Page

FLD=, FAND=, FAND, FAND, Fand

DVP-ES2/EX2/SS2/SA2/SX2/SE

Page

Contents

Communications

Appendix a

Series Model name

Page

PLC Concepts

PLC Scan Method

No Contact, NC Contact

Current Flow

Scan time exception

Reverse Current

PLC Registers and Relays

Ladder Logic Symbols

Creating a PLC Ladder Program

ORB ANB

TMR

2 LD / LDI Load no contact / Load NC contact

ANB Connect block in series

ORB Connect block in parallel

MPS / MRD / MPP Branch instructions

Branch Description Instruction Symbol

MPS

STL Step Ladder Programming

RET Return

S21 S22

Ladder Diagram

Conversion between Ladder Diagram and Instruction List Mode

Fuzzy Syntax

Common Programming Errors

Example Better method OK method

Example Good method Bad method

Or operation upward is not allowed Reverse current exists

Example

Correcting Ladder Diagram

LD T0 X2 ORB

Or T0

OUT Y0 Y1 and X0 OUT Y1

MPS OUT MPP

Example 1 Stop First latched circuit

Basic Program Design Examples

Example 2 Start First latched circuit

Example 4 Power down latched circuit

Stop

Example 3 Latched circuit of SET and RST

Example 6- Interlock control

Example 7 Sequential Control

Example 8 Oscillating Circuit

Example 12 Delay OFF Circuit

Example 9 Oscillating Circuit with Timer

Example 10 Flashing Circuit

Example 11 Trigger Circuit

Example 13 Output delay circuit

Example 14 Timing extension circuit

Example 15 Counting Range Extension Circuit

Green light

Timing Diagram

Green light Blinking

SFC Figure

Ladder Diagram

WPLSoft programming SFC mode

Memo

Programming Concepts

ES2/EX2 Memory Map

Specifications

Programming Concepts

Specifications

SS2 Memory Map

Specifications

Specifications

SA2 Memory Map

Specifications

Specifications

SX2 Memory Map

Specifications

Specifications

Status and Allocation of Latched Memory

STOP=RUN RUN=STOP

OFF=ON

Binary, Octal, Decimal, BCD, Hex

PLC Bits, Nibbles, Bytes, Words, etc

BCD

BIN OCT DEC

HEX

EX2 RUN Stop

Relay

Latch Default Function

M1052 Disable interruption I200

OFF PCC01

M1109 Y1 pulse output pause ramp down

M1141 For COM2 RS-485, Modrd / Modwr

M1203 C203 counting mode on count down

M1233 C233 counter monitor on count down

M1274 C239 counting mode on falling-edge

OFF YES

M1378 Indicate Slave ID#3 data interchange

Latch Default

Attrib Latch Default

Timer

Timers for Subroutines and Interrupts

Accumulative Timer

Counter

Bits Bits counters Counters

RST CNT OUT

Plus 1 or count down minus

OUT Y0

Applicable Software High Speed Counters

High-speed Counters

Applicable Hardware High Speed Counters

Phase 1 input high-speed counter Example

RST

Dcnt

Phase 2 inputs high-speed counter Example

MOV

AB-phase input high-speed counter Example

0FDB

Special Data Register

D1031 PV of Y0 pulse output High word

YES ’FFFF

COM2RS-485 Definition of start character STX ’3A

D1240 stores the low word of high-speed counter

D1314 Minute of RTC 00 ~

’1064

Link

D1442 Data length to be read on Slave ID#9

PLC Link

D1767 D1768 Data which is read from slave ID#10

DVP-PCC01

Nest Level PointerN, PointerP, Interrupt Pointer

14 E, F Index Registers

Index register E, F

Call

CJ P1

Call

Page

Applications of Special M Relays and D Registers

