Section 3 |

2.On a flat surface, attach the spacer bar to a mounting frame so that the reference hole on the spacer bar fits over the post on the platform of the frame; tighten the securing screw. Slide the second mounting frame onto the other end of the spacer bar, align the number index hole with the post on the platform; then tighten the securing screw. Ensure that the angled sides of both frames face away from each other. At the mounting location, place the mounting frame/spacer bar assem- bly on the pipe so that it rests on the top of the pipe. Wrap a mounting strap around the pipe. Engage the end of the mounting strap with the mounting strap adjusting screw. Slide it under the spring clip (if so equipped) of one of the mounting frames. Make sure to position it for easy access to the mounting strap adjusting screw. Do the same to the other mounting frame.

3.Tighten the mounting strap screw enough to take up all of the slack, but not enough to prevent rotation of the assembly. Rotate the assembly on the pipe to the 9 o’clock position ensuring that it is a smooth area without any raised spots or seams. Mark a generous area around the mounting frames (1/2” on either side and half again the length front and back) with a pencil or chalk. Move or revolve the assembly away from the area marked (loosen straps if necessary to do this).

4.Prepare the two areas you marked by

5.Reposition the assembly over the center of the prepared surfaces. Tighten the mounting straps to seat the assembly firmly on the pipe. Do not overtighten.

Apply a continuous

6.Observing the upstream to downstream orientation, attach the UP and DN cables to the transduc- ers. Attach the other ends to the flowmeter’s UP and DN terminals. See Engineering Drawing

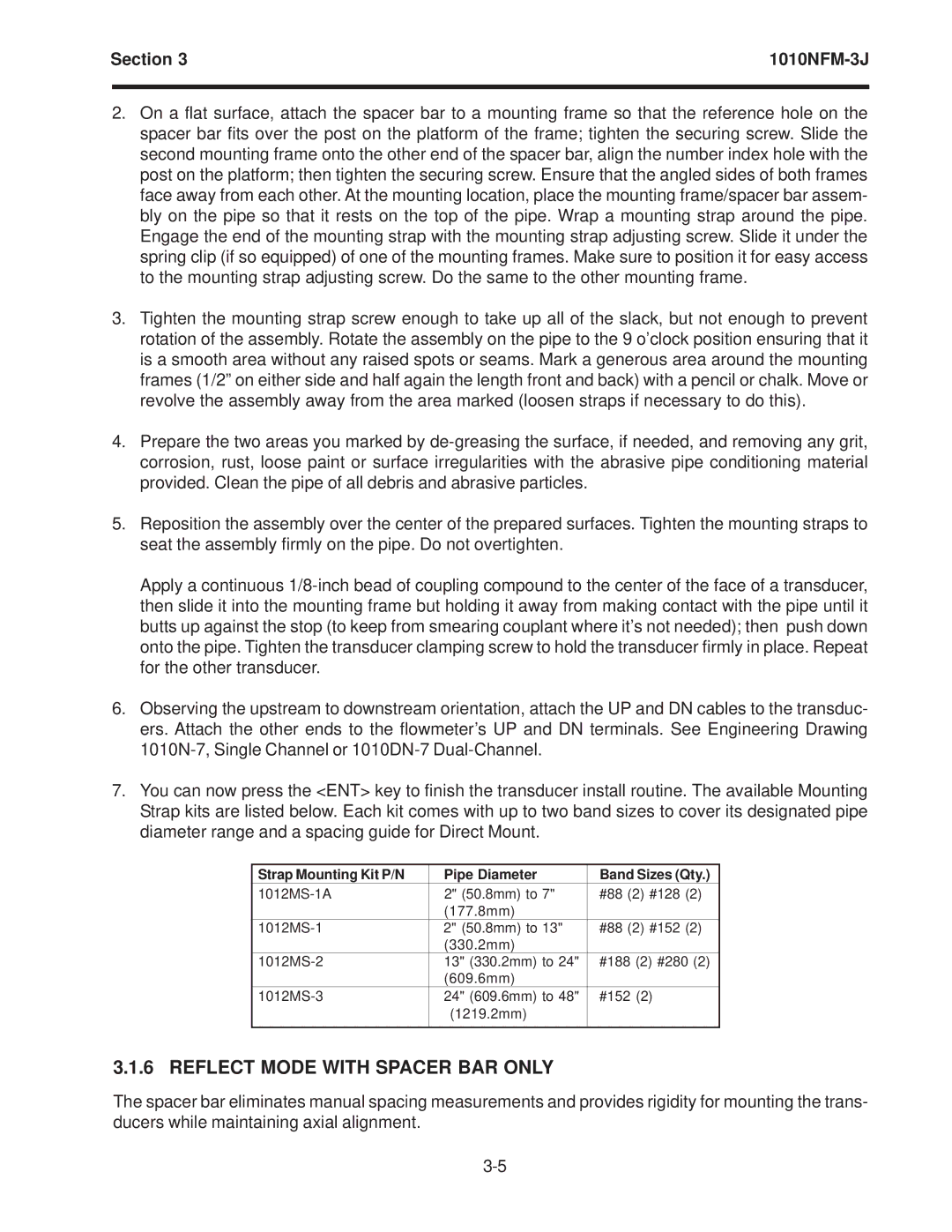

7.You can now press the <ENT> key to finish the transducer install routine. The available Mounting Strap kits are listed below. Each kit comes with up to two band sizes to cover its designated pipe diameter range and a spacing guide for Direct Mount.

Strap Mounting Kit P/N | Pipe Diameter | Band Sizes (Qty.) |

2" (50.8mm) to 7" | #88 (2) #128 (2) | |

| (177.8mm) |

|

2" (50.8mm) to 13" | #88 (2) #152 (2) | |

| (330.2mm) |

|

13" (330.2mm) to 24" | #188 (2) #280 (2) | |

| (609.6mm) |

|

24" (609.6mm) to 48" | #152 (2) | |

| (1219.2mm) |

|

|

|

|

3.1.6 REFLECT MODE WITH SPACER BAR ONLY

The spacer bar eliminates manual spacing measurements and provides rigidity for mounting the trans- ducers while maintaining axial alignment.