Communication PROFIBUS DP/PROFINET IO 10.2 Communication via PROFIBUS DP

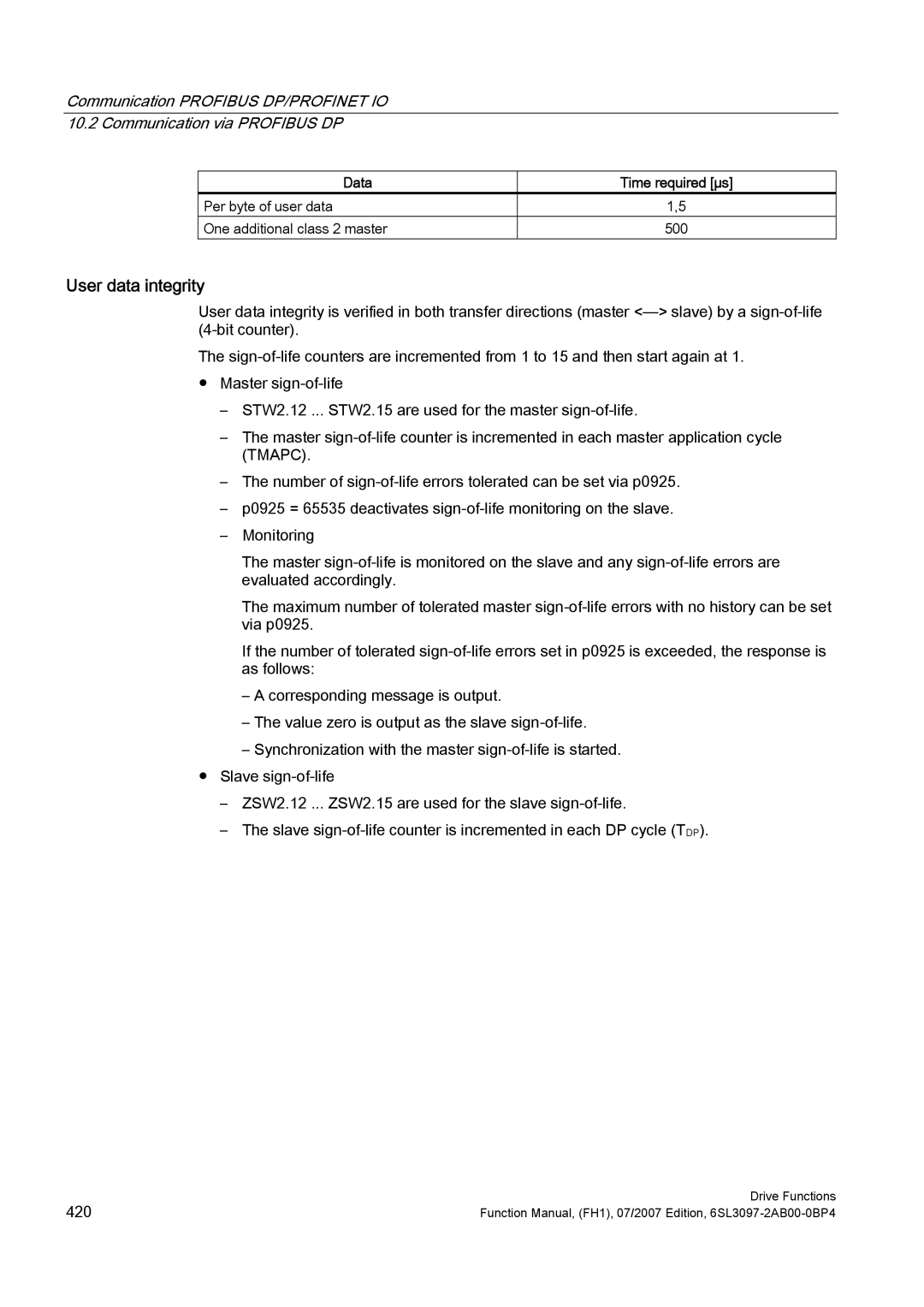

Data | Time required [µs] |

Per byte of user data | 1,5 |

One additional class 2 master | 500 |

User data integrity

User data integrity is verified in both transfer directions (master

The

●Master

–STW2.12 ... STW2.15 are used for the master

–The master

–The number of

–p0925 = 65535 deactivates

–Monitoring

The master

The maximum number of tolerated master

If the number of tolerated

–A corresponding message is output.

–The value zero is output as the slave

–Synchronization with the master

●Slave

–ZSW2.12 ... ZSW2.15 are used for the slave

–The slave

420 | Drive Functions |

Function Manual, (FH1), 07/2007 Edition, |