Hyundai Robot Hi4

Page

Head Office JEONHA-DONG, DONG-GU

Contents

2.2

Basic things for step

Condition setting

Application condition

Setting the field bus

Machine

R17

Palletizing pattern register Pallete dip angle measurement

R10

R18

R137

R123

R136

R138

Menu tree

11.4.1

11.4.2

11.4.3

Contents

Panel, Teach pendant

Safety

General

Safety, Operation Panel, Teach Pendant 1 Safety

Invalid environments

Relevant Safety Standards

Safety Training

Safety Marking

Mandatory

Speed Limitation Function-ISO 10218EN 775

Safety Stop Function-ISO 10218EN 775

Operation Mode Selection- ANSI/RIA R15.06-1999

Working Envelope Restriction- ANSI/RIA R15.06-1999

Installation of Robot

Safety Fence

Safety, Operation Panel, Teach Pendant 1 Safety

Safety, Operation Panel, Teach Pendant 1 Safety

Robot installation

General Safety Precautions

Technical Safety Precautions

Safety, Operation Panel, Teach Pendant 1 Safety

Space for robot installation

Safety Working Procedures

Safety measure for robot operation

Safety, Operation Panel, Teach Pendant 1 Safety

Interlock

Safety Measure for Robot Try-out

Safety, Operation Panel, Teach Pendant 1 Safety

Safety Measures for Entering Inside the Safety Fence

Safety Measures for Maintenance and Repair

Position

Safety, Operation Panel, Teach Pendant 1 Safety

Necessary Actions after Completion of Maintenance and Repair

Safety Functions

Safety Control Chain of Operation

Safety Chain of Operation

Emergency Stop

Status of Emergency stop

Operating Speed

Safety Related to End Effectors

Gripper

Tools and Workpiece

Liabilities

Safety, Operation Panel, Teach Pendant 1 Safety

Motor on

Error

Operation Panel

Emergency Stop

Stop

AUTO/MANUAL

Please refer to the following table

Teach Pendant

External Shape of Teach Pendant

Weavon WEV#=1 Arcon ASF#=1

Screen of Teach Pendant

Move

Arcof AEF#=1 Weavof

Conti / JOG on

Coord

AUX Axis

ACC / Intp

ESC

Right position of Title Frame

Shiftfast

Speed

LCD

SETYes

Ch/Var/Fn/CMD

STOP/MANOUT

PROG/STEP

Basic operation

Power OFF/ Motor OFF

Basic operation

How to initiate the system

Teaching

Select the type of robot connected controller

Step and Function

PNo999* S/F1/0 Spd100.00

Parameter of Step command line

Basic things for step

Select PF menu

Interpolation locus from between Step and Step

Pose

= Robot coordinate system E = Encoder

Tool number

Speed

Accuracy

Output option

Stop condition

Stop state variable

143938 *** Step Pose Data *** A0 S4

When the coordinate system is set as encoder

Step position validation/modification method

Coordination Base,Robot,Encoder

When the coordinate system is set as Base or Robot

000

Select and Enter number. Press SET

Step

50.000

Coordinate system

JOG operation key

Xis C o o rd

Axis coordinate

B o t C o o rd

Robot coordinate

Axis direction Rotation direction

Rzu

User coordinate

Tool coordinate

It shows that the robot is operating without tool

Program No. = Step No. = Tool No. =

Auto tool setting

143938 ***AUTO Tool SETg*** A0 S4

Select and Enter number. Press SET Execute

Service Menu

Protect Storage media format Save/Load Sram Card

Service Menu

Use Number/UpDown and press SET Previous Next

11 DIO169

Monitoring

143938 *** Monitoring *** A0 S4 Monitor OFF

Equalizerless GUN data

Enter the number of line and press SET

Command Angle

Current Command Angle

PN100* S/F=4/0 Sp100.00

Service

143938 *** M a N U a L A0 S4

Mspr on

PN100* S/F=4/0 Sp100.00 RobotH120, 6axes

Break Slip Count Outline

Slip count reset

Slip Count display/setting Outline

Use Number/UpDown and press SET

Clear to slip count?

