Product Guide

Page

Preface

Page

Table of Contents

Design Architecture

Table of Contents M2488 Product Guide

Scsi Messages

Tape Unit Scsi Commands

Table of Contents

Receive Diagnostic Results Factory Mode

Receive Diagnostic Results Check Condition

Send Diagnostic Factory Mode Check

Tape Unit Parameters

Media Changer Scsi Commands

MC Medium Changer INQUIRY/CHANGE Definition

Additional Command Information on Medium Changer

Tape Processing

Maintenance and Servicing

Xii C144-E019-03EN

Parts Replacement Catalog

Parameter List Diag Result Data

M2488 Product Guide List of Figures

List of Figures

Top Cover

List of Figures M2488 Product Guide

M2488 Product Guide List of Tables

List of Tables

List of Tables M2488 Product Guide

C144-E019-03EN Xix

List of Tables

C144-E019-03EN Xxi

Xxii C144-E019-03EN

C144-E019-03EN Xxiii

Xxiv C144-E019-03EN

Preparing the M2488 and ITS Optional Equipment

Chapter Installation Instructions

Configurations

Introduction

Rack-mount Configurations

Installation Instructions M2488 Product Guide

Rack-mount

Desktop

Desktop Configurations

IPM

Unpack the M2488 Tape Drive

Unpacking Instructions

ACL

Unpack the Automatic Cartridge Loader

Facl

Unpack the Flush-mounted Automatic Cartridge Loader

Inspect the Facl

Equipment Inspection

Inspect the M2488 Tape Drive

Inspect the ACL

FACL?

