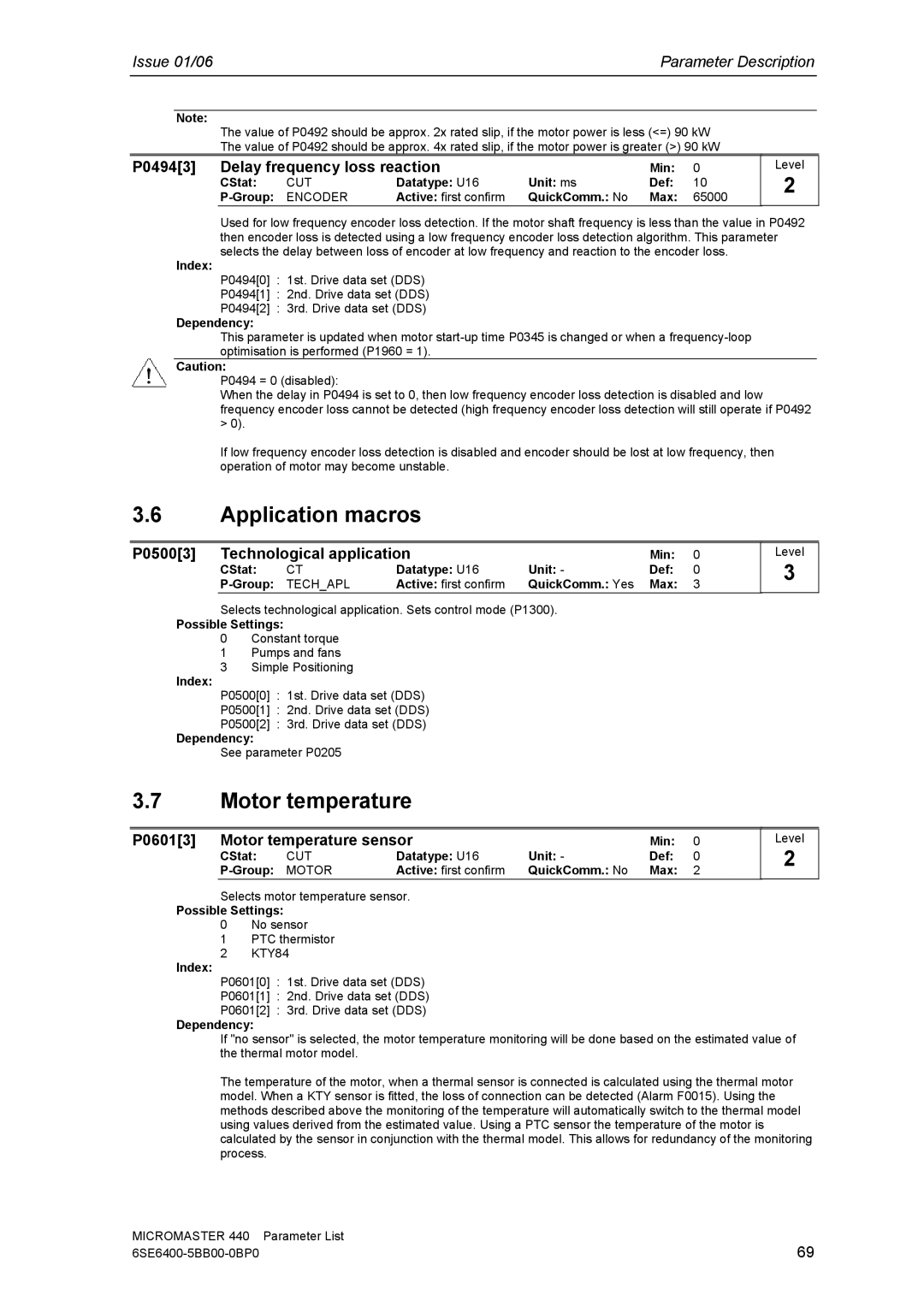

Issue 01/06 | Parameter Description |

Note:

The value of P0492 should be approx. 2x rated slip, if the motor power is less (<=) 90 kW

The value of P0492 should be approx. 4x rated slip, if the motor power is greater (>) 90 kW

P0494[3] Delay frequency loss reaction |

| Min: | 0 | ||

CStat: | CUT | Datatype: U16 | Unit: ms | Def: | 10 |

ENCODER | Active: first confirm | QuickComm.: No | Max: | 65000 | |

Level

2

Used for low frequency encoder loss detection. If the motor shaft frequency is less than the value in P0492 then encoder loss is detected using a low frequency encoder loss detection algorithm. This parameter selects the delay between loss of encoder at low frequency and reaction to the encoder loss.

Index:

P0494[0] : 1st. Drive data set (DDS)

P0494[1] : 2nd. Drive data set (DDS)

P0494[2] : 3rd. Drive data set (DDS)

Dependency:

This parameter is updated when motor

Caution:

P0494 = 0 (disabled):

When the delay in P0494 is set to 0, then low frequency encoder loss detection is disabled and low frequency encoder loss cannot be detected (high frequency encoder loss detection will still operate if P0492 > 0).

If low frequency encoder loss detection is disabled and encoder should be lost at low frequency, then operation of motor may become unstable.

3.6Application macros

P0500[3] | Technological application |

| Min: | 0 | ||

| CStat: | CT | Datatype: U16 | Unit: - | Def: | 0 |

| TECH_APL | Active: first confirm | QuickComm.: Yes | Max: | 3 | |

Selects technological application. Sets control mode (P1300).

Possible Settings:

0Constant torque

1Pumps and fans

3Simple Positioning

Index:

P0500[0] : 1st. Drive data set (DDS)

P0500[1] : 2nd. Drive data set (DDS)

P0500[2] : 3rd. Drive data set (DDS)

Dependency:

See parameter P0205

Level

3

3.7Motor temperature

P0601[3] Motor temperature sensor |

| Min: | 0 | ||

CStat: | CUT | Datatype: U16 | Unit: - | Def: | 0 |

MOTOR | Active: first confirm | QuickComm.: No | Max: | 2 | |

Selects motor temperature sensor.

Possible Settings:

0No sensor

1PTC thermistor

2KTY84

Index:

Level

2

P0601[0] : 1st. Drive data set (DDS)

P0601[1] : 2nd. Drive data set (DDS)

P0601[2] : 3rd. Drive data set (DDS)

Dependency:

If "no sensor" is selected, the motor temperature monitoring will be done based on the estimated value of the thermal motor model.

The temperature of the motor, when a thermal sensor is connected is calculated using the thermal motor model. When a KTY sensor is fitted, the loss of connection can be detected (Alarm F0015). Using the methods described above the monitoring of the temperature will automatically switch to the thermal model using values derived from the estimated value. Using a PTC sensor the temperature of the motor is calculated by the sensor in conjunction with the thermal model. This allows for redundancy of the monitoring process.

MICROMASTER 440 | Parameter List |

69 |