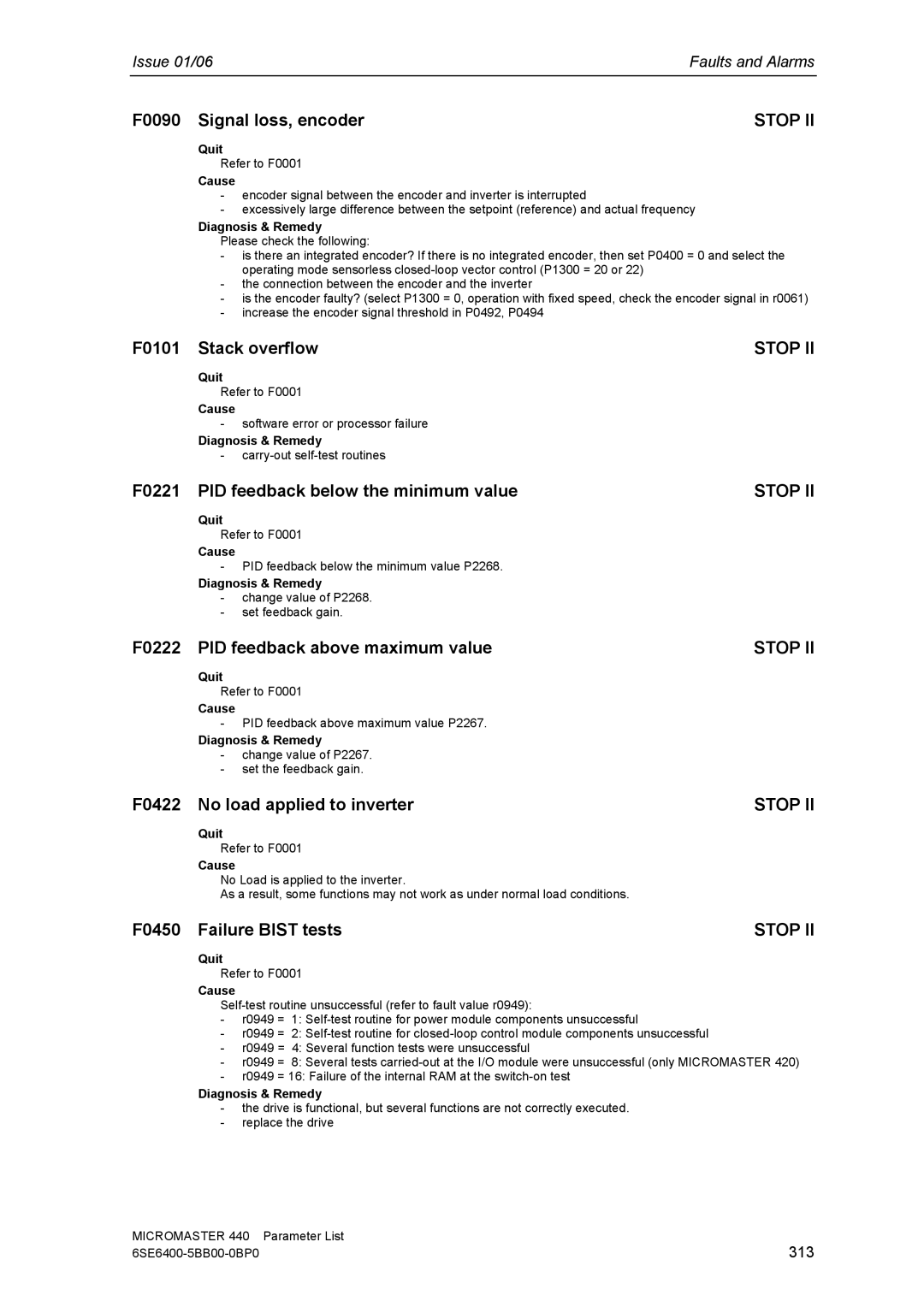

Issue 01/06 | Faults and Alarms |

F0090 Signal loss, encoder | STOP II |

Quit

Refer to F0001

Cause

-encoder signal between the encoder and inverter is interrupted

-excessively large difference between the setpoint (reference) and actual frequency

Diagnosis & Remedy

Please check the following:

-is there an integrated encoder? If there is no integrated encoder, then set P0400 = 0 and select the operating mode sensorless

-the connection between the encoder and the inverter

-is the encoder faulty? (select P1300 = 0, operation with fixed speed, check the encoder signal in r0061)

-increase the encoder signal threshold in P0492, P0494

F0101 Stack overflow | STOP II |

Quit

Refer to F0001

Cause

-software error or processor failure

Diagnosis & Remedy

-

F0221 PID feedback below the minimum value | STOP II |

Quit

Refer to F0001

Cause

-PID feedback below the minimum value P2268.

Diagnosis & Remedy

-change value of P2268.

-set feedback gain.

F0222 PID feedback above maximum value | STOP II |

Quit

Refer to F0001

Cause

-PID feedback above maximum value P2267.

Diagnosis & Remedy

-change value of P2267.

-set the feedback gain.

F0422 No load applied to inverter | STOP II |

Quit

Refer to F0001

Cause

No Load is applied to the inverter.

As a result, some functions may not work as under normal load conditions.

F0450 Failure BIST tests | STOP II |

Quit

Refer to F0001

Cause

-r0949 = 1:

-r0949 = 2:

-r0949 = 4: Several function tests were unsuccessful

-r0949 = 8: Several tests

-r0949 = 16: Failure of the internal RAM at the

Diagnosis & Remedy

-the drive is functional, but several functions are not correctly executed.

-replace the drive

MICROMASTER 440 | Parameter List |

313 |