Assembly Instructions

IPM

Interface Personality Module Installation

Step Action

See Figure

Cable and Power Connections

Drive with ACL Attached 5-Cartridge Magazine

Desktop Installation Instructions

Tools Required

Tape Drive Only

Attaching Bases

Drive with ACL Attached 10-Cartridge Magazine

Stability Brackets

Drive Positioning

M2488 with Facl in Desktop Model

Drive with Facl Attached

10. Attach to Bottom Base

11. Desktop Model Top Covers

12. Desktop Model Rear Cover

5.2.1 Inner Cover Mounted to Mounting Tray

Rack-Mount Installation

5.2 Adjust the Guide Plate

5.1 Tools Required

Attach Mounting Tray

13. Guide Plate Installation Screw Plate Mounting

14 -inch Rack-mount Kit Installation

15. Bracket Adjustment

Adjust the Brackets

16. M2488 Tray Mounting

17. M2488 with ACL Tray Mounting

19. Facl Face Plate

Equipment and Tools Required for ACL Installation

Installation of the Automatic Cartridge Loader

Equipment Part Number Quantity Description ACL

20. Prepare the M2488 Tape Drive

Prepare the M2488 Tape Drive

21. Prepare the ACL

Prepare the ACL

22. Connect the M2488 and the ACL Base

Connect the M2488 and the ACL

23. Attach Operator Panel Cable to ACL Base

Excess cable

25. Replace Covers

Equipment and Tools Required for Facl Installation

Installation of the Flush-mount Automatic Cartridge Loader

Equipment Part Number Quantity Description Facl

26. Prepare the M2488 Tape Drive

27. Prepare the Facl

Prepare the Facl

28. Facl Rear Connect the M2488 and the Facl

29. Connect the M2488 and the Facl

31. Replace Top Covers

Preparation for USE

Page

2OPERATION of the M2488

Chapter Design Architecture

Data Path

Erdc Compression Feature

Operation of the Magnetic Tape Controller MTC

Design Architecture M2488 Product Guide

Microprocessor Control

M2488 Product Guide Design Architecture Scsi BUS

Firmware

Operation of the Magnetic Tape Unit MTU

Airless Tape Path

PCA-OP

PCA-DVL

CG00000-011503 REV. a April

M2488 Scsi Messages

Chapter Scsi Messages

M2488 Tape and Medium Changer Scsi Messages

M2488 Product Guidescsi Messages

Abort code 06h

BUS Device Reset code 0Ch

Command Complete code 00h

Scsi Messages M2488 Product Guide

Code Message Length Bytes

M2488 Product Guide Scsi Messages

Extended Message Format code 01h

Synchronous Data Transfer Request Sdtr

Supported Scsi transfer rates are listed in Appendix G

Bits Bytes

Wide Data Transfer Request Wdtr

Scsi Messages M2488 Product Guide

Ignore Wide Residue code 23h

Identify code 80h-FFh

Byte Value Description

Message Parity Error code 09h

Initiator Detected Error code 05h

Linked Command Complete code 0Ah

Linked Command Complete with Flag code 0Bh

No Operation code 08h

Restore Pointers code 03h

Save Data Pointer code 02h

Scsi BUS Status

Reservation Conflict Status

Page

Chapter

Tape Unit Scsi Commands

Logical Units and Scsi IDS

Command Description Paragraph Code

M2488 Tape Scsi Commands

Tape Unit Scsi Commands M2488 Product Guide

M2488 Scsi Commands

M2488 Product Guide Tape Unit Scsi Commands

CDB Field Description

Command Description Block Format

Field Description

Bits Bytes LUN

Change Definition command 40h

Change Definition CDB Description

Change Definition Field Description

Change Definition Changes

Definition Parameter Description

Value Meaning of Definition Parameter

Change Definition Sense Keys

Change Definition Check Condition Status

Sense KEY Condition Description

Display Field Description 11h

Display CDB Description 11h

Display Parameter 11h

Display Data 11h

Display Parameter Field Description 11h

Space

Display Data

Display Sense Keys 11h

Display Mode Selection Bits 11h

Qualifier Description

10. Display Field Description 10h

Display CDB Description 10h

LUN

Display Data 10h

11. Display Format Control Byte Description 10h

12. Display Parameter 10h

4.3 Display Sense Keys 10h

13. Display Mode Selection Bits 10h

Immed BIT Long BIT Action Taken

Erase command 19h

Erase CDB Description

14. Erase Field Description

Not Ready

Erase Sense Keys

Data Protect

Aborted Command

Evpd

Inquiry command 12h

Inquiry CDB Description

15. Inquiry Field Description

Inquiry Data

16. Evpd Bit

17. Supported VPD Page Codes

Inquiry Check Condition Status

18. Inquiry Data Format

