MICROMASTER 440 Parameter List

RxD |

|

|

|

| Receive telegram |

|

| Receive |

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PZD |

|

|

|

|

|

| PKW |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PKW |

|

PZD | r2050 |

0 | [0] |

1[1]

2[2]

3 | [3] |

4[4]

5[5]

6[6]

7[7]

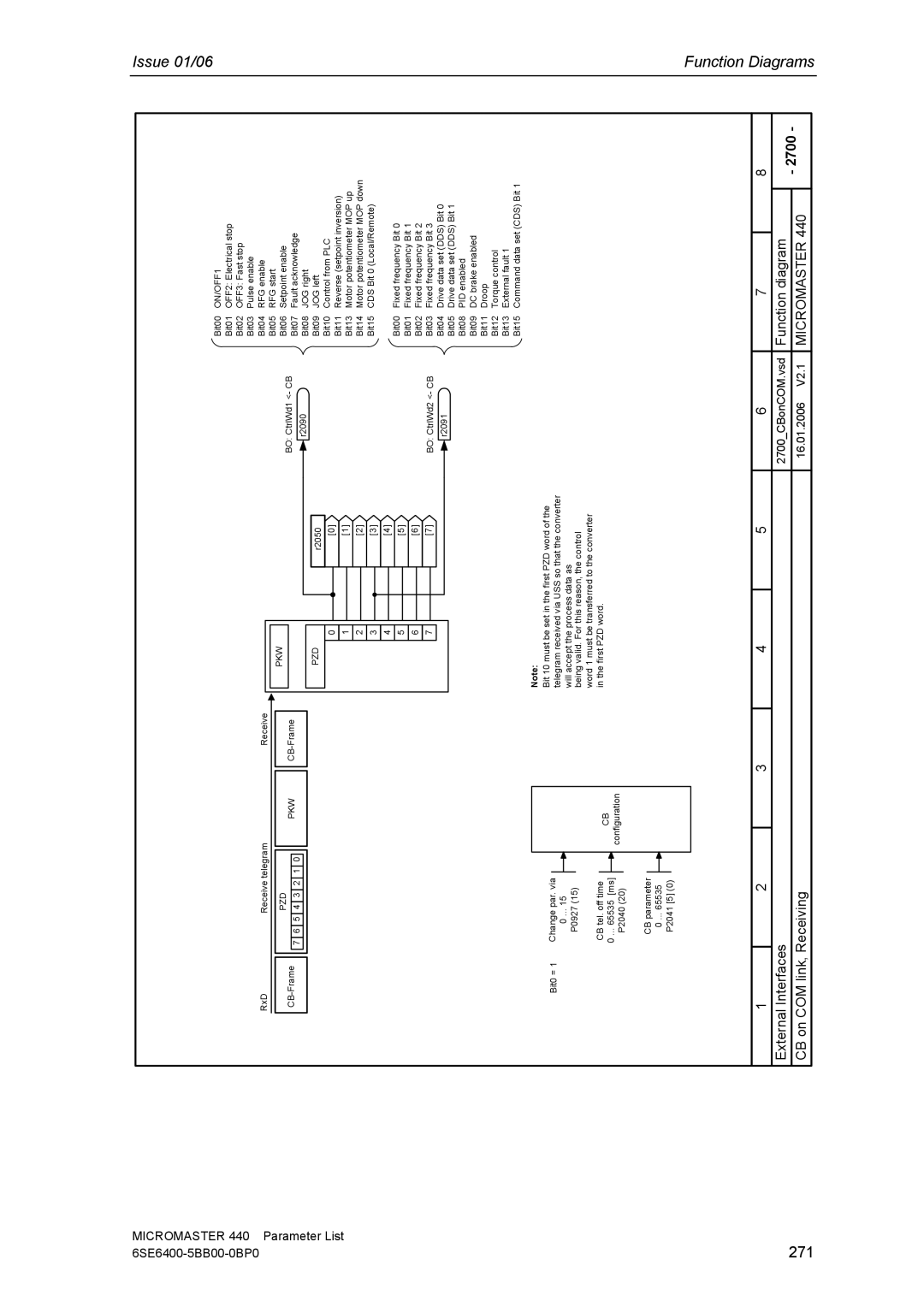

Note:

BO: CtrlWd1 <- CB ![]() r2090

r2090

BO: CtrlWd2 <- CB ![]() r2091

r2091

Bit00 | ON/OFF1 |

Bit01 | OFF2: Electrical stop |

Bit02 | OFF3: Fast stop |

Bit03 | Pulse enable |

Bit04 | RFG enable |

Bit05 | RFG start |

Bit06 | Setpoint enable |

Bit07 | Fault acknowledge |

Bit08 | JOG right |

Bit09 | JOG left |

Bit10 | Control from PLC |

Bit11 | Reverse (setpoint inversion) |

Bit13 | Motor potentiometer MOP up |

Bit14 | Motor potentiometer MOP down |

Bit15 | CDS Bit 0 (Local/Remote) |

Bit00 | Fixed frequency Bit 0 |

Bit01 | Fixed frequency Bit 1 |

Bit02 | Fixed frequency Bit 2 |

Bit03 | Fixed frequency Bit 3 |

Bit04 | Drive data set (DDS) Bit 0 |

Bit05 | Drive data set (DDS) Bit 1 |

Bit08 | PID enabled |

Bit09 | DC brake enabled |

Bit11 | Droop |

Bit12 | Torque control |

Bit13 | External fault 1 |

Bit15 | Command data set (CDS) Bit 1 |

Issue 01/06

Bit0 = 1 Change par. via 0 ... 15

P0927 (15)

CB tel. off time 0 ... 65535 [ms] P2040 (20)

CB parameter

0 ... 65535

P2041 [5] (0)

CB

configuration

Bit 10 must be set in the first PZD word of the telegram received via USS so that the converter

will accept the process data as

being valid. For this reason, the control word 1 must be transferred to the converter in the first PZD word.

271

1 |

| 2 | 3 | 4 | 5 | 6 | 7 |

| 8 |

External Interfaces |

|

|

|

|

| 2700_CBonCOM.vsd | Function diagram |

| - 2700 - |

CB on COM link, Receiving |

|

|

|

| 16.01.2006 V2.1 | MICROMASTER 440 | |||

|

|

|

|

| |||||