Section 3 |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

1011 Series |

|

|

|

|

|

| Spring Clip | |

1011 Series |

|

|

|

|

|

| ||

Transducer |

|

|

|

|

|

| Spring Clip | |

|

|

|

| Spacer |

| |||

Transducer |

|

|

|

| Bar |

| ||

|

|

|

|

|

| Spacer |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Spacerpacer BarBar |

Spacer Bar | Numberber IndexIndex |

Spacer Bar Reference | Securingecuring ScrewScrew |

Reference | |

Index Securing Screw |

|

Index Securing |

|

Screw |

|

| unting |

| Mounting |

StraStrapp

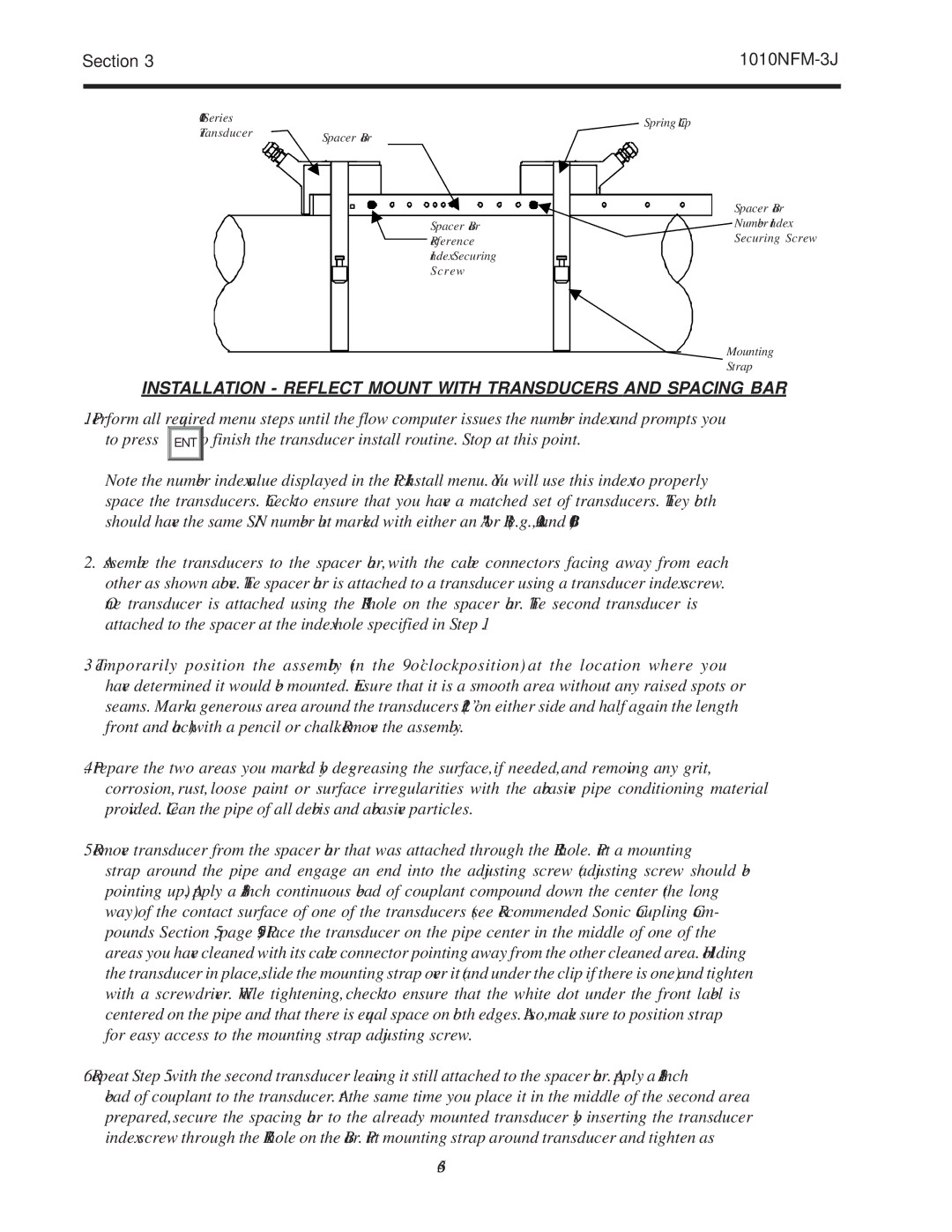

INSTALLATION - REFLECT MOUNT WITH TRANSDUCERS AND SPACING BAR

1.Perform all required menu steps until the flow computer issues the number index and prompts you to press ENT to finish the transducer install routine. Stop at this point.

Note the number index value displayed in the Pick/Install menu. You will use this index to properly space the transducers. Check to ensure that you have a matched set of transducers. They both should have the same S/N number but marked with either an “A” or “B” (e.g., 100A and 100B).

2.Assemble the transducers to the spacer bar, with the cable connectors facing away from each other as shown above. The spacer bar is attached to a transducer using a transducer index screw. One transducer is attached using the “REF” hole on the spacer bar. The second transducer is attached to the spacer at the index hole specified in Step 1.

3.Temporarily position the assembly (in the 9 o’clock position) at the location where you have determined it would be mounted. Ensure that it is a smooth area without any raised spots or seams. Mark a generous area around the transducers (1/2” on either side and half again the length front and back) with a pencil or chalk. Remove the assembly.

4.Prepare the two areas you marked by

5.Remove transducer from the spacer bar that was attached through the REF hole. Put a mounting strap around the pipe and engage an end into the adjusting screw (adjusting screw should be pointing up). Apply a

6.Repeat Step 5 with the second transducer leaving it still attached to the spacer bar. Apply a