|

|

|

|

|

| Monitoring and Operating the Controller |

|

|

|

|

|

|

|

|

|

| Step | Operation |

| Press | Result |

| |

|

|

|

|

|

| Lower Display = A1S1VA = Alarm 1, Setpoint 1 |

|

|

|

|

|

|

| A1S2VA = Alarm 1, Setpoint 2 |

|

|

|

|

|

|

| A2S1VA = Alarm 2, Setpoint 1 |

|

|

|

|

|

|

| A2S2VA = Alarm 2, Setpoint 2 |

|

|

|

|

|

|

| NOTES: |

|

|

|

|

|

|

| With 3 position step control, alarms set for “output” will |

|

|

|

|

|

|

| not function. |

|

|

|

|

|

|

| MAN, RSP, AND FSAF selections do not have setpoint |

|

|

|

|

|

|

| values. |

|

| 3 | Change a value |

| or | To change any alarm setpoint value in the upper display. |

| |

| 4 | Return to Normal |

|

|

|

|

|

|

| Lower |

|

|

| ||

|

| Display |

| Display |

|

|

|

|

|

|

|

|

|

|

|

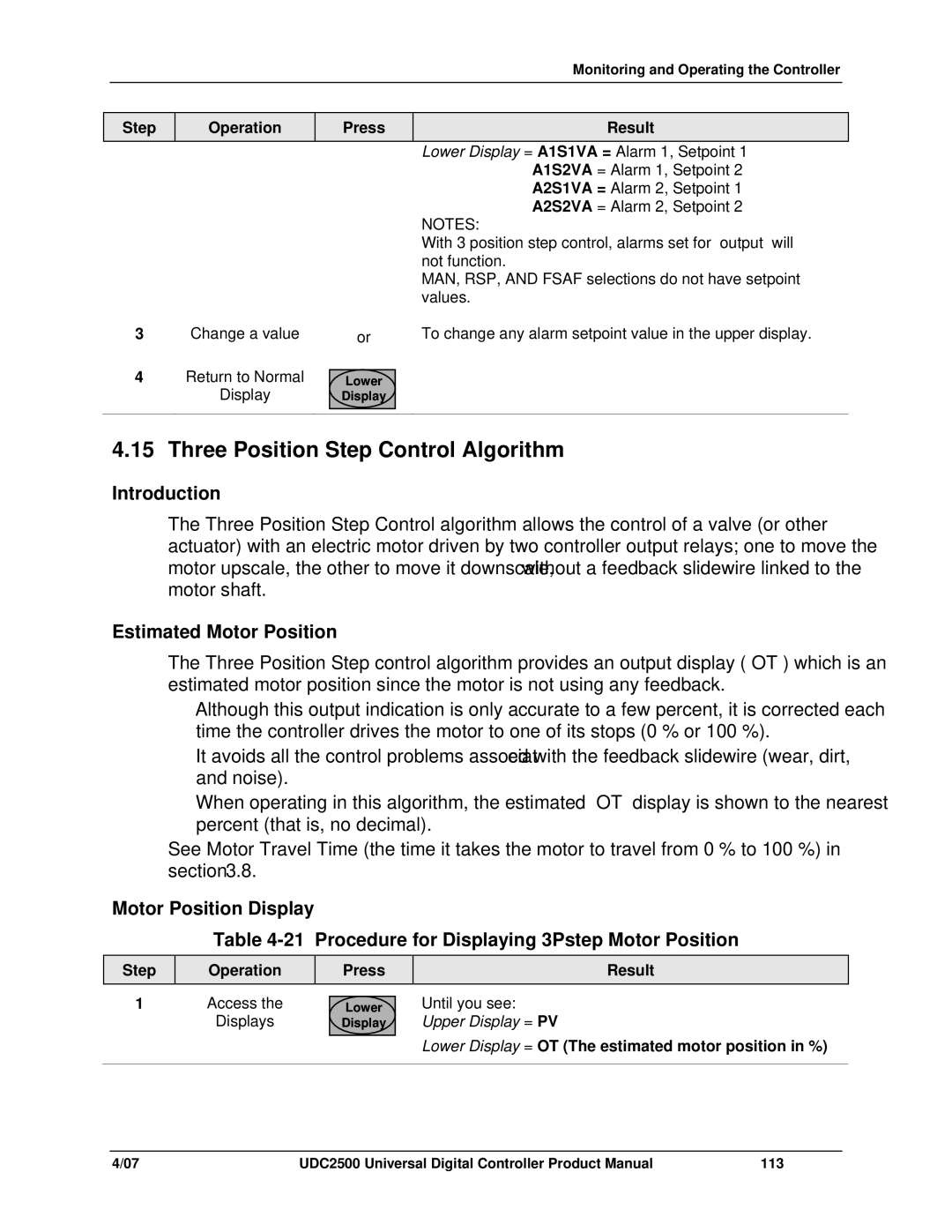

4.15 Three Position Step Control Algorithm

Introduction

The Three Position Step Control algorithm allows the control of a valve (or other actuator) with an electric motor driven by two controller output relays; one to move the motor upscale, the other to move it downscale, without a feedback slidewire linked to the motor shaft.

Estimated Motor Position

The Three Position Step control algorithm provides an output display (“OT”) which is an estimated motor position since the motor is not using any feedback.

•Although this output indication is only accurate to a few percent, it is corrected each time the controller drives the motor to one of its stops (0 % or 100 %).

•It avoids all the control problems associated with the feedback slidewire (wear, dirt, and noise).

•When operating in this algorithm, the estimated “OT” display is shown to the nearest percent (that is, no decimal).

See Motor Travel Time (the time it takes the motor to travel from 0 % to 100 %) in section 3.8.

Motor Position Display

Table

Step

Operation

Press

Result

1Access the

Displays

Lower

Display

Until you see:

Upper Display = PV

Lower Display = OT (The estimated motor position in %)

4/07 | UDC2500 Universal Digital Controller Product Manual | 113 |