operation. Some reasons for low signal are: | |

|

| • Invoking [Install Completed?] on an empty pipe. | |

|

| • Coupling compound insufficient, not applied, or evaporated. | |

|

| • A disconnected or broken transducer cable. | |

|

| • You need to condition the pipe at the mounting location. | |

|

| • Flush out Large air bubbles. | |

|

| • The Xdcr cables are defective or not connected to the correct channel. | |

|

| • The Set Empty routine performed when pipe was NOT actually empty. | |

| Detection Mode | If you locate and correct the improper condition immediately, press <ENT> | |

|

| to resume the installation procedure. Otherwise, press the <LEFT Arrow> | |

|

| to abort the installation and conduct a thorough investigation. | |

|

| Appears if the meter cannot complete an Initial Makeup. It means that the | |

|

| pipe and/or liquid conditions do not permit a receive signal that meets the | |

|

| flow detection standards. The system will not be able to operate. Attempt to | |

|

| improve operating conditions by reinstalling the transducers at a different | |

|

| spacing offset, or even at a different location on the pipe. | |

|

| In addition, switching from Reflect to Direct Mount may solve the problem. | |

|

| However, operation may not be possible if there is poor liquid or pipe wall | |

|

| sonic conductivity or extreme liquid aeration. | |

|

|

|

|

NOTE: If you receive a Detection Fault message, it is strongly recommended that you con- tact Technical Service for further orientation.

Using the “F4” Reset Sequence

You may encounter an operating problem that blocks access to the Diagnostics Menu, or the meter may operate erratically after exposure to a power transient or some other traumatic event. These cases may require use of the

The