19. Inquiry Data Format Field Description

Inquiry Data Format Field Description

LUN Peripheral Description Qualifier Device Type

20. Peripheral Qualifiers

21. Peripheral Device Type

Code Description

MTU Fujitsu

23. Default Vendor and Product Identification Fields

Inquiry Sense Keys

LUN Vendor ID Controller LUN Product ID

7.1LOAD Unload CDB Description

Load Unload command 1Bh

24. Load Unload Field Description

Load Unload Check Condition Status

Medium Changer

GAL Request

Load Unload Sense Keys

LSB

Locate command 2Bh

Locate CDB Description

25. Locate Field Description

26. Block ID Format

Locate Field Description

27. Block ID Format Field Description

28. Format Mode Values

Format Code Value

Locate Sense Keys

Locate Check Condition Status

LOG Select Check Condition Status

LOG Select command 4Ch

LOG Select CDB Description

29. LOG Select Field Description

LOG Sense CDB Description

LOG Sense command 4Dh

30. LOG Sense Field Description

Field in CDB

BUS Device Reset

31. Page Codes

LOG Sense Operation

32. Log Page Format

LOG Sense Parameters

34. LOG Parameter Field Description

33. Log Parameter Format

ETC=0

36. Log Sense Page 00h, Supported Log Pages

Default Bytes Value

Write Errors Detected by Firmware

37. Log Sense Page 02h, Error Counter Page Write

Bits Default Bytes Value

Write Errors Recovered by ECC

Total Tapemarks Written

Bits Default Bytes Value Bytes Transferred from Initiator

TMC=0

Total Write Blocks

Read Errors Detected by Firmware

38. Log Sense Page 03h, Error Counter Page Read

Bits Default Bytes Value Erase Gaps DUE to Retry

Read Errors Recovered by ECC

Total Read Blocks That Were Recorded in Edrc Format

Total Errors Corrected

Total Read Forward Bytes

Bytes Transferred to Initiator

Read Retries

Total Read Blocks That Were not Recorded in Edrc Format

39. Log Sense Page 0Ch, Sequential-Access Device

Error Statistics by Track

40. Log Sense Page 31h, Track Error Statistics

Log Sense Page 31h, Track Error Statistics

136

175

LOG Sense Sense Keys

Loop Write to Read CDB Description

Loop Write to Read command C1h

41. Loop Write to Read Field Description

Loop Write to Read Sense Keys

Hardware Error

Volume Overflow

Loop Write to Read Check Condition Status

Byte BIT Valu Description

Mode Select command 15h

Mode Select CDB Description

42. Mode Select Field Description

43. Mode Select Parameter List Format

Mode Select Data

45. Mode Select Parameter Header Field Description

47. Block Descriptor

46. Buffered Mode Values

Buffered Description Mode

Block Descriptor

Descriptor 49. Page Descriptors

Block Descriptor Field Description

50. Page Descriptor Field Description

Mode Select Sense Keys

Mode Sense CDB Description

Mode Sense command 1Ah

51. Mode Sense Field Description

52. PC Field

Mode Sense Data

Mode Sense Data Header 53. Mode Sense Data Header

Bits Default Bytes

55. Buffered Mode Description

54. Mode Sense Data Header Field Description

56. Block Descriptor

57. Mode Select Parameter Header Field Description

Descriptor 58. Page Descriptors

Initiator Setup

Mode Settings

59. Page Descriptor Field Description

M2488 Product Guide Tape Unit Scsi Commands

Mode Sense Sense Keys

Sili

Read command 08h

Read CDB Description

60. Read Field Description

Read Check Condition Status

Fixed Sili Block Description BIT Mode

Are both set to one

No Sense

Read Sense Keys

Blank Check

Read command was aborted

62. Read Block Limits Data

Read Block Limits command 05h

Read Block Limits CDB Description

61. Read Block Limits Field Description

Read Block Limits Sense Keys

Read Buffer CDB Description

Read Buffer command 3Ch

63. Read Buffer Field Description

Byte Mode Implemented BIT

64. Read Buffer Command Mode

Vendor Unique Mode 001b and Data Mode 010b

65. Supported Buffer ID Values for Read Data Mode

67. Read/Write Nvram Descriptor buffer ID

Descriptor Mode 011b

68. Descriptor Mode Field Description

66. Read/Write Data Buffer Descriptor buffer ID

Boundary Offset Boundary Buffer Offsets

69. Offset

Read Buffer Sense Keys

17.1READ Position CDB Description

Read Position command 34h

70. Read Position Field Description

Bits Bytes BOP EOP

Read Position Return Data

MSB

Byte BIT Description

71. Read Position Return Data Description

