Safety Integrated basic functions 9.1 General information

Switch-off signal paths

Two independent

If a fault is discovered in the

Monitoring cycle

The

The safety monitoring clock cycle lasts a minimum of 4 ms. Increasing the basic DRIVE- CLiQ sampling time (p0110) also increases the safety monitoring clock cycle.

Crosswise data comparison

A cyclic

Parameter overview (see SINAMICS S List Manual)

●r9780 SI monitoring clock cycle (Control Unit)

●r9880 SI monitoring clock cycle (Motor Module)

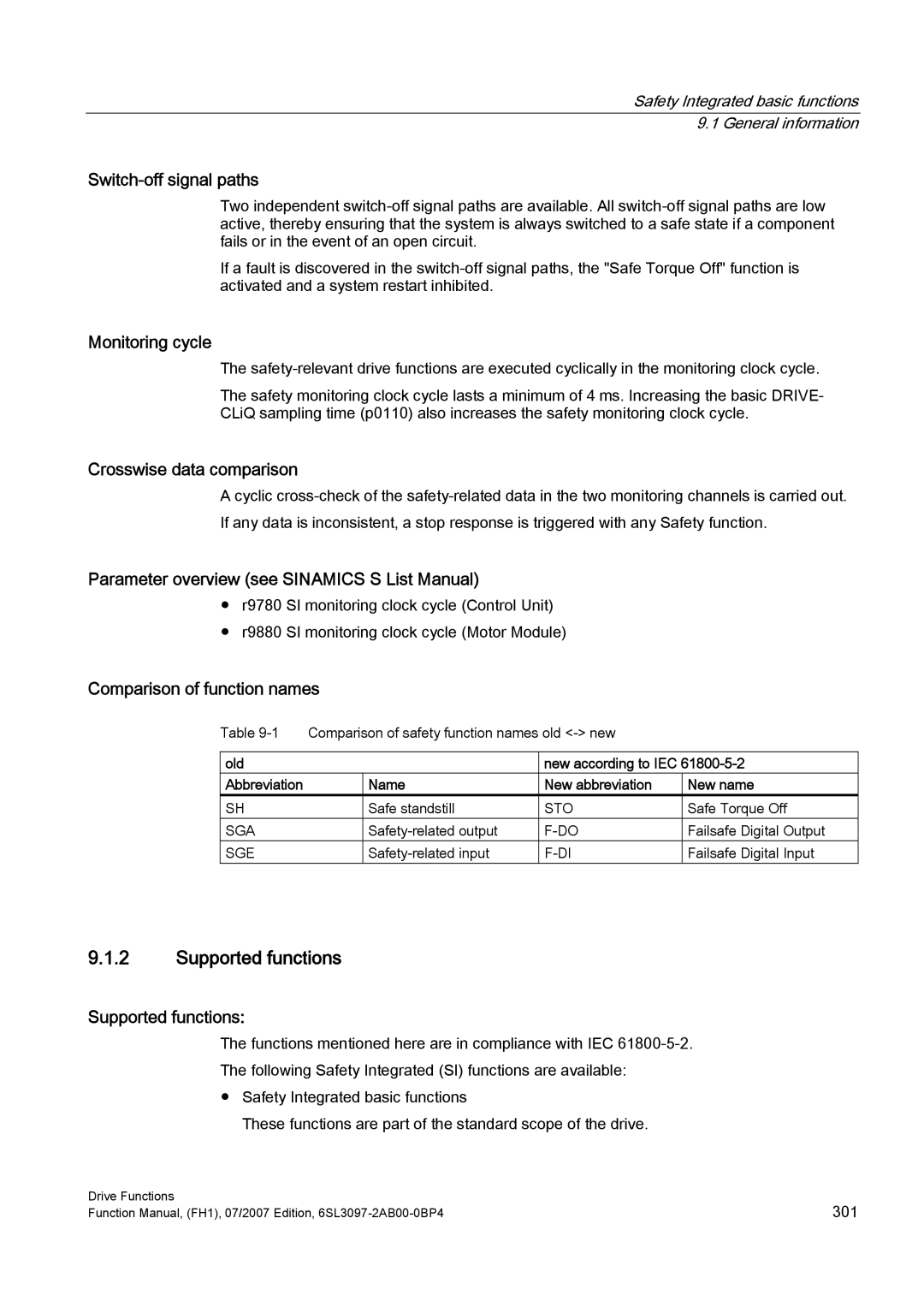

Comparison of function names

Table | Comparison of safety function names old |

| ||

|

|

|

|

|

old |

|

| new according to IEC | |

Abbreviation |

| Name | New abbreviation | New name |

SH |

| Safe standstill | STO | Safe Torque Off |

SGA |

| Failsafe Digital Output | ||

SGE |

| Failsafe Digital Input | ||

9.1.2Supported functions

Supported functions:

The functions mentioned here are in compliance with IEC

The following Safety Integrated (SI) functions are available:

●Safety Integrated basic functions

These functions are part of the standard scope of the drive.

Drive Functions | 301 |

Function Manual, (FH1), 07/2007 Edition, |