CP=

CR=

CS=

143938 *** M a N U a L

Servo GUN Data Outline

OFF

Palletize Register Outline

Work State

Counter

OFF

Register

Register

Shift buffer

Select and Enter number. Press SET

XYZ Shift Register

Register A0 S4

Complete

Service menu

Shift buffers

Reference Parallel movement shift

Work작업A물Awork작업물a a

On-line shift register Group

Register A0 S4 ON-line shift register

Service menu

Palletizing register

Register A0 S4 Palletizing register

# Palletizing preset

Pallet No

Start count

Input the palletize pallet number.1-16

Frequency condition register

Select and Enter number. Press SET End

Conveyor Data

Register

Select Enter Number. Press SET

Conveyor data clear. Continue? YES/NO

Works entered the CV line =

Variable

Index

Previous Next Index

Edit Program

Select the Program modify and then displays as follows

143938 *** Program modify *** A0 S4 Condition modify

Modify writing condition totally

MX2

Modify speed in record totally

143938** Speed Modification **A0 S4

Modify position in record totally

143938 ** Position modify ** A0 S4

T1= Deg R2=

Is shifted

T1= Deg

T1= Deg R1=

Step Copy

Step Copy

Service menu

Step Reverse-Copy

143938 * Reverse step copy * A0 S4

Service menu

Edit program in running Hot Edit

Not running state. Use Manual mode.ESC

HotE022/3/1 PB022/4/0

Apply

Service System

Apply hot edit, First ?

Applying initiated CALLing info Escape

143938 *** Hotedit *** A0 S4

SR100% HotE022/3/1* PB022/4/0 S1 Move P,S=30%,A=1,T=0

Hot eidt A0 S4

Delete

File Management

Copy

Protect

File display A0 S4

Internal memory file name

All files? Yes, or just programs? No

File, 31351 Block free

Program first data

PN100* S/F4/0

File, 63156 block free. Page 1

Internal program axis no

143938 *** Number of axes *** A0 S4 Internal memory

Previous Next Escape

Internal memory

Rename

Rename

143938 *** RenameRAM *** A0 S4 H120 .991 31 2001-07-09

143938 *** RenameRAM *** A0 S4 H120 .991 31 2001-07-09

143938 *** RenameRAM *** A0 S4 H120 *991 31 2001-07-09

Enter new No and press SET

File, 31351 Block free. Page 1

Use PF Key and select

143938 *** RenameRAM *** A0 S4

H120 *995 31 2001-07-09

Service menu

H120

Copy

Copy

Robot

Select Cancel Previous Next Excute

Delete

Delete

H120 991

H120 .991 Delete? YesAll=1/No

Protect

Protect

Protect or Release?1Protect/Release

Reference

Storage Media Format

143938 ** Sram Card Format ** A0 S4

Press executePF5 or ESC key

Next

Save/Load Sram Card

Load all files from the Sram card

143938* Save/load all files * A0 S4 DIR

Folder, 1999 KB free. Page 1

Enter the name if a folder to read.Any

143938* Save/load all files * A0 S4

Previous Next Select

Program Conversion

143938 *** Conversion

Mirror Image Off-Line XYZ shift

Coordinate transformation

Contents of window

Object program

Program Destination program

Mirror Image

Enbl

Enter number and press SET Execute

Service menu

Off-Line XYZ Shift

Example Parallel transfer of the workpiece

143938 * Off-Line XYZ Shift * A0 S4

Enter number and press SET

System Checking

Following is displayed in system checking menu

143938 *** System checking *** A0 S4

System version

143938 *** System version *** A0 S4

Press ESC or R

Run time

Run time

Press ESC or R

Run time

Clear YES / no

Data is cleared as selecting YES and following is displayed

=00 Total cycle count =0

Diagnosis of troubles

Check

Service menu

143938 *** Error Log no *** A0 S4

Error logging

143938 *** Error logging *** A0 S4 0005 25

Refresh?