72. Block ID Field Description

17.3 Description of Block ID Format

73. Format Codes

Read Position Sense Keys

18.1READ Reverse CDB Description

Read Reverse command 0Fh

74. Read Reverse Field Description

Invalid Field in CDB

Read Reverse Check Condition Status

Read Reverse Sense Keys

Receive Diagnostic Results CDB Description

Receive Diagnostic Results command 1Ch

75. Receive Diagnostic Results Field Description

Routine Parameter Code List Length

76. Receive Diagnostic Parameter List Length Field

79. Page 00h Supported Diagnostic Pages

Diagnostic Page Codes PF=1 in Send Diagnostic command CDB

77. Diagnostic Page Codes

78. Receive Diagnostic Results Page, General Form

81. Page 80h Field Description

Receive Diagnostic Results Check Condition Status

82. Online Diagnostic Results data Parameter List

Receive Diagnostic Results Sense Keys

Mode

Receive Diagnostic Results Factory Mode command 1Ch

Receive Diagnostic Results Factory Mode CDB Description

84. Receive Diagnostic Results Field Description

Routine Parameter Code List Length

87. Receive Diagnostic Results Page, General Form

86. Diagnostic Page Codes

88. Page 00h Supported Diagnostic Pages Factory Mode

00h Supported Diagnostic Pages Factory Mode

90. Page 80h Field Description

92. Page 81h Field Description

90-9Fh Online Diagnostic Test

95. Online Diagnostic Results data Parameter List

Receive Diagnostic Results Sense Keys

Bits Bytes Sili LUN

Recover Buffered Data command 14h

Recover Buffered Data CDB Description

97. Recover Buffered Data Field Description

Recover Buffered Data Check Condition Status

Recover Buffered Data Operation

Recover Buffered Data Sense Keys

22.1 Release Unit CDB Description

Release Unit command 17h

98. Release Unit Field Description

Release Unit Sense Keys

Release Unit Operation

Request Sense Check Condition Status

Request Sense command 03h

Request Sense CDB Description

99. Request Sense Field Description

Request Sense Sense Keys

Report Density Support CDB Description

Report Density Support command 44h

Report Density Support Data

100. Report Density Support Field Description

April CG00000-011503 REV. a 107

108 CG00000-011503 REV. a April

Ucts is discouraged since the definition of bits may vary

104. Report Density Support Data Block Field Description

110 CG00000-011503 REV. a April

Report Density Support Sense Keys

Reserve Unit CDB Description

Reserve Unit command 16h

105. Reserve Unit Field Description

Reserve Unit Operation

Reserve Unit Sense Keys

Rewind Check Condition Status

Rewind command 01h

Rewind CDB Description

106. Rewind Field Description

Rewind Sense Keys

Send Diagnostic CDB Description

Send Diagnostic command 1Dh

107. Send Diagnostic Field Description

108. Send Diagnostic CDB Field Description Overview

Send Diagnostic Field Description

Routine Selftest Devofl Unitofl Parameter Code List Length

Send Diagnostic Check Condition Status

Send Diagnostic CDB Field Description Overview

Diagnostic Pages PF=1

110. Diagnostic Page Codes

109. Send Diagnostic Page, General Form

111. Page 00h Supported Diagnostic Pages

Description of the Page Code 80h

112. Page 80h Online Diagnostic Test

113. Diagnostic Parameter List

Diagnostic Parameter List PF=0

Send Diagnostic Sense Keys

114. Send Diagnostic Factory Mode Field Description

Send Diagnostic Factory Mode command 1Dh

Send Diagnostic Factory Mode Field Description

Send Diagnostic Factory Mode Check Condition Status

Description of Page Code 00h

116. Send Diagnostic Page, General Form

117. Diagnostic Page Codes

118. Page 00h Supported Diagnostic Pages

Description of Page Code 80h

119. Page 80h Online Diagnostic Test

Description of Page Code 81h

120. Page 81h Manufacturing Online Diagnostic Test

Value of 1 is used to select Edrc Clear data transfer mode

Description of Page Codes 90-9Fh

122. Page 90-9Fh MTU Online Diagnostic Test

List

Diagnostic Parameter List PF=0

124. Diagnostic Parameter List

134 CG00000-011503 REV. a April

126. Code Field Bits

Space command 11h

Space CDB Description

125. Space Field Description

End-of-Tape Parameter

Space Check Condition Status

Filemark Parameter

End-of-Data Parameter

Space Sense Keys

Test Unit Ready Check Condition Status

Test Unit Ready command 00h

Test Unit Ready CDB Description

