Section 2 | ||

|

|

|

2.11.10 USING THE 996PSP PIPE SIMULATOR

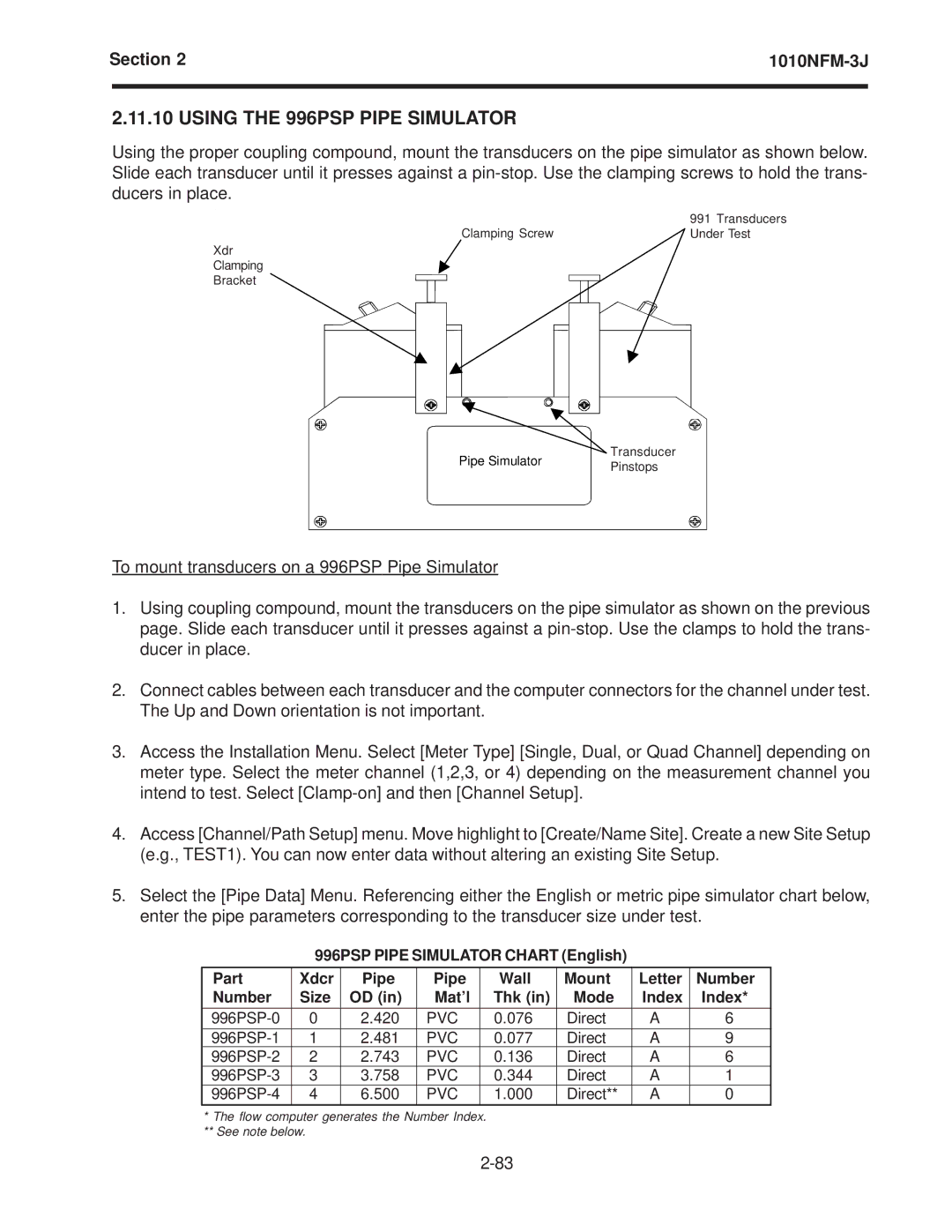

Using the proper coupling compound, mount the transducers on the pipe simulator as shown below. Slide each transducer until it presses against a

99191TransducersTra ucers

Clamping ScrewUnderTestt t

Under

Xdrdcr

Clampingl i

BracketBr t

Pipe Simulator

TransducerTran er PinstopsPinst

To mount transducers on a 996PSP Pipe Simulator

1.Using coupling compound, mount the transducers on the pipe simulator as shown on the previous page. Slide each transducer until it presses against a

2.Connect cables between each transducer and the computer connectors for the channel under test. The Up and Down orientation is not important.

3.Access the Installation Menu. Select [Meter Type] [Single, Dual, or Quad Channel] depending on meter type. Select the meter channel (1,2,3, or 4) depending on the measurement channel you intend to test. Select

4.Access [Channel/Path Setup] menu. Move highlight to [Create/Name Site]. Create a new Site Setup (e.g., TEST1). You can now enter data without altering an existing Site Setup.

5.Select the [Pipe Data] Menu. Referencing either the English or metric pipe simulator chart below, enter the pipe parameters corresponding to the transducer size under test.

996PSP PIPE SIMULATOR CHART (English)

Part | Xdcr | Pipe | Pipe | Wall | Mount | Letter | Number |

Number | Size | OD (in) | Mat’l | Thk (in) | Mode | Index | Index* |

0 | 2.420 | PVC | 0.076 | Direct | A | 6 | |

1 | 2.481 | PVC | 0.077 | Direct | A | 9 | |

2 | 2.743 | PVC | 0.136 | Direct | A | 6 | |

3 | 3.758 | PVC | 0.344 | Direct | A | 1 | |

4 | 6.500 | PVC | 1.000 | Direct** | A | 0 |

*The flow computer generates the Number Index.

**See note below.