Function Group Watchdog Timer Number M1008, D1008 Contents

Number D1002 Contents

Function Group High-speed Timer Number M1015, D1015 Contents

Device Name Function

Function Group Number D1018~D1019 Contents

Number M1083,M1084, D1023 Contents

Number D1020 Contents

PLSY, Plsr

MTR, HKY, DSW, SEGL, PR

Incd

RAMP, Sort

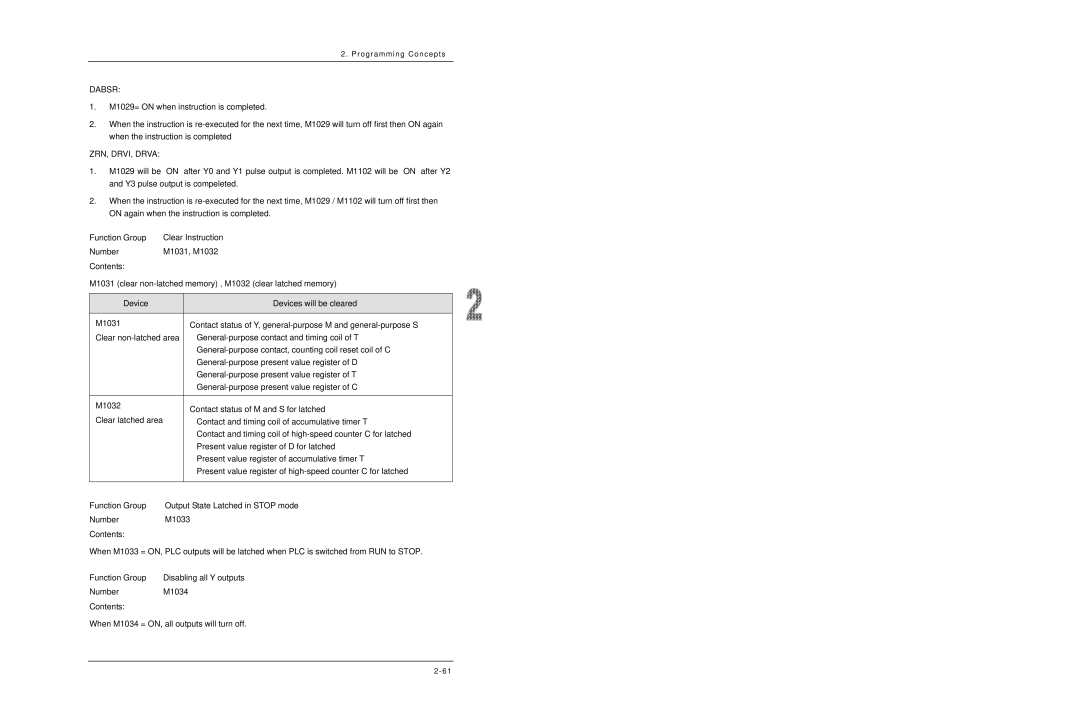

Dabsr

Number M1034 Contents

ZRN, DRVI, Drva

Device Devices will be cleared

Content

Function Group RUN/STOP Switch Number M1035 Contents

Port

COM1 COM2 COM3

COM3

Example 1 Modifying COM1 communication format

Example 2 Modiying COM2 communication format

Example 3 Modifying COM3 communication format

Example 4 RTU mode setting of COM1、COM2、COM3

Number D1038 Contents

Number M1037, D1037 Contents

Number D1062, D1110~D1113, D1116~D1118 Contents

Function Group Fixed scan time Number M1039, D1039 Contents

Device Function

0xF

Number M1119 Contents

Contents Device Explanation Latched

Error code explanation D1067 error code Function

STOP→RUN RUN→STOP

Number M1280, M1284, M1286 Contents

Number M1308, D1312 Contents

Number M1304 Contents

Number D1320~ D1327 Contents

Number M1346 Contents

Function Group PLC Link Number

Master PLC Slave ID

Read Write Out D100 D200

M1376 M1377 M1378 M1379 M1380 M1381 M1382 M1383

M1416 M1417 M1418 M1419 M1420 M1421 M1422 M1423

Page

Programming Concepts

Operation flow chart

Programming Concepts

SET MOV

Programming Concepts

Memo

Instruction Set

Basic Instructions without API numbers

Execution speed Instruction Function Operand Steps

ES2/EX2/SS2 SA2/SX2

LDI

Explanations to Basic Instructions

Connect NC contact Series Controllers

ANI

Connect no contact Parallel Controllers

ORI

ANB

Mnemonic Function Program steps

Connect a block in series Controllers

ORB

Points to note

Explanations Controllers

MRD

MPS

MPP

OUT

Latches the on Status Controllers

SET

Device Status

RST

MCR

Program End Controllers

END

NOP

No operation Controllers

Scan cycle

Interrupt Pointers

Pointers

P10

Fend

Iret

Timer Interrupts

External interrupt

Communication Interrupts

API

Application Programming Instructions

Mnemonic Operands Function Controllers

Type Bit Devices Word devices Program Steps

Explanation of the format of application instruction

Length of Operand 16-bit or 32-bit instruction

Operand Data format

Continuous execution vs. Pulse execution

Flags Bit instruction

Kn values Bit instruction

API 155 Dabsr

Limitations for times of using instructions

Numeric Values

Limitation of synchronized execution

Floating Point Operation

Assign Continuous Bit Numbers

Example 1 Represent 23 in 32-bit floating point value

Binary Floating Point

Example 2 Represent -23.0 in 32-bit floating point value

Decimal Floating Point

Bit 16-bit 32-bit

Instruction Set

Loop Control

Transmission Comparison

Four Arithmetic Operations

Data Processing

Rotation and Displacement

High Speed Processing

Handy Instructions

External I/O Display

Basic Instructions

Serial I/O

Falling-edge output Communication Instructions

PLF

Additional Instruction

Real Time Calendar

Positioning Control

Gray Code

Matrix Operation

Contact Type Logic Operation

DOR

223

S1 S2 Contact Type Comparison

Specific Bit Control