YES/NO

Stop History

143938 *** Stop Logging *** A0 S4 01 25

Use UpDown Press SET

Service menu

Press PF3, PF4, ESC or R

Operation History

143938 ** Operation Hist ** A0 S4

Refresh? Previous Next

Date = Time =

Date setting Date, Time

143938 *** Date/Time set *** A0 S4

Select and Enter number, Press SET

Chap 4 Condition Setting

143938 *** Condition set *** A0 S4

Press SHIFT+-- Key AppliCnd End

Modification method

Step go/back max. speed

Service

Cycle type

Playback

Function in step go/back

Speed rate

Record speed type

Select PF menu Service System

Robot lock

N U a L

Crd01

Interpolation base

User Coordinate

=100%,A=0,T=1

→ 12. Coordinate setting → 1. User coordinate

Chapter Application condition

Conveyor Oper=Normal,Simulat.,Test Search range

Cond Set PF5, Press AppliCnd PF1 Screen display

143938* Application Condition A0 S4

Press SHIFT+-- Key Cond Set

Conveyor operation

T O

RobotH120, 6axes Steps

Search reference position record

Service Rel Wait

Search Range

Move P S=100% A=0 T=1

Spot welding

PN100* S/F4/0

RobotH120, 6 axes Steps

143938

Service Rel Wait Cond Set

Gun Search reference point record

G1 SW Wd-On

OutputDO signal clear

On-line Shift Register Clear

System setting

System setting

Spot welding datacondition,sequence Equalizing parameter

Palletizing pattern register Palette dip angle measurement

System setting

143938 *** System setting *** A0 S4 User parameter

Press SHIFT+-- Key

User configuration

143938 * User configuration * A0 S4

Next End

Display language

Pose Record Type

Change of cursor position in Auto mode

Service Rel.WAIT

Start type

Confirm when the command delete

DeleteYes/No? Service System

Wait DI/WI Forcible Release

Power failure Detection Not Changeable

Dettachment of Teach Pendant

External Program selection

Using the program strobe signal

Value of Prog Selec Sig input is Service System

Step SET Alarm Type

Lowest position proportion of the cursor

Using the collision sensor

Coordinate setting Use Number/UpDown and press SET

Controller Parameter

Input/Output signal selection

143938** DIO signal setting ** A0 S4 Input signal logic

DI9

Previous

143938*** do signal logic

DO9

143938 ** do Sig attribute ** A0 S4

DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 DO9

143938 *** Pulse table

Enter number. Press

143938 *** Delay table

MXUnfolding Sig = X1

143938 ** DI Sig assignment ** A0 S4

External reset

Monitoring

External start External stop

B05

BO1

BO3

B07

High do

Setting the Earlier output Outline

Sig Time

Sec Low GO High

„ Resister the name of in/output signal

DIO name