127. Test Unit Ready Field Description

Test Unit Ready Sense Keys

Write Check Condition Status

Write command 0Ah

Write CDB Description

128. Write Field Description

Sense Data Information Bytes

Buffered Mode

Early Warning Indication

Deferred Write Errors

Additional Information

Write Sense Keys

32.1WRITE Buffer CDB Description

Write Buffer command 3Bh

129. Write Buffer Field Description

Mode Bits Implemented Modes

130. Write Buffer Modes

Buffer ID Description Capacity

M2488 Product Guide Tape Unit Scsi Commands

Write Buffer Check Condition Status

Microcode has Been Changed

Write Buffer Sense Keys

Write Filemarks CDB Description

Write Filemarks command 10h

132. Write Filemarks Field Description

Write Filemarks Check Condition Status

133. Write Filemark Command Operations

Buffer Immed Operation Mode BIT

Buffer Block Information Field Mode

Write Filemarks Sense Keys

Blank Check Aborted Command

Scsi Reset

Command Disconnection

Page

Parameters Savable Bit All pages

Chapter Tape Unit Parameters

M2488 Product Guide Tape Unit Parameters

Codes

00 -Vendor Unique Parameter Field Description

Vendor Unique Parameter 00 Vendor Unique Parameter

Played on the op panel display

Tape Unit Parameters M2488 Product Guide

Error Recovery and Reporting Parameters

01 Error Recovery and Reporting Parameters

Error Recovery and Reporting Parameters Field Description

State of the other error recovery flags

EER PER DTE DCR Description

Valid Combinations of Error Recovery Parameters

Dtdc

Disconnect/Reconnect Control Parameters

02 Disconnect/Reconnect Parameters

02 Disconnect/Reconnect Parameters Field Description

Data Transfer Disconnect Control

Eeca

Rlec

Chronous event notification

EEG SEW

Bytes

DBR BIS

AVC Socf RBO REW

Is changed to the value specified in the active format field

10h Device Configuration Parameters Field Description

EOM

Density Code 28h

Density Code Description

7.1 M2488 Operation When Density Code 28h Is Not Configured

7.2 M2488 Operation When Density Code 28h Is Configured

When the Following is True Mode Sense will Report

Tape Unit PARAMETERSM2488 Product Guide

18. VPD Page Format

MTU INQUIRY/CHANGE Definition Vital Product Data Pages

17. Supported MTU VPD Page Codes

General VPD Page Format

19. VPD Page Format Field Description

21. Inquiry Data Format VPD Page 80h Unit Serial Number

Supported VPD Pages Page 00h

20. Inquiry Data Format VPD Page 00h Supported VPD Pages

Unit Serial Number Page Page 80h

23. Inquiry Data Format VPD Page 81h Field Description

Implemented Operating Definition Page Page 81h

25. Inquiry Data Format VPD Page 82h Field Description

Ascii Implemented Operating Definition Page Page 82h

Ascii

26. Inquiry Data Format VPD Page C0h Unit Usage

Unit Usage Page Page C0h

27. Inquiry Data Format VPD Page C0h Field Description

Drive MTU Factory Configuration Settings

Configuration Page Page C1h

28. Inquiry Data Format VPD Page C1h Configuration

Drive MTU Configuration Settings

30. Inquiry Data Format VPD Page C0h Field Description

Controller Target Configuration Settings

Product Identification Page Page C2h

29. Inquiry data format VPD Page C2h Product Identification

Commands for Medium Changer Devices

Chapter Media Changer Scsi Commands

Media Changer Commands

M2488 Product Guide Media Changer Commands

Exchange Medium MC command A6h

Media Changer Commands M2488 Product Guide

Exchange Medium CDB Description

Source First Second Result Destination

Exchange Medium Examples

M2488A11 ACL Exchange Medium Examples

M2488A12 Facl Exchange Medium Examples

GAL Request

Exchange Medium Sense Keys

Mand

Aborted COM

Mode Select Field Description

Mode Select MC command 15h

M2488 Product Guide Media Changer Commands

Mode Select Parameter List Format

Mode Select Check Condition Status

Descriptor Field Description

Mode Select Parameter Header

Mode Select Mode Parameter Header

Descriptors

Mode Select MC Sense Keys

Media Changer COMMANDSM2488 Product Guide

Mode Sense Field Description

Mode Sense MC command 1Ah

PC Field Description Bits

10. PC Field

13. Page Descriptors

11. Mode Sense Data Header

12. Mode Sense Data Header Field Description

Descriptor

Mode Sense MC Sense Keys

14. Mode Sense Page Descriptors Field Description

