Section 3 | |

|

|

10.Connect the transducer cable, ensuring that you have observed the Upstream/Downstream orien- tation in respect to the cable and the input jack on the flow computer. If this is a

3.2MOUNTING TEMPERATURE SENSORS

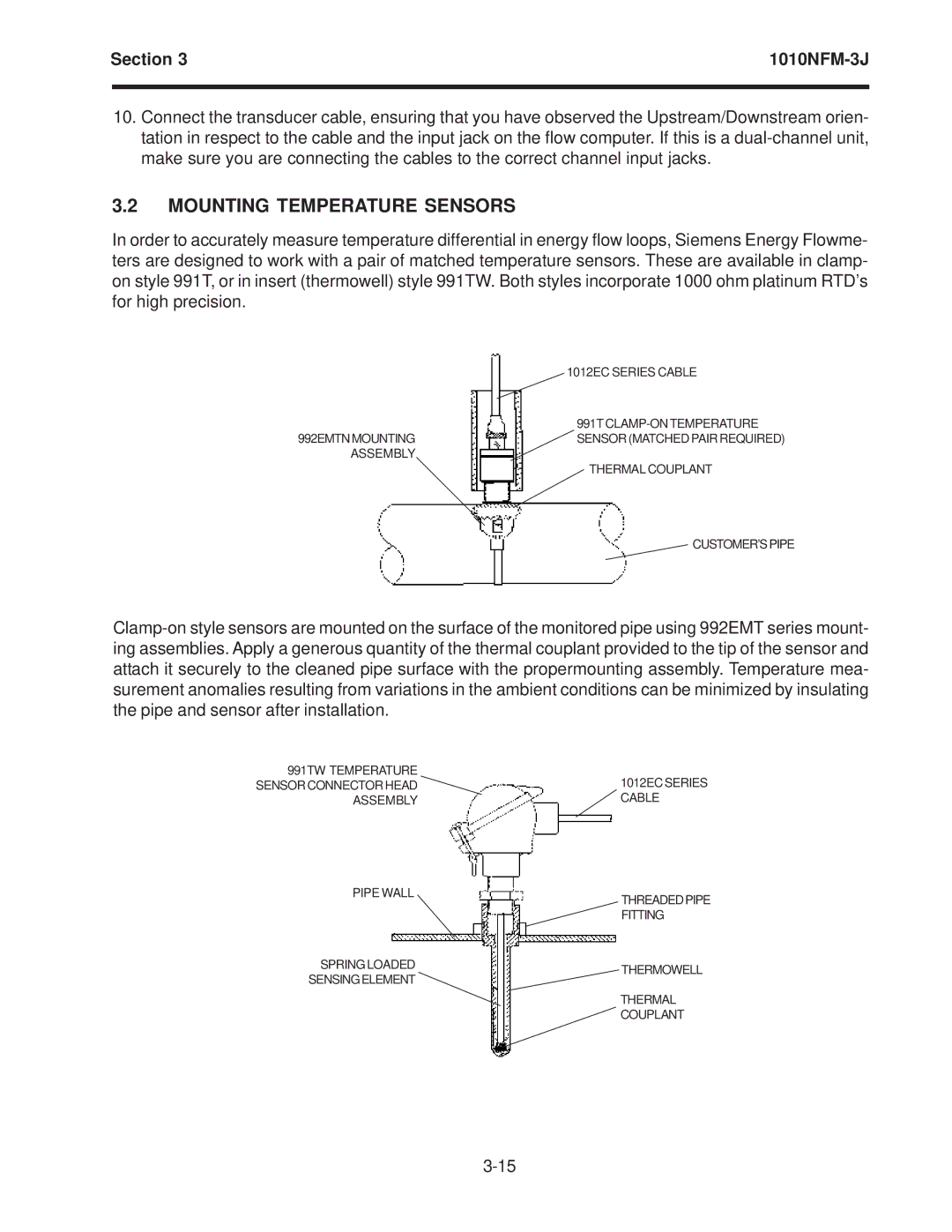

In order to accurately measure temperature differential in energy flow loops, Siemens Energy Flowme- ters are designed to work with a pair of matched temperature sensors. These are available in clamp- on style 991T, or in insert (thermowell) style 991TW. Both styles incorporate 1000 ohm platinum RTD’s for high precision.

1012EC SERIES CABLE

991T

992EMTN MOUNTINGSENSOR (MATCHED PAIR REQUIRED) ASSEMBLY

THERMAL COUPLANT

CUSTOMER’SPIPE

991TW TEMPERATURE | 1012EC SERIES |

SENSOR CONNECTOR HEAD | |

ASSEMBLY | CABLE |

PIPE WALL | THREADEDPIPE | |

| ||

| FITTING | |

SPRING LOADED | THERMOWELL | |

SENSINGELEMENT | ||

| ||

| THERMAL | |

| COUPLANT |