Press SET for string input

143938 ** Character input ** A0 S4

Use UpDown, and press SET Complete

File not exist, Create file? YES/NO Done

143938* En/Disable Fieldbus * A0 S4

SHIFT+-- to En/Disable

Done

DI1 DI8

DI9

DI9

143938 *** Assign Input No *** A0 S4

DI1

Previous Next Done

143938*** Assign Outpur No *** A0 S4

Form Previous

Teach Pendant Cntp Outline

Serial port

143938 * Serial port select* A0 S4 Teach Pendant Cntp

Cant modify! Private port for T/P.ESE Previous Next

143938 *** Serial to I/O *** A0 S4

External computer and visa versa

Interface with the external vision system

Auto

Robot Ready

Ready

Enter number and press SET Previous Next Complete

143938 *** Home position *** A0 S4

Home position registration

Actual screen

Home 1 Program No. = Step No. =

Return to the previous position

143938 ** Previous position ** A0 S4

Press SHIFT+

End Relay Output Time

Relay

Sec

Interlock error time

Interlock error timer = 60 sec

143938 *** Interlock Abn.*** A0 S4

External error output

143938 *** Error output *** A0 S4

Signal name Assignment and Quantity Type

System setting

Power Saving PWM OFF

12.8

Press SHIFT+-- Key

Shift Limit

200.0

Setting the user key

GUN2

143938 *** f-key setting *** A0 S4

F2= F3= 0 f4= 527

Select and Enter number. Press SET Previous Next Complete

143938 *Coordinate assignment* A0 S4 User coordinate

Procedure

Coordination system registration

Stationary tool coordinate

143938 *** User coordinate *** A0 S4

Staionary tool X1=

143938 *** Staionary tool *** A0 S4

Staionary tool

Staionary tool X2=

Machine Parameter

143938 ** Machine parameter ** A0 S4 Tool data

Tool Weight

Tool Data

Component

IzZf

Reference ⑴ Auto calibration Outline

143938 ***AUTO Tool SETg*** A0S4

HH : Body Torch

Adjust angle by jogging, then push PF5 Execute

143938 ***TOOL Angle SETg*** A0S4

==H Side

90.0

Axis Constant

143938 *** Axis constants *** A0 S4

Use UpDown Key and press SET

Soft Limit

143938 *** Software limit *** A0 S4

Use UpDown Key and press SET Previous Next

143938 ** ARM interference ** A0 S4

Arm Interference Angle

Outline It sets the working limit between the ARM

Min = 25.0 Max =

Encoder Offset Calibration

Outline It calibrates the original point of encoder

Encoder calibrationData input

R2= R1=

After axis Oper, press REC.ESCusable

143938 *** Encoder offset *** A0 S4

2000000000

Outline It sets acceleration/deceleration time

Contents of the screen „ Maximum speed

Acceleration/Deceleration Speed Parameter

117

Axis Dead Zone

143938 ** B axis dead zone ** A0 S4

Level

Level = 0 ∼

Accuracy

Distance

Cornering