Unit Attention

Move Medium CDB Description

Move Medium MC command A5h

15. Move Medium Field Description

16. XCL Allowed Moves

4.2 ACL/FACL Tables of Allowed Moves

Source Address Destination Result

Move Medium Sense Keys

Read Element Status CDB Description

Read Element Status MC command B8h

18. Element Type Codes

17. Read Element Status Field Description

Read Element Status Data

19. Element Addresses

20. Block Structure of Read Element Status Data

21. Element Status Data Header

Element Status Data

22. Element Status Data Header Field Description

23. Element Status Page Header

Element Status

24. Element Status Page Header Field Description

25. Medium Transport Element Descriptor Type Code = 1h

Element Descriptors

26. Medium Transport Element Descriptor Field Description

28. Storage Element Descriptor Field Description

27. Storage Element Descriptor Type Code=2h

30. Import Export Element Descriptor Field Description

29. Import Export Element Descriptor Type Code=3h

31. Data Transfer Element Descriptor Type Code=4h

32. Data Transfer Element Descriptor Field Description

33. Allowed Source and Destination Elements

Source and Destination Elements

Read Element Status Sense Keys

34. Test Unit Ready Field Description

Test Unit Ready MC command 00h

Logical unit is not ready magazine is not present

35. Page Codes

Bits Mode Sense Default Bytes Values ACL Facl

37. Page Code 00 Device Unique Parameters Field Description

40. Operation of Cartridge Unload

38. Mode Codes

Code Mode Sense Mode Select

39. Eject Codes

P3P

41. Cartridge Map

Bytes Values

44. Facl Page Code 1Dh, Element Address Assignments

Bits Mode Sense Default Bytes Values

Reserved Code 9Eh Additional Page Length 02h Rotate 00h

StorMT 1b

49. Facl Page Code 1Fh, Device Capabilities

M2488 Product Guide Media Changer Commands IE → ST

DT → IE

DT → ST

Media Changer Commands M2488 Product Guide

51. VPD Page Format

50. Supported MC VPD Page Codes

53. Inquiry Data Format VPD Page 00h Supported VPD Pages

52. VPD Page Format Field Description

M2488 Product Guide Media Changer Commands

Implemented Operating Definition Page 81h

Ascii Operating Definition Description Data

Ascii Implemented Operating Definition Page 82h

56. Inquiry Data Format VPD Page C2h Product Identification

Product Identification Page C2h

M2488 Product Guide Tape Processing

Changing Mode Parameters

Changing Mode Parameters Permanent Error Handling

Chapter Tape Processing

Tape Processing M2488 Product Guide

Permanent Write Error

Permanent Error Handling

Tape Processing M2488 Product Guide

OZONExxxxyyyy text

Chapter Maintenance and Servicing

Operator Panel Displayed Error Messages

M2488 Product Guide Maintenance and Servicing

Nvram Initialization Required

Maintenance and Servicing M2488 Product Guide

Diagnostic Error Codes

4.1 Operator Panel Error Code Display

Mode RTN Test Title Loops Errors

Maintenance Terminal Error Code Display

Error Code 70 Sense Format on current command

Error Code Sense Format

Sense Data

Error Code 70 Sense Format Field Description

EOM ILI

Error Code 71 Sense Format deferred error reporting

Sksv

Error Code 71 Sense Format Field Description

FMT

Additional Sense Formats

Format 01h Sense Information, FMT

Sense Information Bytes

Format 0 Sense Information Description for SIC

Format 01h Sense Information for FMT

Additional Format Error Information Type

WTERR1 WTERR2

10. Format 01h Sense Information, Drive Field Description

Command Code

11. MTC to MTU Commands

12. Format 02h Sense Information, Scsi Hardware Registers

Format 2 and 3 Sense Information, Hardware Registers

24-27 SDDPHI.hdxc 28-31

13. Format 03h Sense Information, Edrc Hardware Registers

14. Format 04h Sense Information, Diagnostic Errors

Format 4 Sense Information for Diagnostic Errors

MTU Diagnostics

Diagnostics

1 Go/No-Go Diagnostics

Off-Line Diagnostics

OFF-LINE

16. Operator Panel Top Level Menus Diagnostics Mode

Cart ALL Stop ERR

Navigation keys

Setting Procedure

Command Selection Description Or Response

ERR

Operator Panel Off-Line Diagnostics

Bold

Command Description VARIABLES/ARGUMENTS

+/- ces

KEY

Commands

Valid Macro Names

Binary HEX Description

Types of Diagnostic Procedures

Tasked Go/No-Go Diagnostics

