Section 2 | ||

|

|

|

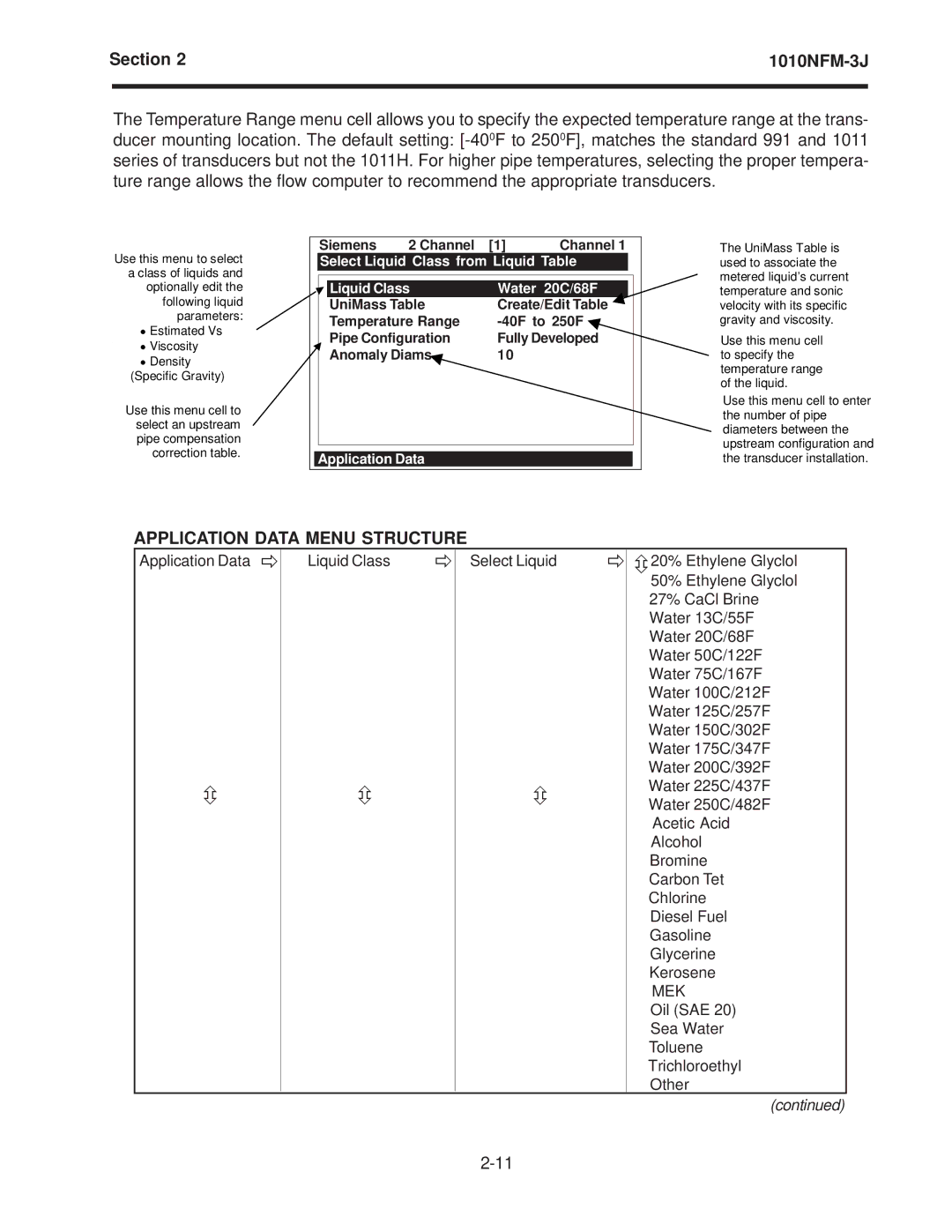

The Temperature Range menu cell allows you to specify the expected temperature range at the trans- ducer mounting location. The default setting:

Use this menu to select a class of liquids and optionally edit the following liquid parameters:

•Estimated Vs

•Viscosity

•Density (Specific Gravity)

Use this menu cell to select an upstream pipe compensation correction table.

| Siemens | 2 Channel | [1] | Channel 1 | |||

| Select Liquid Class from Liquid Table |

|

| ||||

|

|

|

|

|

| ||

|

| Liquid Class | Water 20C/68F |

|

| ||

|

| UniMass Table | Create/Edit Table |

|

| ||

|

| Temperature Range |

| ||||

|

| Pipe Configuration | Fully Developed |

| |||

|

| Anomaly Diams | 10 |

|

|

| |

|

|

|

|

|

|

|

|

Application Data

The UniMass Table is used to associate the metered liquid’s current temperature and sonic velocity with its specific gravity and viscosity.

Use this menu cell to specify the temperature range of the liquid.

Use this menu cell to enter the number of pipe diameters between the upstream configuration and the transducer installation.

APPLICATION DATA MENU STRUCTURE

Application Data

Liquid Class

Select Liquid

20% Ethylene Glyclol

50% Ethylene Glyclol

27% CaCl Brine

Water 13C/55F

Water 20C/68F

Water 50C/122F

Water 75C/167F

Water 100C/212F

Water 125C/257F

Water 150C/302F

Water 175C/347F

Water 200C/392F

Water 225C/437F

Water 250C/482F

Acetic Acid

Alcohol

Bromine

Carbon Tet

Chlorine

Diesel Fuel

Gasoline

Glycerine

Kerosene

MEK

Oil (SAE 20)

Sea Water

Toluene

Trichloroethyl

Other

(continued)