Discontinuous step Continuous step

Speeds

Inertia 00Kgm2 Center

Contents of the screen

Additional load per each axis

Inertia

System setting

Application parameter

143938 *Application parameter* A0 S4 Spot & Stud

Arc Palletizing Conveyor Volt. output proportional to Speed

Spot & Stud

143938 *** Spot&Stud Weld *** A0 S4 Air-gun welding data

143938 *Air-gun welding data* A0 S4

System setting

Move tip clearance mm 10.0 Fix tip clearance mm

Second2 servo gun parameter

Case of selecting the next screen

Offset mm

150 225 300 350 Pressure-Current Tab.1 Gravitational

143938** Servo Gun 1 Param. ** A0 S4

Pressure-Current Tab.1 Gravitational

150 225 300 350

Check the abnormality of abrasion quantity

System setting

System setting

143938*Servo-gun Welding Data* A0 S4 Sequence common data

Welding condition Welding sequence Welding data copy

Common Data A0 S4

Number Output data Output type

Force 50Kgf

143938 *** Weld Sequence *** A0 S4

Number Condition signal

Squeeze signal

WI wait

Sequence

Source number

GUN2

Enter number and press SET 0.0

System setting

2 Arc

Arc Weld

Shield Gas state

Contents of the screen High step forward/backward setting

Inching speed setting

Palette slope calculation

Palletizing

143938 *** Palletizing *** A0 S4 Palletize pattern register

Use Number/UpDown and pressSET Previous Next

143938** Palletize pattern ** A0 S4 Pattern register

Pattern register

YES

Press SHIFT+-- Key Previous Next Complete

Basic pattern

System setting

Rec.PosiY Direct

Conveyor

Conveyor parameter setting

Conveyor

Conveyor angle/centr auto-set

143938** Conveyor Parameter ** A0 S4

Dsbl

Press SHIFT+-- Key Previous Next

System setting

System setting

Conveyor type

Automatic setting of the conveyor angle and center Outline

143938* Auto Conveyor Angle * A0 S4

12.0

Speed proportion voltage output

12.0V ∼ +12.0V

Pin arrangement of analog output terminal

143938 ** Speed by voltage ** A0 S4

Pin number Signal

Output

Port No

Selecting type of the robot Positioner group setting

System format

143938 *** System format *** A0 S4

System format

143938 *Robot type selection* A0 S4

Robot type selection

143938 *Robot type selection * A0 S4 H120 Matsushita motor

Enter number and press SET Previous Next

Make? Previous Next

No system file. Need to format first Previous Next

Cant delete! Check file protectionESC Previous Next

System setting

GUN 1 = 0 GUN 2 =

Use setting

143938 *** Usage setting *** A0 S4

ARC

Positioner group setting

143938 ** Positioner Group ** A0 S4

Additional Axis

Former times is ineffective

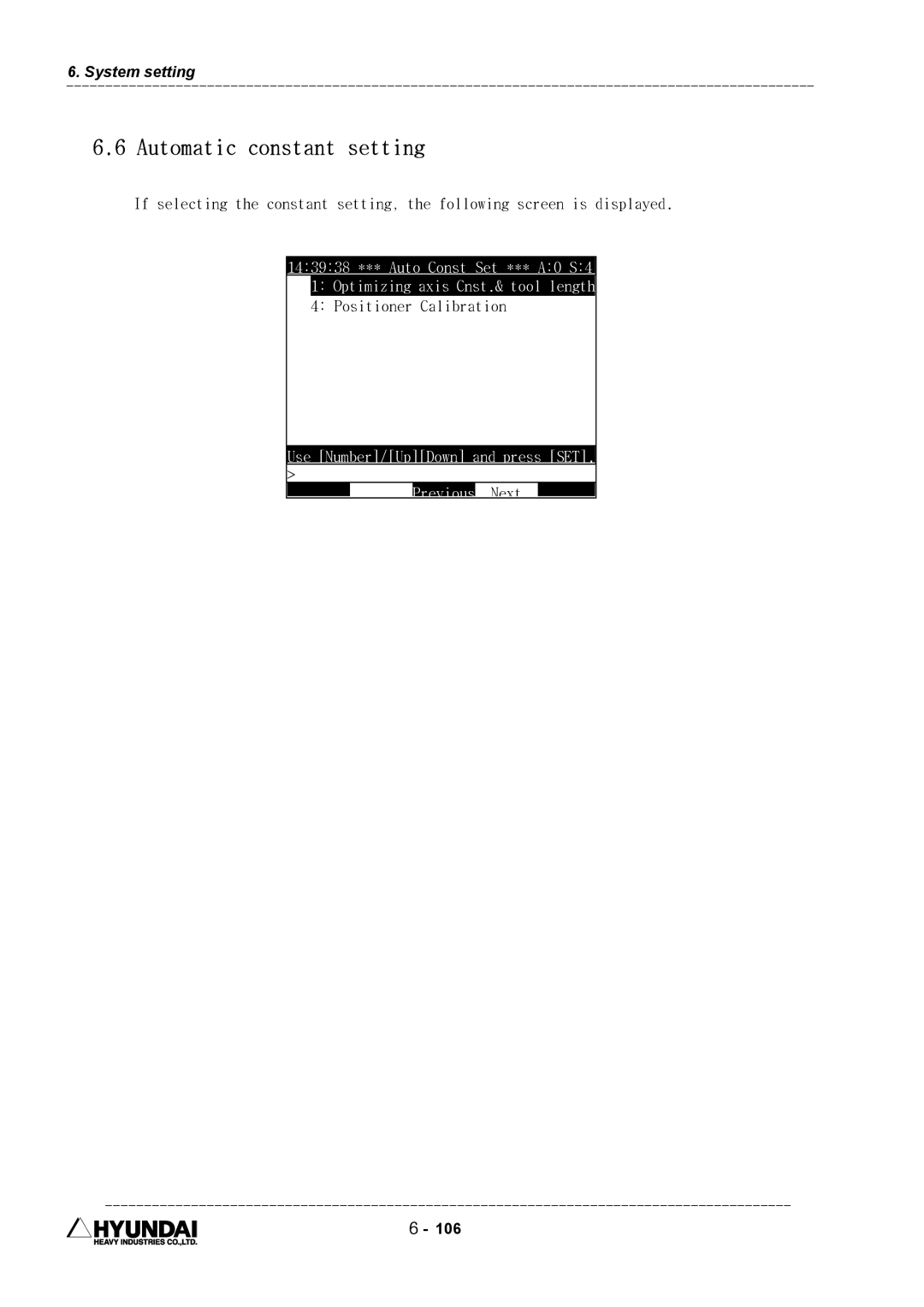

