Section 2 | ||

|

|

|

4.Access the Installation Menu. Select [Meter Type] [Single, Dual or Quad Channel] depending on meter type. Select the meter channel (1,2,3, or 4) depending on which measurement channel you intend to test. Select

5.Access the [Channel/Path Setup] menu. Move the highlight to [Create/Name Site]. Create a new Site Setup (e.g., TEST1). You can now enter data without altering an existing Site Setup.

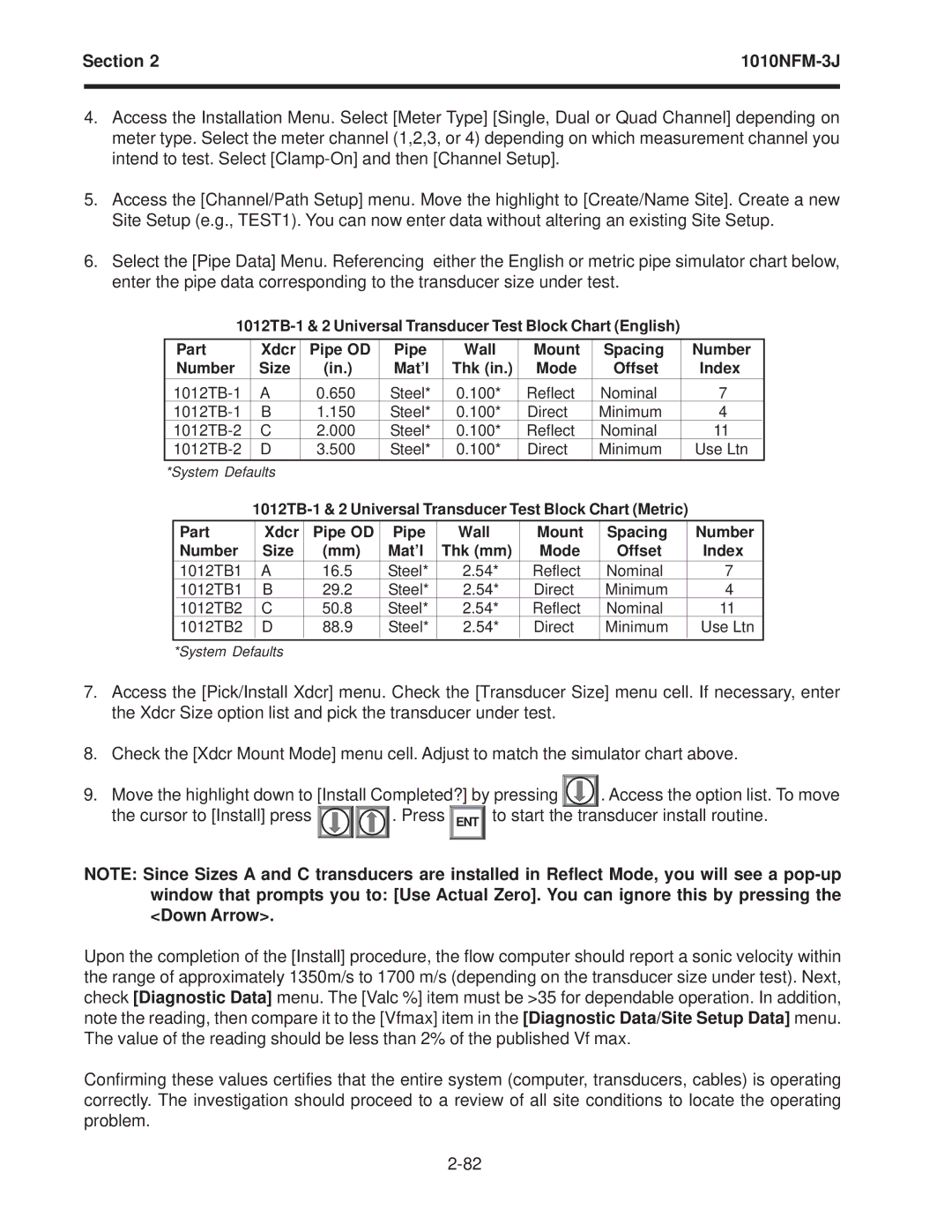

6.Select the [Pipe Data] Menu. Referencing either the English or metric pipe simulator chart below, enter the pipe data corresponding to the transducer size under test.

Part | Xdcr | Pipe OD | Pipe | Wall | Mount | Spacing | Number | |

Number | Size | (in.) | Mat’l | Thk (in.) | Mode | Offset | Index | |

A | 0.650 | Steel* | 0.100* | Reflect | Nominal | 7 |

| |

B | 1.150 | Steel* | 0.100* | Direct | Minimum | 4 |

| |

C | 2.000 | Steel* | 0.100* | Reflect | Nominal | 11 |

| |

D | 3.500 | Steel* | 0.100* | Direct | Minimum | Use Ltn |

| |

*System Defaults

| Part | Xdcr | Pipe OD | Pipe | Wall | Mount | Spacing | Number | |

| Number | Size | (mm) | Mat’l | Thk (mm) | Mode | Offset | Index | |

| 1012TB1 | A | 16.5 | Steel* | 2.54* | Reflect | Nominal | 7 |

|

| 1012TB1 | B | 29.2 | Steel* | 2.54* | Direct | Minimum | 4 |

|

| 1012TB2 | C | 50.8 | Steel* | 2.54* | Reflect | Nominal | 11 |

|

| 1012TB2 | D | 88.9 | Steel* | 2.54* | Direct | Minimum | Use Ltn |

|

*System Defaults

7.Access the [Pick/Install Xdcr] menu. Check the [Transducer Size] menu cell. If necessary, enter the Xdcr Size option list and pick the transducer under test.

8.Check the [Xdcr Mount Mode] menu cell. Adjust to match the simulator chart above.

9.Move the highlight down to [Install Completed?] by pressing ![]() . Access the option list. To move

. Access the option list. To move

the cursor to [Install] press ![]()

![]() . Press

. Press![]() ENT

ENT![]() to start the transducer install routine.

to start the transducer install routine.

NOTE: Since Sizes A and C transducers are installed in Reflect Mode, you will see a

Upon the completion of the [Install] procedure, the flow computer should report a sonic velocity within the range of approximately 1350m/s to 1700 m/s (depending on the transducer size under test). Next, check [Diagnostic Data] menu. The [Valc %] item must be >35 for dependable operation. In addition, note the reading, then compare it to the [Vfmax] item in the [Diagnostic Data/Site Setup Data] menu. The value of the reading should be less than 2% of the published Vf max.

Confirming these values certifies that the entire system (computer, transducers, cables) is operating correctly. The investigation should proceed to a review of all site conditions to locate the operating problem.