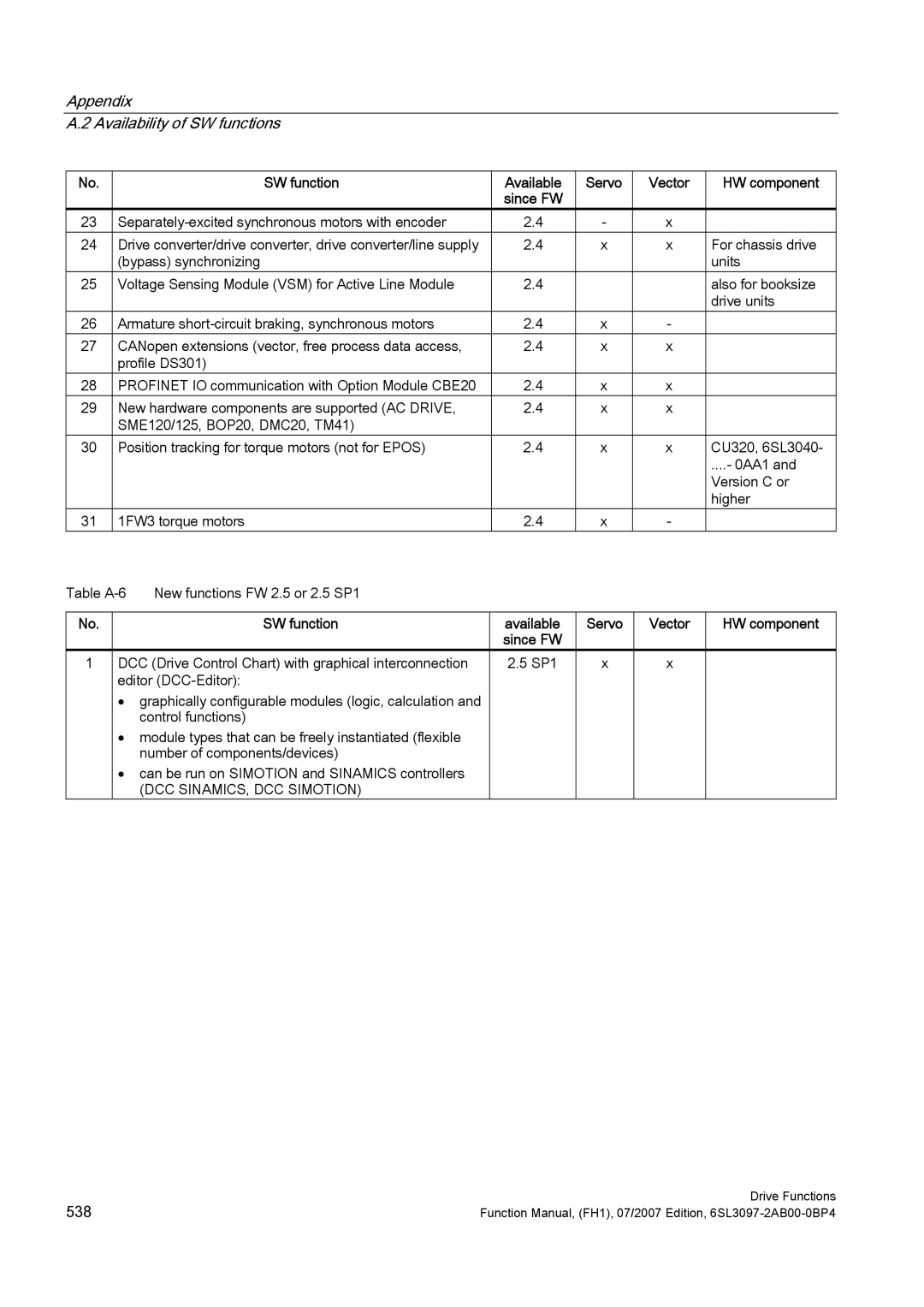

Appendix

A.2 Availability of SW functions

No. |

| SW function | Available | Servo | Vector | HW component |

|

|

| since FW |

|

|

|

23 | 2.4 | - | x |

| ||

24 | Drive converter/drive converter, drive converter/line supply | 2.4 | x | x | For chassis drive | |

| (bypass) synchronizing |

|

|

| units | |

25 | Voltage Sensing Module (VSM) for Active Line Module | 2.4 |

|

| also for booksize | |

|

|

|

|

|

| drive units |

26 | Armature | 2.4 | x | - |

| |

27 | CANopen extensions (vector, free process data access, | 2.4 | x | x |

| |

| profile DS301) |

|

|

|

| |

28 | PROFINET IO communication with Option Module CBE20 | 2.4 | x | x |

| |

29 | New hardware components are supported (AC DRIVE, | 2.4 | x | x |

| |

| SME120/125, BOP20, DMC20, TM41) |

|

|

|

| |

30 | Position tracking for torque motors (not for EPOS) | 2.4 | x | x | CU320, 6SL3040- | |

|

|

|

|

|

| ....- 0AA1 and |

|

|

|

|

|

| Version C or |

|

|

|

|

|

| higher |

31 | 1FW3 torque motors | 2.4 | x | - |

| |

Table | New functions FW 2.5 or 2.5 SP1 |

|

|

|

| |

No. | SW function |

1DCC (Drive Control Chart) with graphical interconnection editor

•graphically configurable modules (logic, calculation and control functions)

•module types that can be freely instantiated (flexible number of components/devices)

•can be run on SIMOTION and SINAMICS controllers

(DCC SINAMICS, DCC SIMOTION)

available since FW

2.5 SP1

Servo | Vector | HW component |

|

|

|

x | x |

|

|

|

|

538 | Drive Functions |

Function Manual, (FH1), 07/2007 Edition, |