Automatic constant setting

Positioner Calibration

Max step position errorX =

Optimization of axis constant and tool length

System setting

You must setup the positioner GroupESC Previous Next

Positioner calibration

143938*Positioner Calibration*A0 S4

CP1 CP2

Constant is saved in the controller

DH.a= DH.alpha= DH.d= DH.theta=

143938*Positioner Calibration* A0 S4

000

Save?

Code

Set max. speed Step go/back

Enter R code No 0

Manual

1 R0 Step Counter Reset

2 R5 External Start Selection ENABLE/DISABLE

R5,0

3 R6 External Program Selection ENABLE/DISABLE

Set Ext program selectionDSBL=0,ENBL=1

R6,0

4 R10 RUN Time Display

Run Time Reset Outline All Data Clear

Run Time Clear

Clear YES / no

5 R17 File Name Display in Internal Memory

R18,0

6 R18 Frequency Condition Register DISPLAY/SETTING

Enter frequency register No 1

Enter register data 0

7 R29 Tool Number Setting

Enter tool No

R29,0

8 R44 Conveyor Data Clear

9 R45 Conveyor Register Manual Input

10 10 R46 Manual Conveyor Limit Switch on

Reference ⑴ It cannot be executed during operation

Enter speed rate 1

11 11 R49 Speed Variation Setting

PN999* S/F=3/1 Service

T O

12 12 R55 Palletize Counter Reset

End palletizing?

Rec speed type?Standard=0,%=1,mm/s=2

13 13 R71 Recorded Speed Specification Method Selection

Specify Sec

R71,0

143938 *** M a N U a L *** A0 SH4

14 14 R107 Program Head Data Display

15 15 R115 Program Copy

Use cursor Up/Down, then ESC for exit

Destination program to modify?

16 16 R116 Program Number Modification

Source program to modify?

R116,999

17 17 R117 Program Delete

Program to delete?

Delete?

Set robot lock DSBL=0,ENBL=1

18 18 R123 Robot Lock

Outline It sets the robot lock to ON/OFF

R123,0

19 19 R136 Modify Accuracy in Steps

„ If press

Reference

Enter MX No 1

Set MX signal Off=0, On=1

20 20 R137 Modify MX in Step

R137,0

R138,0

21 21 R138 Modify GUN in Step

Enter gun No

R138,1,0

23 23 R163 ON-LINE Shift Cancel

22 22 R162 Shift Register Value Change

24 24 R204 Spot Welding Condition Manual Output

Input discrete welding condition 0

Input binary WELDg condition 0

Enter gun number

26 26 R211 Squeeze Force Setting

25 25 R210 Servo GUN Number Selection

R210,1

Enter fix tip consumption. -10

27 27 R212 MOVING-TIP Consumption Preset

28 28 R213 FIXED-TIP Consumption Preset

R213,0.00

R219,1

30 30 R220 Equalizing Welder TIP Consumption Preset

29 29 R219 Equalizerless GUN Number Selection

R220,0.00

120

31 31 R245 Monitor Mode Selection

Monitoring

144 10 DIO145 168

Protect or Release?1Protect/2Release

32 32 R269 Memory Protection Setting

Program to protect?

