Monitoring and protective functions | 8 |

8.1Power unit protection, general

Description

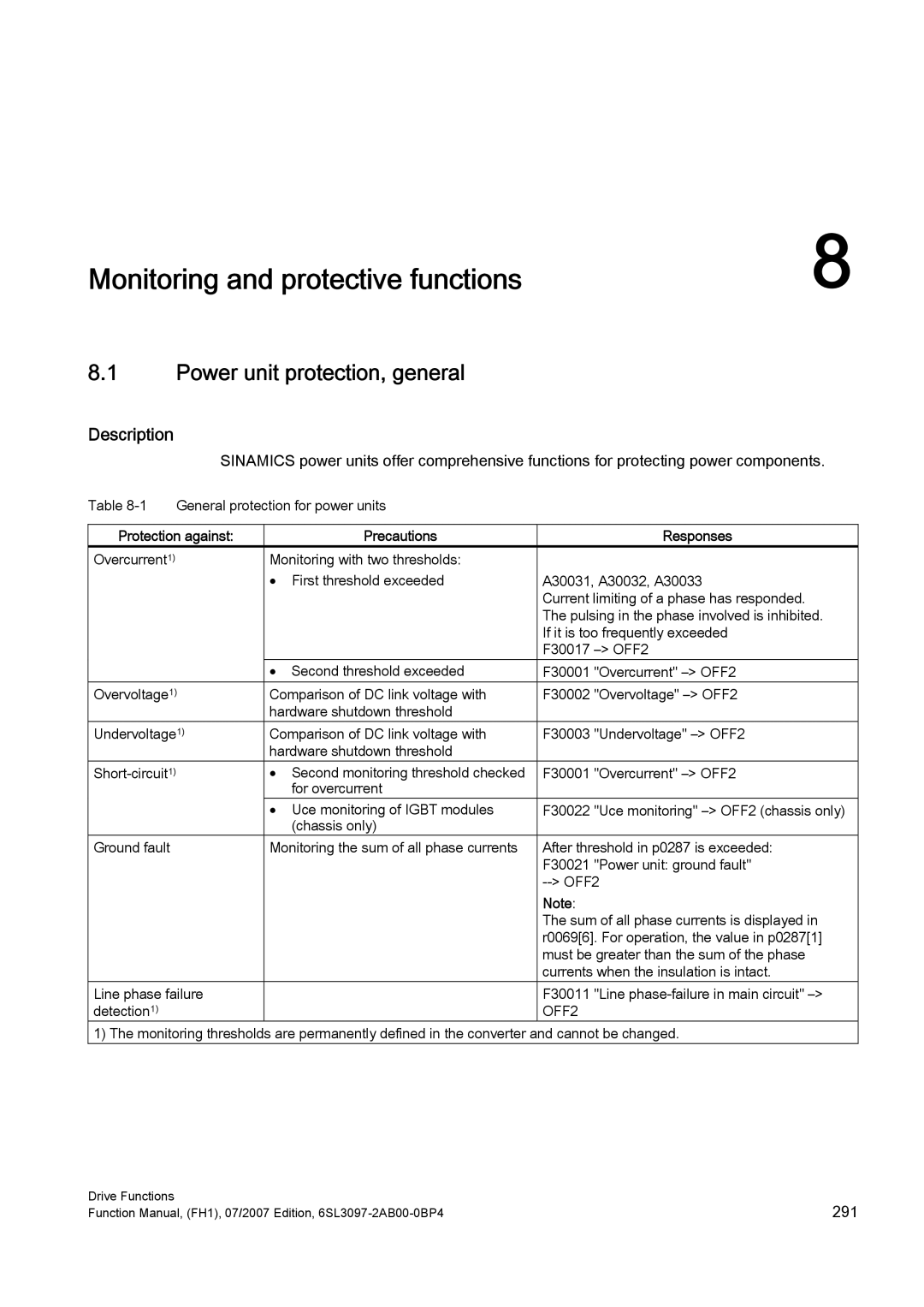

SINAMICS power units offer comprehensive functions for protecting power components.

Table | General protection for power units |

|

| ||

|

|

|

|

| |

Protection against: |

| Precautions |

| Responses | |

Overcurrent1) |

| Monitoring with two thresholds: |

|

| |

|

| • | First threshold exceeded | A30031, A30032, A30033 | |

|

|

|

| Current limiting of a phase has responded. | |

|

|

|

| The pulsing in the phase involved is inhibited. | |

|

|

|

| If it is too frequently exceeded | |

|

|

|

| F30017 | |

|

| • | Second threshold exceeded | F30001 | "Overcurrent" |

Overvoltage1) | Comparison of DC link voltage with | F30002 | "Overvoltage" | ||

|

| hardware shutdown threshold |

|

| |

Undervoltage1) | Comparison of DC link voltage with | F30003 | "Undervoltage" | ||

|

| hardware shutdown threshold |

|

| |

| • Second monitoring threshold checked | F30001 | "Overcurrent" | ||

|

|

| for overcurrent |

|

|

|

| • Uce monitoring of IGBT modules | F30022 | "Uce monitoring" | |

|

|

| (chassis only) |

|

|

Ground fault |

| Monitoring the sum of all phase currents | After threshold in p0287 is exceeded: | ||

|

|

|

| F30021 | "Power unit: ground fault" |

|

|

|

| ||

|

|

|

| Note: |

|

|

|

|

| The sum of all phase currents is displayed in | |

|

|

|

| r0069[6]. For operation, the value in p0287[1] | |

|

|

|

| must be greater than the sum of the phase | |

|

|

|

| currents when the insulation is intact. | |

Line phase failure |

|

| F30011 | "Line | |

detection1) |

|

|

| OFF2 |

|

1) The monitoring thresholds are permanently defined in the converter and cannot be changed.

Drive Functions | 291 |

Function Manual, (FH1), 07/2007 Edition, |