Numerical List of Instructions in alphabetic order

ABS Dabs

Absd Dabsd

Alternate state 218

Connect NC contact in parallel By specified bit 266

GPS data receiving 144

PLF

Pulse output Print Ascii code output

Stop VFD

Axis Relative Position Arc Interpolation 197

Single-Axis pulse output by 116

Range

Detailed Instruction Explanation

CJ P1

ON→OFF M4 OFF M4 OFF→ON

OFF→ON

M4 on

M4 on OFF

CNT

CALL, Callp 3 steps

Sret

Mnemonic Function

Subroutine Return

Descriptions Program Steps

INC

Mnemonic Function Disable Interrupt Controllers

Mnemonic Function Enable Interrupt Controllers

Iret

Interrupt Return

Flag Function

101

Fend

End of The Main Program First End

No contact to drive the instruction is required

CJ Instruction Program Flow

Call Instruction Program Flow

WDT, Wdtp 1 step

WDT

KnX KnY KnM KnS T For 3 steps

For K3 For K4 Next

TMR

CMP

ZCP

Mnemonic Operands Function

RST M0 RST M1 RST M2 Zrst M0 M2

KnX KnY KnM KnS T MOV, Movp 5 steps

Shift

Smov

PLC

CML

BMOV, Bmovp 7 steps

Bmov K1M0 K1Y0

DFMOV, Dfmovp

Fmov

XCH

BCD

BIN

103 102 101 Digit DIP switch in BCD format

Operation of flags

ADD

Zero flag

16-bit BIN subtraction

SUB

MUL

MUL D0 D10 D20

B00 B15

DIV

INC

DEC

Wand

D2 0

Dand

Logical Word or

WOR

DOR

Logical DWord or

Logical Word XOR

Wxor

Dxor

NEG

D0=2 0 0

ROR

ROL

RCR

RCL

KnX KnY KnM KnS T SFTR, Sftrp 9 steps

Sftr

Word Shift Right

Wsfr

Wsfrp K1X20 K1Y20

Word Shift Left

Wsfl

KnX KnY KnM KnS SFWR, Sfwrp 7 steps

Shift Register Read

Sfrd

KnX KnY KnM KnS T ZRST, Zrstp 5 steps

RST M0 RST T0 RST Y0

KnX KnY KnM KnS DECO, Decop 7 steps

D10 D20 B15 All be

All be B15

D10

SUM

BON

DMEAN, Dmeanp

Mean

ANS T10 K50 S999

Application example of alarm device production line

Instruction driven by contact is necessary

Points to note Flags

ANS

SQR

FLT

Apply FLT instruction to complete the following operation

FLT

KnX KnY KnM KnS T REF, Refp 5 steps

SET M1180

KnX KnY KnM KnS T REFF, Reffp 3 steps

MTR

MTR

Points to note

Hscs

Instruction Set

Page

Counting

Dhscs K100

Fend

Hscr

API Mnemonic Operands Function Controllers

HSZ

High Speed Zone

Compare Type Bit Devices Word devices Program Steps

Page

Dhsz

Program Example 1 Applying Hardware High Speed Counter

Speed variable

KnX KnY KnM KnS T SPD 7 steps

SA2/SE/SX2

⋅10 3 rpm n

Pulse Output

Plsy

CCW

200

Page

SET M1347 Plsy K1000 K1000 Y0

KnS PWM 7 steps

=1000ms Output Y1 =2000ms

Page

Pulse Ramp

Plsr

Page

Explanations on associated flags and registers

Frequency Increased/decreased Every shift 1000/20 Hz

Frequency Target

Explanations

Pulse

Explanations

KnX KnY KnM KnS T IST 7 steps

Sensor

Control panel

S10 S11 S12

S20 Y1

RET END

M1041

Flag explanation M1040

M1042

M1043

M1046

M1047

D1040~D1047

SER

Absd

Lower-bound value Upper- bound value Current value of C10

Bit Devices Word devices Program Steps

Page

KnX KnY KnM KnS T C Ttmr 5 steps

D0 unit sec Unit 100 ms

Stmr

Special Timer

X20 Y3 Stmr T10 K50 Y0

KnX KnY KnM KnS T ALT, Altp 3 steps

Ramp

If X20 = on

DTM

Data Transform

Move Type Bit Devices Word devices Program Steps

E f

+10

Instruction Set

+1 S S+2

Combination will be performed in the following rule

‘1’ ‘2’ ‘3’ ‘.’ ‘4’ ‘5’ ‘6’ 0x00