Protect type?1Whole/2Section/3Playb

DSP2 S/W

33 33 R286 Software Version Display

DSP1 S/W

DSP3 S/W

R310,10

34 34 R310 Manual Output of GO-SIGNAL

Enter Group number 1

Input data to be output manually

35 35 R320 SET MAX. Speed of Step GO/BACK

Step GO/BACK speed? 1 255mm/s

R320,200

0DI Sig,1Analog,2Weld sticking0

Set reference point setting 0

36 36 R323 Robot Interrupt Function Record

R323

Enter reference Z -3000.0

Enter reference X -3000.0

Enter reference Y -3000.0

RobotH120, 6 axes, 1steps

M30,1

Example

Input minimum voltage. -10.0

M30=1,-5.00,5.00

Move P,S=100%,A=0,H=1

M30=1,-5.00,5.00,1

M30=1,-5.00,5.00,1,200.0,150.0

Reference ⑴ It can not be executed during operation

Backup execution code of controller?Y/N

37 37 R341 Execution Code BACK-UP

Programming

Programming

Modification of Step

Edit Step

Record of Step

Delete of Step

Summary of Operation Keys

Word Cursor Status

EN+PSTEP

Edition Screen

Edit Command

„ Command Area

„ Address Area

Example Move Sentence

Select interpolation type

Spd100.00

Command Input Select inputting command

Select command

RobotH6 6axes, 2steps

Enter pose

Local

Enter index1-999

Enter speed

Enter

P3+R2

Unit

Spd100.00 RobotH6

Adjust output optionToggle

Enter accuracy

2steps

To statement input status menu for sentence form constant

With numerical keys and menu

Sentence form

Pose form

Enter variable 120

Variable, numerical formula and string edit

Enter variable 120 Pose Shift Out

Enter variable

Enter variable V2%

SET

ENABLE+Ö SET

‘ +-*/=&~,%!$?`. @#₩ Smm/sec=V1%/2

Unit Conv

‘ Abcdefghijklmnopqrstuvwxyz

‘ abc efghkjklmnopqrstuvwxyz ‘ +-*/=&~,%!$?`.@#₩

Weld

Line number edit

SET

Line number is reflected on the edit frame

Goto S2

Block edit

Welding

Set start position of block region

Position of block region

V11!=0 S1 Move L,P1+R2,S=120mm/s,A=0,H=0

S2 Move L S=100mm/sec,A=0,H=0

Select block edit function

Copy Copied area is pasted just below a cursor

PN999* S/F1/2 Sp100.00 RobotH6 , 6axes, 14steps V10!=0

Select block edit function Unselect Copy Move Delete Close

PN999* S/F1/3 Sp100.00 RobotH6 , 6axes, 14steps V10!=0

Quick Open Function

Function Summary

Outline

Instructi

Remark

840.000 mm

Move step position

Pose of Current Step

960.000 mm

Welding Start Condition EXE. AT ASF#=x

143938** Arc Condition File **A0 S4

Save

Quick Open Function

Welding END Condition EXE. AT AEF#=

Condition File

Quick Open Function

ARC Auxiliary Condition File

Welding Auxiliary Condition Retry

143938** Arc Condition File **A0 S4

ASF

It starts with the current value of welding start condition

Welding Auxiliary Condition Restart

ARC Auxiliary Condition File Restart

Retry

Quick Open Function

Quick Open Function

Delay 30 sec

Welding Auxiliary Condition AUTO. Wire Stick Release

Auto Stick Recovery

20.0

Weaving Condition File

Select and Enter number. Press SET Previous Next Save

Quick Open Function

=30%,A=1,T=0

Program Edit in Running

HotE022/3/1

Select PF menu Escape Apply OK

143938*Servo-gun Welding Data*A0 S4 Welding condition

Spot Welding Function

Welding condition

Use Number/UpDownand press SET

Welding sequence

End wait time =0.00

Menu Tree

Chap Menu Tree

Menu List

Move, I/O

Grammar Input input direction , variable ,timeout time

Flow control

Endif

Jumpcall

REM Commemt

10.4 ETC

10.5 ARC