18. Options Byte Field Descriptions

19. Selftest Description

In-line Diagnostics

Test Description

Test Online Description Operator Routine Intervention

20. Page Code 80h Test Description

Parameter Limit

Diagnostic Test Registry

Diagnostic Microcode Specifications

21. Diagnostic Microcode Specifications

22. Operator Panel Top Level Menus Factory Option

Factory Settings

Option Settings Description Initial

23. Factory Menu Options and Settings Description

Edrc Error Recovery

Error Recovery Procedures

Retry Methods

M2488 Product Guide Maintenance and Servicing

Edrc Retry

Signal

Maintenance Terminal

Maintenance Interface

Signal Name Abbreviation Direction

Remote Debug for JDB

25. Maintenance Interface Communications Settings

Communications Setting Value

Procedure

Tape Path Cleaning Procedure

Preventive Maintenance

Step

Cartridge Tape Stopped During Loading

Manual Tape Removal Procedure

Gear

Tape Wound on Take-up Reel

Tape Stopped During Threading

Cable From Connector Description Type

Remove and Replace Procedures

M2488 Interconnects

DVL CNP21 DTC CNJ21

DVL CNP42

DVL CNJ43

DVL CNJ44

WTL CNP30 PSU CNP93

RDL CNJ12B

CNJ90B

RDL CNJ15 DVL CNJ22

Interconnect Diagram

FRUs Remove and Replace Procedures

Air Filter Replacement

Air Filter Remove and Replace Procedures

Air Filter Removal

Fan Assembly Replacement

Fan Assembly Remove and Replace Procedures

IPM Replacement

IPM Remove and Replace Procedures

IPM Removal

Top Cover Replacement

Top Cover Remove and Replace Procedures

Top Cover Removal

Bottom Cover Replacement

Bottom Cover Remove and Replace Procedures

Bottom Cover Removal

DTC Pcba Replacement

DTC Pcba Remove and Replace Procedures

DTC Pcba

Threader Assembly Removal

Threader Assembly Remove and Replace Procedures

Threader Assembly Replacement

Loader Assembly Removal

Loader Assembly Remove and Replace Procedures

Loader Assembly Replacement

OP PCA Replacement

OP PCA Remove and Replace Procedures

OP PCA Removal

Power Supply Removal

Power Supply PSU Remove and Replace Procedures

Power Supply Replacement

RDL Pcba Replacement

SVL Pcba Remove and Replace Procedures SVL Pcba Removal

SVL Pcba Replacement

RDL Pcba Remove and Replace Procedures RDL Pcba Removal

WTL

WTL Pcba Remove and Replace Procedures

WTL Pcba Replacement

WTL Pcba Removal

Maintenance and Servicing M2488 Product Guide

Field Replaceable Units

Chapter Parts Replacement Catalog

M2488 Product Guide Parts Replacement Catalog

Field Replaceable Units

M2488 Tape Drive FRUs Top Side

Parts Replacement Catalog M2488 Product Guide

M2488 Tape Drive FRUs Bottom Side

Scsi CNP07

CNJ06 CNJ04

CNP51 CNP55 CNP52

CNP54

WTL Pcba

Sense KEY Description

Appendix a Sense Keys

M2488 Product Guide Sense Keys

Table A-1. Sense Key Descriptions

Sense Keys M2488 Product Guide

Sense ASC/ASCQ Description Advised KEY Action

Appendix B ASC/ASCQ

M2488 Product Guide ASC/ASCQ

Table B-1. ASC and Ascq Description by Sense Key

Advised Action Code Description

ASC/ASCQ M2488 Product Guide

Table B-2. Action Advised Codes

ASC/ASCQ Description Advised KEY Action

Table B-3. ASC and Ascq Description by ASC/ASCQ

Table B-2 Action Advised Codes

Advised Description Action Code

Description KEY

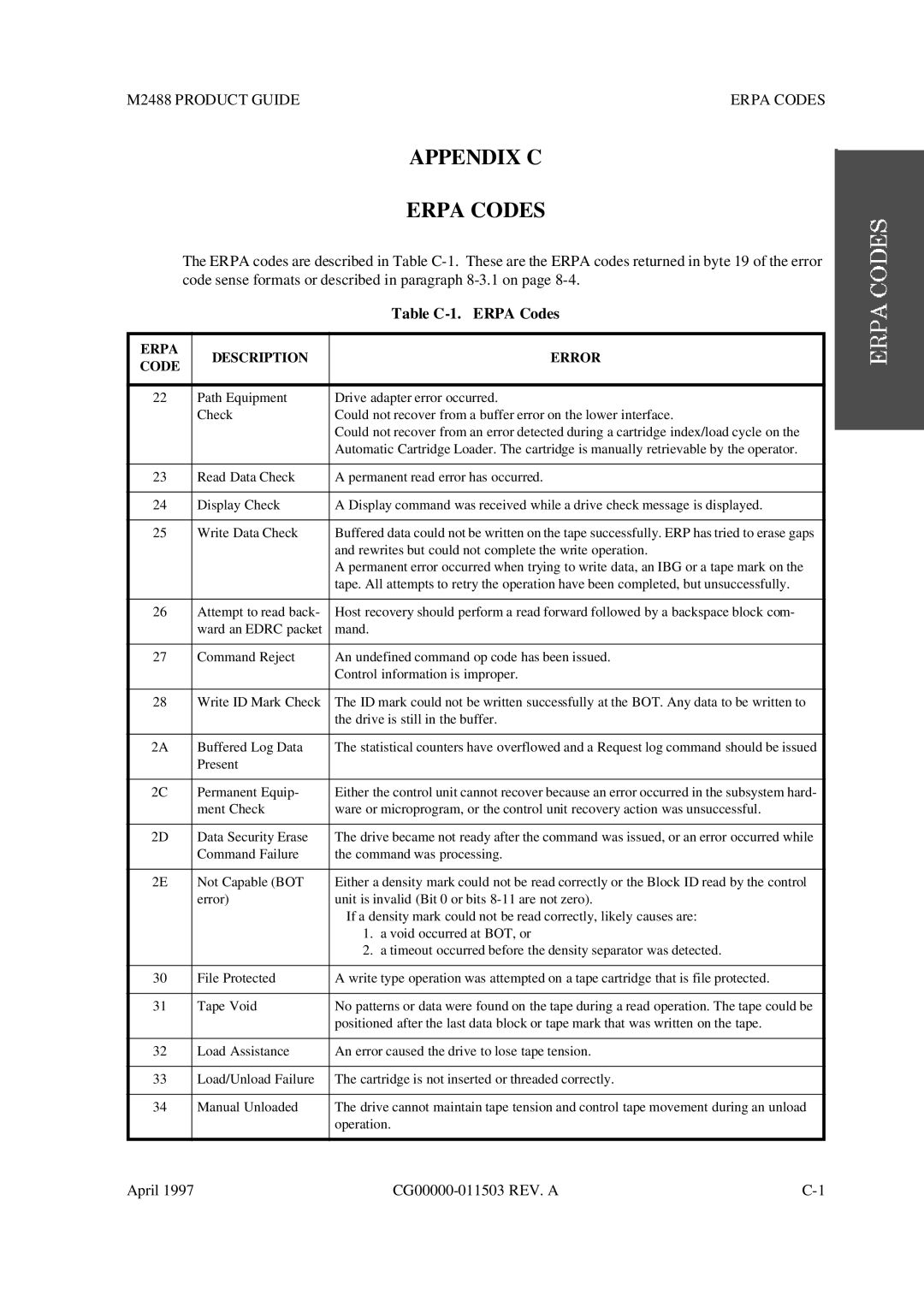

Table C-1. Erpa Codes

Erpa Description Error Code

Appendix C Erpa Codes

M2488 Product Guide Erpa Codes

Erpa Codes M2488 Product Guide

3CAE

Appendix D Fault Symptom Codes

M2488 Product Guide Fault Symptom Codes

Table D-1. Error Recovery

3CCB

Fault Symptom Codes M2488 Product Guide

Table D-2. Formatter Error Recovery

3CCA

Table D-2. Formatter Error Recovery

Table D-2. Formatter Error Recovery

Table D-2. Formatter Error Recovery

BC1D

Table E-1. CHK xx Error Code Descriptions

Appendix E CHK XX Error Codes

CHK XX Error Code Descriptions

M2488 Product Guide CHK XX Error Codes

Table E-1 CHK xx Error Code Descriptions

CHK XX Error Codes M2488 Product Guide

Table E-1 CHK xx Error Code Descriptions

Table E-1 CHK xx Error Code Descriptions

Table E-1 CHK xx Error Code Descriptions

Table E-1 CHK xx Error Code Descriptions

CHK Code Description

CHK XX Error Code Replacement Actions

Table E-2. CHK xx Error Code Replacement Actions

CHK Replacement Code Action

13, 15