Program Example 2 K9

Program Example 1 K2, K4

Page

Data sort

Sort

Example table of data sort

TKY

BCD value 1-digit BCD code Overflow 103 102 101 BIN value D0

HKY

Input keys 0~9

PLCTransistor output

KnX KnY KnM KnS T DSW 9 steps

PLC

KnX KnY KnM KnS T SEGD, Segdp 5 steps

Segment with Latch

Segl

192

PLC

BCD value Output BCD code Signal output

194

Arws

Arrow switch

Arws

Ascii code conversion

ASC

KnX KnY KnM KnS T PR 5 steps

X20 drive signal

From

DFROM, Dfromp

ES2/EX2 SS2 SA2/SE/SX2

Rules for operand

Upper 16-bit Lower 16-bit CR #10 CR #9 Specified CR number

Program Example 1 COM2 RS-485

Mnemonic Operands Function Controllers Serial Communication

Program Example 2 COM2 RS-485

Bit mode

Receiving data External equipment PLC

STX

Program Example 3 COM2 RS-485

ADR

CMD

D120 high ‘0’ 30 H

Program Example 4 COM2 RS-485

Program Example 5 COM1 RS-232

Program Example 6 COM3 RS-485

Receving data External equipment→PLC

Flag Function Action

Special register Function

Modrd / Modwr / FWD / REV / Stop / Rdst / Rstef

Function Action

Modrd / Modwr / Modrw

Modrd / Rdst / Modrw

Modrd / MODWR/ Modrw

FWD / REV / Stop / Rdst / Rstef

REV / Stop / Rdst / Rstef / Modrw

Data sending and receiving will be started. When

Function Description

Setting

Protocol

Sending

Data

Errors

Receiving

Completed

FWD/REV/STOP/RDST/RSTEF

ETX1

ETX2

Value Error Description

M1130

M1126

COM Port I10 interrupt Special D

Ascii mode Field Name Descriptions

COM1

COM2

CR LF

RTU mode

Field Name Descriptions

Start

START/END

Example program of RS-485 communication

Field Name Data Hex

Reset in program

DPRUN, Dprunp

Prun

Asci

Convert Hex to Ascii

= Cdef H

When n is 6, the bit structure will be as

= Cdefh

When n is 4, the bit structure will be as

Instruction Set

Convert Ascii to HEX

Ascii code

Conversion

CDE H

Cdef H

DEF8 H

D20 D21

Check Code

CCD

Parity

Vrrd

Volume Read

Vrsc

Volume Scale Read

ABS

PID

Device Function Setup Range Explanation

Reverse control E = PV SV

Device Function Set-point range Explanation

Proportion for

PID Equations

MV = KP * Et + KI * EtS1 + KD * PV t S

⎢Et +

Position instruction

=40 SV=1 KP =20 KP =10 KP =5

Application

Step

PID

Example program of SV ramp up function

Part of the example program

From

Auto tuning area S3+4 = k3 PID control area S3+4 = k4

Instruction Set

PLS

Rising-edge detection operation

LDP

LDF

Rising-edge series connection

Andp

Andf

Rising-edge parallel connection

ORP

Falling-edge parallel connection

ORF

T5 K1000

TMR

C20 K100

CNT

C254 K1000

Dcnt

Inverse operation

INV

KnX KnY KnM KnS T C PLF 3 steps

Read Modbus Data

Modrd

Register Data Descriptions

Registers for received data responding messages

K100 D1129 Sett receiving timeout as 100ms

Modrd K1

FE H

Write Modbus Data

D1089 low ‘0’ 30 H

D1070 low ‘0’ 30 H

Register Data Descriptions

M1002 Set communication protocol as 9600, 8, E

VFD

FWD

Program Example COM2 RS-485

Register Data Descriptions

PLC

VFD, PLC sends 01 10 2000 0002 04 0012 01F4 C2

Data Descriptions

Error checksum LRC CHK

B, Uu, Nn, Abcd

HPF

GFF

Range of S1 K1 ~ K255

‘0’ 30 H Number of data count by word ‘5’ 35 H ‘D’ 44 H

Reset Abnormal VFD

Rstef