=voltage output valueVP=voltage ratio ,T=time ,ANTSTK

=100

Substitutional Statement

11.1.3

11.1.1

11.1.2

11.1.4

Execution setting

Signal input/output Jump, call, stop

DI1 signal output

M44 GI3 group signal output On-line shift M53

Character

Basic elements

Line

Address

Constant

H0 ∼&HFFFF

∼&HFFFFFFFF

S180 Flip Front

Robot type information

∼7 bit Bit Base R2180

Down Rear Auto

Variable

Global variable

Local variable

Input/output variable

System variable

RN1~RN16

Bit 1 start limit switchactive high

RN1~16

$CONVREG

Operator

Formula

Not Or XOR

Command line

Substitution

V2$= Emergency Stop

Robot Control Move Command

Until

Smove Command

∼3 0 is most accurate Tool

Print Command

Print #0, Signal Value =

11.2.3 I/O 11.2.3.1 I/O Substitution

#1 Serial port COM1 #2 Serial port COM2 Parameter

Input Command

Input #0 Teach Pendant

Arithmetic Variable, String variable

Program Flow Control Goto Command

Gosub ∼ Return Command

Call Command

11.2.4.5 on ∼GOTO Command

Delay Command

Wait Command

Stop Command

END Command

Stop If DI9=1 then

11.2.4.10 IF∼ELSEIF∼ELSE∼ENDIF Command

11.2.4.11 FOR∼NEXT Commands

Print Range Error END

Goto *RANGE

Endif Print

REM Spot Welding #1

ARC Welding Arcon Command

Comments

Arcon

Arcof Command

Arccur Command

Arcvol Command

Weavon Command

Arcdc Command

Arcdv Command

Weavof Command

Refp Command

Unsigned integer Number

Number of DI signal receiving interrupt

Print Command

Description Robot Interrupt I signal M29 Syntax

Others

Rinta Command

Parame Volt, interrupt occurs ∼10.0 Upper volt Ter

Spotcnd Command

Sreq Command

Sonl Command

Online coordinate conversion Slipping M53 Syntax

TONL1 Command

TONL2 Command

Number2,RF3=Basic Step number3 Start/End

Sreqt Command

Sxyz Command

SEA Command

Application of Search Dimension search

Teach Point Welding Line Search Range

Spot Command

Gunsea Command

Tierst Command

Call program to put in a insert sheet M94 Syntax

No,TP=Insert sheet Program

Palpu Command

PAL Command

Palend Command

Palrst Command

Palend P=1, ES=81

Callpr Command

Callpr

System Coordinate systems Number Example

Selcrd Command

∼10

Selcrd

MIT Code

ARC Welding

M101 1,JOB Finished

Function Arithmetic Function

Orderror

Timer

DEGRAD270

String Function

T Function Code

Spotcnd

T Function Code Example of corresponding HR Basic syntax

Palend P=1,ES=81

REM Spot Weld

Signal Connection

External Input Signal BD430/BD431

Plug-side 3M MDR 10140-3000VE HOOD10340-55F0-008

Use external power source

CNIN2 Input Signal

DI22/WI

General DI Signal DI1 ∼ DI18 signal connect as followings

Connect program selection signal as followings

Connect Discrete/Binary input signal as followings

※ Turn it on always

External Output Signal BD430, BD431

Output Circuit

BD430 Board Common voltage only

Connection Diagram BD431 Board Common + or voltage

Use external power source for power source

Set noise absorbing diode to a load

CNOUT2 Output signal

CNOUT2

GUN Signal

Reset

It is output when emergency stop is pressed

Step SET Alarm Signal

Error Time

Program ACK. Signal

Control Parameter →

It is out the confirming signal that robot is running

LOW Mode Signal

Robot Running

Robot Ready Signal

Robot Home Signal

Control Parameter 4. Home Position Registration

MDR

Specification of Connector

Maker Type Specification

20-Pin

Maker Type Specification