F318 |

| F322 | |

|

|

|

|

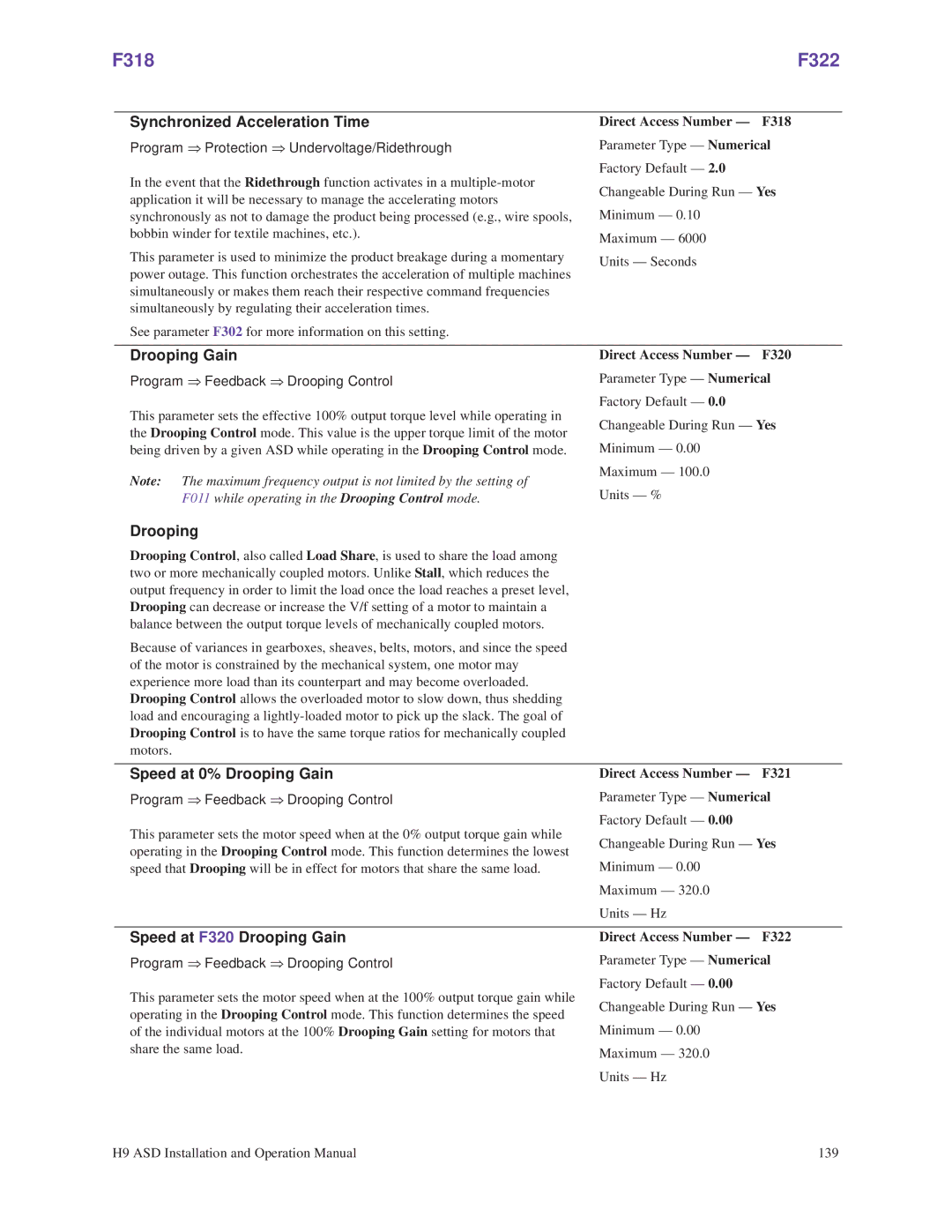

| Synchronized Acceleration Time | Direct Access Number — | F318 |

| Program ⇒ Protection ⇒ Undervoltage/Ridethrough | Parameter Type — Numerical | |

| In the event that the Ridethrough function activates in a | Factory Default — 2.0 |

|

| Changeable During Run — Yes | ||

| application it will be necessary to manage the accelerating motors | ||

|

|

| |

| synchronously as not to damage the product being processed (e.g., wire spools, | Minimum — 0.10 |

|

| bobbin winder for textile machines, etc.). | Maximum — 6000 |

|

|

|

| |

| This parameter is used to minimize the product breakage during a momentary | Units — Seconds |

|

| power outage. This function orchestrates the acceleration of multiple machines |

| |

|

|

| |

| simultaneously or makes them reach their respective command frequencies |

|

|

| simultaneously by regulating their acceleration times. |

|

|

| See parameter F302 for more information on this setting. |

|

|

|

|

|

|

| Drooping Gain | Direct Access Number — | F320 |

| Program ⇒ Feedback ⇒ Drooping Control | Parameter Type — Numerical | |

| This parameter sets the effective 100% output torque level while operating in | Factory Default — 0.0 |

|

| Changeable During Run — Yes | ||

| the Drooping Control mode. This value is the upper torque limit of the motor | ||

|

|

| |

| being driven by a given ASD while operating in the Drooping Control mode. | Minimum — 0.00 |

|

| Note: The maximum frequency output is not limited by the setting of | Maximum — 100.0 |

|

| Units — % |

| |

| F011 while operating in the Drooping Control mode. |

| |

| Drooping |

|

|

| Drooping Control, also called Load Share, is used to share the load among |

|

|

| two or more mechanically coupled motors. Unlike Stall, which reduces the |

|

|

| output frequency in order to limit the load once the load reaches a preset level, |

|

|

| Drooping can decrease or increase the V/f setting of a motor to maintain a |

|

|

| balance between the output torque levels of mechanically coupled motors. |

|

|

| Because of variances in gearboxes, sheaves, belts, motors, and since the speed |

|

|

| of the motor is constrained by the mechanical system, one motor may |

|

|

| experience more load than its counterpart and may become overloaded. |

|

|

| Drooping Control allows the overloaded motor to slow down, thus shedding |

|

|

| load and encouraging a |

|

|

| Drooping Control is to have the same torque ratios for mechanically coupled |

|

|

| motors. |

|

|

|

|

|

|

| Speed at 0% Drooping Gain | Direct Access Number — | F321 |

| Program ⇒ Feedback ⇒ Drooping Control | Parameter Type — Numerical | |

| This parameter sets the motor speed when at the 0% output torque gain while | Factory Default — 0.00 |

|

| Changeable During Run — Yes | ||

| operating in the Drooping Control mode. This function determines the lowest | ||

|

|

| |

| speed that Drooping will be in effect for motors that share the same load. | Minimum — 0.00 |

|

Maximum — 320.0

Units — Hz

Speed at F320 Drooping Gain

Program ⇒ Feedback ⇒ Drooping Control

This parameter sets the motor speed when at the 100% output torque gain while operating in the Drooping Control mode. This function determines the speed of the individual motors at the 100% Drooping Gain setting for motors that share the same load.

Direct Access Number — F322

Parameter Type — Numerical

Factory Default — 0.00

Changeable During Run — Yes

Minimum — 0.00

Maximum — 320.0

Units — Hz

H9 ASD Installation and Operation Manual | 139 |