‘2’ 32 H ‘0’ 30 H Data address Data content ‘D’ 44 H

KnX KnY KnM KnS T LRC, Lrcp 7 steps

Register Data Explanation

08 0006 E7 CR LF

Remarks

KnX KnY KnM KnS T C CRC, Crcp 7 steps

01 06 0706 1770 66 AB

DECMP, Decmpp

Ecmp

DEZCP, Dezcpp

Ezcp

DMOVR, Dmovrp

Movr

RAD

DEG

DEBCD, Debcdp

Ebcd

Ebin

K314

DEADD, Deaddp

Eadd

DESUB, Desubp

Esub

DEMUL, Demulp

Emul

Ediv

EXP

125 Float natural logarithm operation

LOG

Dflt D0 D10 Dflt D2 D12

DESQR, Desqrp

Esqr

DPOW, Dpowp

POW

Dpow D10 D12 D20

KnX KnY KnM KnS T INT, Intp 5 steps DINT, Dintp 9 steps

SIN

Movp

COS

Degree value

TAN

TAN value

Asin

D11 D10 Asin value Binary floating point

DACOS, Dacosp

Acos

D11 D10 Acos value Binary floating point

Mnemonic Operands Function 135

Arc Tangent

DATAN, Datanp

DELAY, Delayp

General PWM output

DSWAP, Dswapp

Swap

Memr K10 D2000 K100

Writing the data into

PLC COM COM1 COM2 COM3

H0F

COM

COM1 RTU COM2 COM3 Ascii

Program Example 1 COM2RS-485, Function Code H02

Modrw

Ascii Mode M1143 = OFF

RTU Mode M1143 = on

Program Example 2 COM1RS-232 / COM3RS-485, Function Code H02

MOV

Program Example 3 COM2 RS-485, Function Code H03

COM2 COM1 COM3

D1256 Low byte ‘0’ 30 H

D1262 High byte ‘5’ 35 H

CF H

Program example 4 COM1RS-232 / COM3RS-485, Function Code H03

Modrw

Ascii mode COM3 M1320 = OFF, COM1 M1139 = OFF

Program example 5 COM2RS-485, Function Code H05

RTU mode COM3 M1320 = on COM1 M1139 = on

CMD 1,0 Control parameter

FF H

Program example 6 COM1RS-232 / COM3RS-485, Function Code H05

Program Example 7 COM2RS-485, Function Code H06

RTU mode COM3 M1320 = ON, COM1 M1139 = on

VFD-B Ö PLC, PLC receives 01 06 2000 1770

RTU mode M1143 = on

Program Example 9 COM2 RS-485, Function Code H0F

D1256 下 ‘0’ 30 H

PLC1 Ö PLC2,PLC1 sends 01 0F 0500 0010 02 34 12 21 ED

CB H

ED H

M1002 D1109 Set communication protocol as 9600, 8, E

Program Example 11 COM2 RS-485, Function Code H10

LRC CHK 0,1 is error check

EE H

PLC ÖVFD-B,PLC transmits 01 10 2000 0002 04 1770 0012 EE 0C

M1320 M1320 = OFF

DRAND, Drandp

Rand

Absr

TLC SON Absm Absr

Timing diagram of the operation of Dabsr instruction

Ex Mitsubishi MR-J2-A CR 8 reset

ZRN

Page

Time

Freq

Freq

Time

MOV K-2 D1312 RST M1308 SET M1346 Dzrn K20000 K1000 X4 Y0

Plsv

Drvi

M10 Ddrvi K20000 K2000 Y0

Page

Instruction Set

Drva

M10 Drva K20000 K2000

Page

Mnemonic Operands Function 160

Tcmp

Time compare

Mnemonic Operands Function Controllers 161

Tzcp

Time zone compare

Time addition

Tadd

KnX KnY KnM KnS TSUB, Tsubp 7 steps

D10 D20 05Hour

Normal D

Special D Content

Device Content Function

Device Content Range

RTC

Program Example Special D

Normal D Range

TWR

DMVM,DMVMP

MVM

Hour

Y10 Dhour K40000 D0

GRY

DGBIN, Dgbinp

Gbin

DADDR, Daddrp

Addr

Daddr D0 D2 D10

Subr

Dsubr D0 D2 D10

DMULR, Dmulrp

Mulr

Dmulr D0 D10 D20

Divr

When X23 = 0N, 16-bit data in D4 will be sent to D6 and D7

GPS data receiving

GPS data valid / invalid

GND

K2000 D1249 Set receiving time-out as 2s

Page

SPA

Page

M0 M1013 Dspa D4000 D5000

DWSUM, Dwsump

Wsum

Matrix

Mand

Fill 0 into the blank in R0C15-C8, R1C15-C8, and R2C15-C8

Matrix or

MOR

Mxor

Matrix XNR

Mxnr

Minv

Matrix compare

Mcmp

Mcmp

Matrix bit read

