F416 |

| F423 | |||

|

|

|

| ||

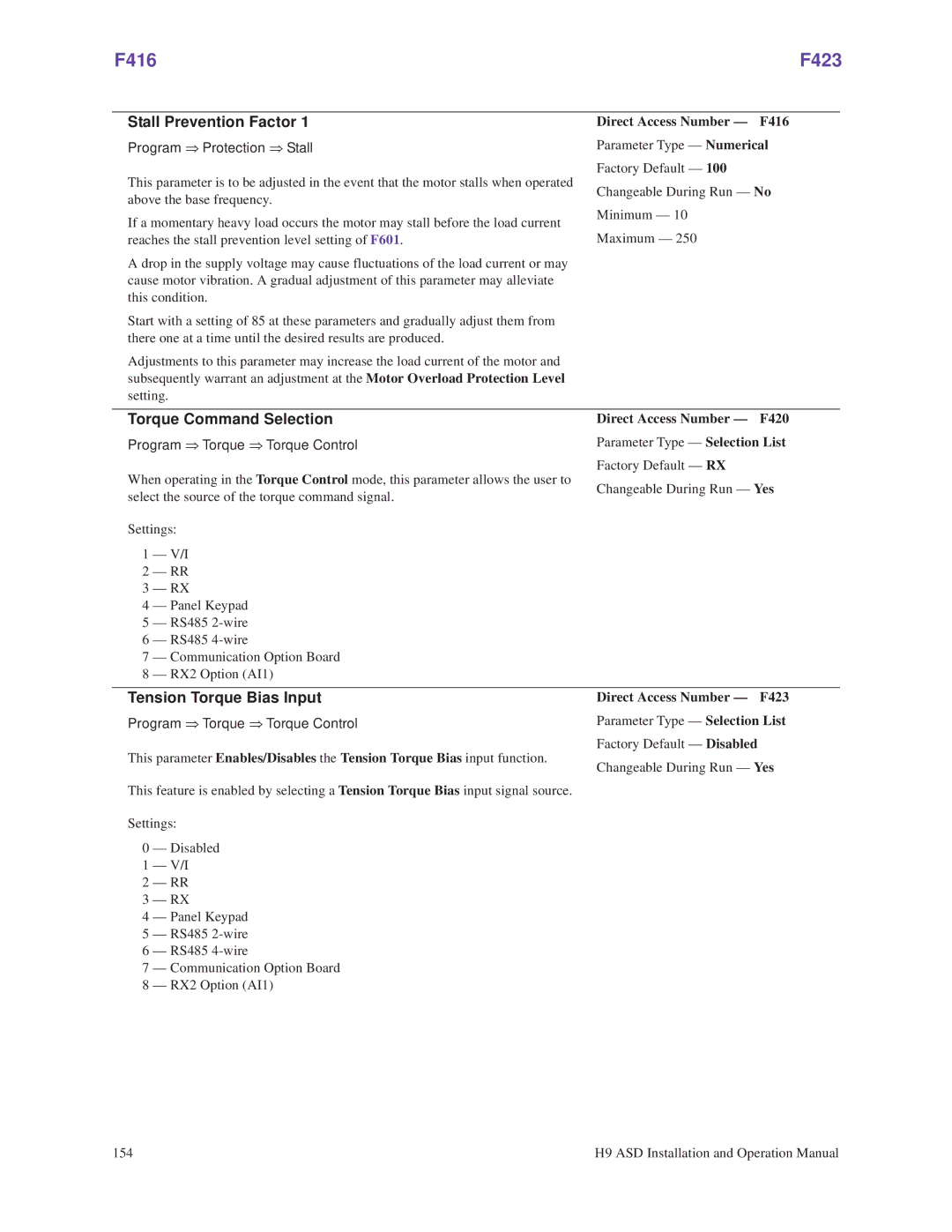

Stall Prevention Factor 1 | Direct Access Number — | F416 | |||

Program ⇒ Protection ⇒ Stall | Parameter Type — Numerical | ||||

This parameter is to be adjusted in the event that the motor stalls when operated | Factory Default — 100 |

|

| ||

Changeable During Run — No | |||||

above the base frequency. | |||||

|

|

| |||

If a momentary heavy load occurs the motor may stall before the load current | Minimum — 10 |

|

| ||

|

|

| |||

reaches the stall prevention level setting of F601. | Maximum — 250 |

|

| ||

A drop in the supply voltage may cause fluctuations of the load current or may |

|

|

| ||

cause motor vibration. A gradual adjustment of this parameter may alleviate |

|

|

| ||

this condition. |

|

|

| ||

Start with a setting of 85 at these parameters and gradually adjust them from |

|

|

| ||

there one at a time until the desired results are produced. |

|

|

| ||

Adjustments to this parameter may increase the load current of the motor and |

|

|

| ||

subsequently warrant an adjustment at the Motor Overload Protection Level |

|

|

| ||

setting. |

|

|

| ||

|

|

|

| ||

Torque Command Selection | Direct Access Number — | F420 | |||

Program ⇒ Torque ⇒ Torque Control | Parameter Type — Selection List | ||||

When operating in the Torque Control mode, this parameter allows the user to | Factory Default — RX |

|

| ||

Changeable During Run — Yes | |||||

select the source of the torque command signal. | |||||

|

|

| |||

Settings: |

|

|

| ||

1 | — V/I |

|

|

| |

2 | — RR |

|

|

| |

3 | — RX |

|

|

| |

4 | — Panel Keypad |

|

|

| |

5 | — RS485 |

|

|

| |

6 | — RS485 |

|

|

| |

7 | — Communication Option Board |

|

|

| |

8 | — RX2 Option (AI1) |

|

|

| |

|

|

|

| ||

Tension Torque Bias Input | Direct Access Number — | F423 | |||

Program ⇒ Torque ⇒ Torque Control | Parameter Type — Selection List | ||||

|

| Factory Default — Disabled |

|

| |

This parameter Enables/Disables the Tension Torque Bias input function.

Changeable During Run — Yes

This feature is enabled by selecting a Tension Torque Bias input signal source.

Settings:

0 — Disabled

1 — V/I

2 — RR

3 — RX

4 — Panel Keypad

5— RS485

6— RS485

7— Communication Option Board

8— RX2 Option (AI1)

154 | H9 ASD Installation and Operation Manual |