Table E-2. CHK xx Error Code Replacement Actions

13, 14

Table E-2. CHK xx Error Code Replacement Actions

Table E-2. CHK xx Error Code Replacement Actions

Table E-3. Replacement Action Codes

PCA-DVL

M2488 Product Guide Diagnostic Tests and Error Codes

Appendix F Diagnostic Tests and Error Codes

Routine Test Diagnostic Modes Title

Diagnostic Tests and Error Codes M2488 Product Guide

Write EDRC-NC 3 bytes 00, mode 14h

Read Compression err/sgd crc-a errors

Read 4M tones test

Routine Test Title Error Description Code

Table F-2. Error Codes Common to all Routines/Tests

Table F-3. Routine 1 Control Store Diagnostic Error Codes

Diagnostic Tests and Error Codes

Table F-5. Routine 3 CP Bus Parity Diagnostic Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Table F-8. Routine 6 Data Buffer Diagnostic Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Table F-11. Routine 9 PCC Timers Diagnostic Error Codes

Diagnostic Tests and Error Codes

Sddp

~SCSIREQ, SCSIACK, Scsibsy

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

~SCSIREQ, SCSIACK, Scsibsy

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Sddp

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Dblk

Diagnostic Tests and Error Codes

Rsvp

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Dblk

Diagnostic Tests and Error Codes

Tected

Table F-17. Routine 50 4M Tones Test Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Table F-19. Routine 80 Servo Diagnostic Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes

Table F-25. Routine 90 Tape Drive Diagnostic Error Codes

Diagnostic Tests and Error Codes

Diagnostic Tests and Error Codes M2488 Product Guide

M2488 Product Guide Supported Scsi Transfer Rates

Appendix G Supported Scsi Transfer Rates

Table G-1. Scsi Transfer Rates for 20 MHz

Supported Scsi Transfer Rates M2488 Product Guide

M2488 Diag Structure

Appendix H MTU Diagnostic Specifications

HOW to Execute the Diag

Outline

ACL test

MTU Diagnostic Specifications M2488 Product Guide

READ/WRITE test

LOAD/UNLOAD test

Explanation

MTU Diag Parameter

Combination test

Diag activation parameter

Tape Path

Diag READ/WRITE Ten diagnostic tests to check read and write

Patha

Streaming

START/STOP

E. PT

Testmode Diagnostic test to measure operations

ACL Test Two diagnostic tests to check the autoloader

3.4.4 M4MODCH Mode change time measurement

3.4.3 M3AC/PS Measure the tape access/positioning time

3.4.1 M1LOAD Cartridge loading time measurement

3.4.7 M7D.S.E DSE time measurement

3.4.9 M9CLEAN Cleaning time measurement

3.4.5 M5LOCAT Tape locating time measurement

3.4.6 M6REWND Tape rewinding time measurement

Error reset command------- CMD CD 0x70 or 0xF0

Combination Running test by combining up to ten commands

Parameter List

MTU Diagnostic SPECIFICATIONSM2488 Product Guide

April CG00000-011503 REV. a

MTU Diagnostic Specifications M2488 Product Guide

M2488 Product Guide MTU Diagnostic Specifications

With Cartridge

No Cartridge

Name Code Diag command code

Diag parameter Specify a sector

M5LOCAT

Diag parameter Execute time Stop time Execute count Reserve

0x80 Diag parameter

END

Diag Result Data

MTU Diagnostic Specifications M2488 Product Guide

M2488 Product Guide MTU Diagnostic Specifications

MTU Diagnostic Specifications M2488 Product Guide

M2488 Product Guide Flowcharts

Appendix Flowcharts

Lowchart igureFPanelOperatorFI-1

M2488FLOWCHARTSPRODUCT Guide

MAG

RUN ACL

List Error

Flowcharts M2488 Product Guide

RUN CNT= ERR CNT=

FGUIDELOWCHARTSM2488 Product

REV Level

Code Upload Complete Power OFF

Insert Code Image Tape

Loading Ready Unloading Copying Image

10 Start

MED-CHGR

Wtrom Y

Fsgrp T

F6 Srnum F5 Ptime F4 Mtime

None

Fsgrp S

Index

Diagnostic

M2488 Product Guide Index

MTU

Diagnostic Specifications

Diagnostic Tests and Error Codes Diagnostics

Index M2488 Product Guide

Error Recovery

Error Messages

Inspection

Mode SELECT/MODE Sense Commands

Index M2488 Product Guide IPM Installation Instructions

Maintenance and Servicing Maintenance Terminal

Mode Select and Mode Sense Commands VPD

Scsi

Commands

Scsi BUS Status

Scsi Commands

Changing Mode Parameters

Index-8 CG00000-011503 REV. a April

M2488 Cartridge Tape Drive Product Guide

Comment Form

Page

M2488 Cartridge Tape Drive Product Guide

Page