B47 Pointer D20

Matrix bit write

Before Execution After

Matrix bit shift

MBS

MBS

Matrix bit rotate

MBR

MBR

D10 12 M1098=0 D10 36 M1098=1

Ppmr

Draw a rhombus as the figure below

Dppmr

Axis Absolute Point

Dppma

Cimr

Quadrant

Draw an ellipse as the figure below

Draw a tilted ellipse as the figure below

Points to note

Cima

Dcima

RST

Ptpo

Dptpo D0 D300 Y0

Cllm

Close Loop Explanations

Instruction Set

100kHz X4 = OFF -- on

Assume the first execution results are as below

Points to note

Reset after CH0 Y0, Y1 pulse output is completed

Vspo

Freq Time Pulse number

Function Explanations

Freq T2=11kHz

Instruction Set

Mnemonic Operands Function 199

ICF

Immediately change frequency

Interrupt

M0=ON X6=ON X7=ON

Dvspo

Destination value

Scal K500 K-168 K534 D10

Device No Parameter Range Integer S2、S2+1

Device No Parameter Range

Floating point number

= kx + b

Destination value Max. Destination value Source value

Destination value =500 Source value

Dmovr F200 D2 Dmovr F500 D4 Dmovr F30 D6

Cmpt

Cmpt

Asda servo drive

Program example 1 COM2 RS-485

Asdrw

Program example 2 COM3RS-485

COM2 COM3

Csfo

Catch speed

Proportional output

Csfo X1 D0 D10

DLD

Serial Type Logic Operation

AND#

Dand

219

OR#

Operands S1 Source device S2 Source device Explanation

222

LD※

Dand =

Dand >

Dand <

Parallel Type Comparison

OR※

Executes output on Y1 When D0 = k2, executes output on Y2

K4Y0 D0 When D0 = k1

Bout

Bout

Bset

Bset

Brst

K4Y0 D0 When D0 = k1 Y1 is OFF When D0 = k2 Y2 = OFF

Program Example Instruction Operation

Load no contact

BLD

BLD

K3 Load no contact with bit

Status of bit3 in D0

Bldi

Bldi

K1 Load NC contact with bit

Status of bit1 in D0

Band

Band

Bani

Bani

K0 Connect NC contact in series

BOR

BOR

K0 Connect no contact

Defined by bit0 of D0

Bori

Bori

K0 Connect NC contact

FLD =

FLD※

FLD >

FLD <

Fand >

Fand =

Fand <

Fand <>

For =

For >

For <

Memo

Communications

Communication Ports

CMD Command code and Data

Communication Protocol Ascii mode

END1

END0

PC→PLC

CMDHex Explanation Device

Ascii

END CR LF

LRC CHK checksum

Exception response

Exception Explanation Code

Communication Protocol RTU mode

Start

Address Communication Address

Field Name Example Hex

CRC CHK check sum

Exception response

Modbus

PLC Device Address

ES2/EX2 SS2 SA2/SE

SX2

A710~AEDF

ETX

Command Code

Ascii

Command Code 03, Read Content of Register T, C, D

Command Code 05, Force ON/OFF single contact

Force Data Lo Error Check LRC

Command Code 15, Force ON/OFF multiple contacts

0DHex

Memo

Sequential Function Chart

Step Ladder Instruction STL, RET

Sequential Function Chart SFC

STL

RET

SFC

Features

S21 S22 S23

Operation of STL Program

Actions of Step Points

STL Transition

Repeated Usage of Output Coil

Transfer of Step Points

Repeated usage of timer

SET Sn

OUT Sn

S24 OUT

Restrictions on Using Certain Instructions

LD/LDI/LDP/LDF AND/ANI/ANDP/ANDF ANB/ORB

OR/ORI/ORP/ORF MPS/MRD/MPP INV/OUT/SET/RST

MC/MCR

S41 S42 S43

Points to Note for Designing a Step Ladder Program

Device Description

Types of Sequences

SFC diagram

S21 S42 S43

S20 S21 S22 S23 S24

S40 S41 S42 S50

Example of alternative divergence & alternative convergence

Step Ladder Diagram SFC Diagram

Step Ladder Diagram

S20 Y0 S30 S31 S32 S40 S41 S42 S50

S40

S20 S30 S31 S32 S40 S41

Restrictions on Divergence Sequence

S20 S30 S31 S32

IST Instruction

IST

Initial State

Sensor

SET

X35

S70 S80 Y3

RST

Memo

Troubleshooting

Common Problems and Solutions

Error LED is

Flashing

Troubleshooting

Error code Description Action

Error code Table Hex

Select programming

Error Check Description Drop Latch

Error Detection Devices

Device D1067 Description Error Code

Stop Æ RUN RUN Æ Stop

CANopen Function and Operation

Storage Data type

Introduction of CANopen

Sint Usint Byte

INT Uint Word

Lint Ulint Lreal Lword

Installation and the Network Topology

CAN+ CAN-H Can CAN-L

¾ The can signal and the data frame format

¾ The topology structure of the CANopen network

¾ The can network endpoint and the topology structure

Bit/second

Transmission rate

Maximum

Communication

TAP-CN02

TAP-CN01

Introduction of the CANopen Protocol

CANopen Protocol

¾ The object dictionary

CANopen Communication Object

¾ PDO process data object

Type PDO transmission

RTR

PDO1

COB-ID

Byte Object Data Identifier ¾ SDO service data object

LSB MSB

Request code Description Hex

— Module control services

Initialization Pre-operational Operational Stopped

PDO SDO Sync

— Error control services

Command specifier Function Hex

Emcy

NMT

— Emergency object

— Boot-up services

Predefined Connection Set

Object Function code

PLC device Mapping area Mapping length

Data Structure of SDO Request Message

PLC device Request message High byte Low byte

PLC device Response message High byte Low byte

Status code Explanation

0B~FF

PLC device Response message High byteHex Low byteHex

PLC device Request message High byteHex Low byteHex

Data Structure of NMT Message

NMT service code Hex Function

Data Structure of Emergency Request Message

Example 1 Stop slave of No through NMT

82(hex)

¾ Hardware Connection

DVP32ES2-C

¾ Editing the Ladder Diagram through WPLsoft

¾ RUN indicator LED indicator Description How to deal with

Indicators and Troubleshooting

CANopen Network Node State Display

LED indicator Description How to deal with

D9989 D9990 D9991 D9992 D9993 D9994 D9995 D9996 Register

Code Indication How to correct

Code Indication How to correct

Parameter Setting Explanation

¾ Setting Servo Parameters

Application Example

¾ Hareware Connection

Explanation Default

¾ Setting CANopen Baud Rate and Node ID of DVP-ES2-C

DVP-ES2-C

Explanation Default

¾ Network Scanning

¾ Node Configuration

Page

Transmission Type Description Remark

Synch

Asynch

Program explanation

COB-ID Sync

Object Dictionary

DVPES2C

COB-ID Emcy

Index Subindex Object name Data type Attribute Default value

Index Subindex Object name Data type Attribute Default value

Index Subindex Object name Data type Attribute

Index Subindex Object name Data type Attribute Default value

Index Subindex Object name Data type Attribute Default value

Index Subindex Object name Data type Attribute Default value

Index Subindex Object name Data type Attribute Default value

Appendix

An introduction of installing the USB driver in the PLC

Installing the driver

Installing the USB Driver

Appedndix a