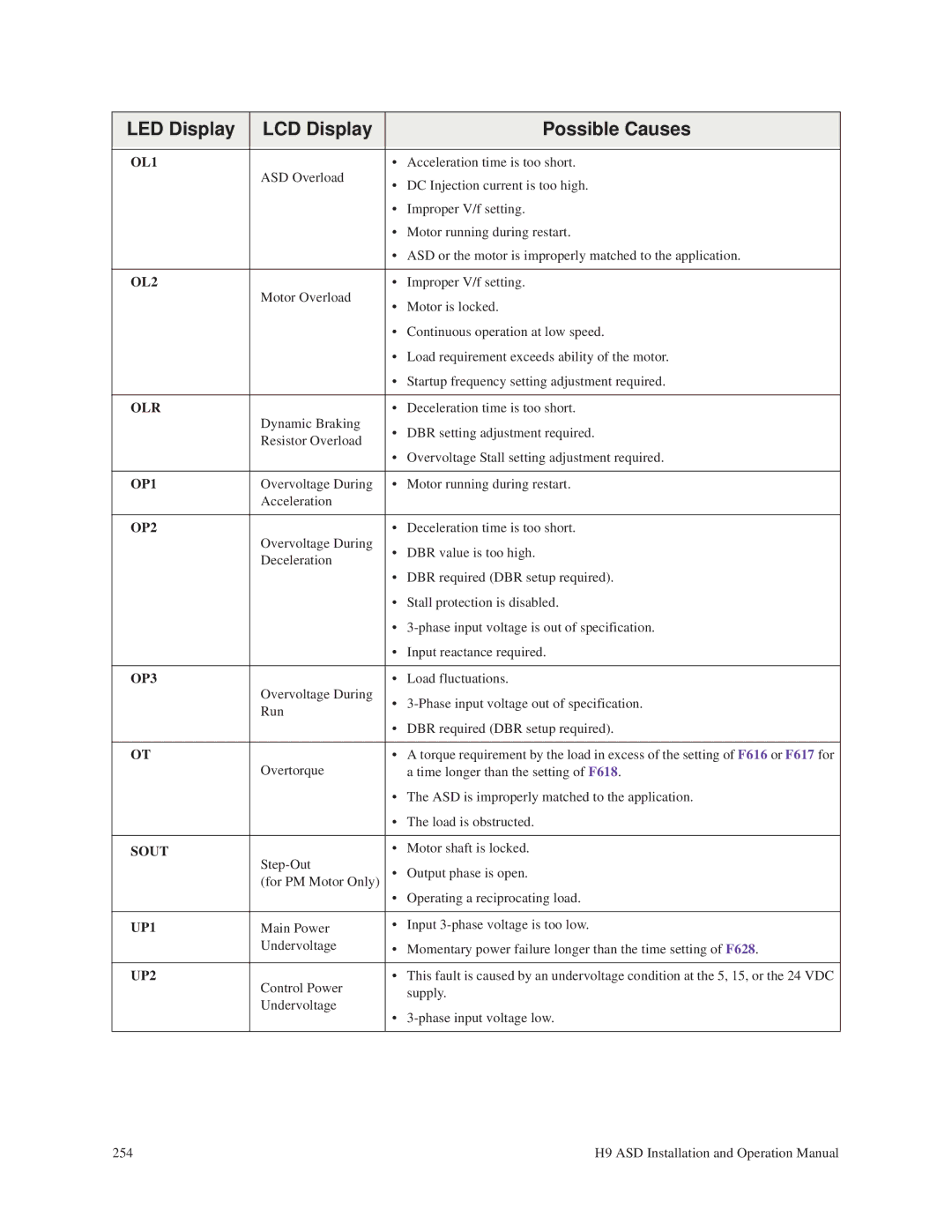

LED Display | LCD Display |

| Possible Causes |

|

|

|

|

|

|

|

|

OL1 |

| • | Acceleration time is too short. |

| ASD Overload | • DC Injection current is too high. | |

|

| ||

|

| • | Improper V/f setting. |

|

| • Motor running during restart. | |

|

| • ASD or the motor is improperly matched to the application. | |

|

|

|

|

OL2 |

| • | Improper V/f setting. |

| Motor Overload | • | Motor is locked. |

|

| ||

|

| • Continuous operation at low speed. | |

|

| • Load requirement exceeds ability of the motor. | |

|

| • Startup frequency setting adjustment required. | |

|

|

|

|

OLR |

| • | Deceleration time is too short. |

| Dynamic Braking | • DBR setting adjustment required. | |

| Resistor Overload | ||

|

|

| |

|

| • Overvoltage Stall setting adjustment required. | |

|

|

|

|

OP1 | Overvoltage During | • | Motor running during restart. |

| Acceleration |

|

|

|

|

|

|

OP2 |

| • | Deceleration time is too short. |

| Overvoltage During | • DBR value is too high. | |

| Deceleration | ||

|

|

| |

|

| • DBR required (DBR setup required). | |

|

| • Stall protection is disabled. | |

|

| • | |

|

| • | Input reactance required. |

|

|

|

|

OP3 |

| • | Load fluctuations. |

| Overvoltage During | • | |

| Run | ||

|

|

| |

|

| • DBR required (DBR setup required). | |

|

|

|

|

OT |

| • | A torque requirement by the load in excess of the setting of F616 or F617 for |

| Overtorque |

| a time longer than the setting of F618. |

|

| • The ASD is improperly matched to the application. | |

|

| • The load is obstructed. | |

|

|

|

|

SOUT | • | Motor shaft is locked. | |

| • | Output phase is open. | |

| (for PM Motor Only) | ||

|

| • Operating a reciprocating load. | |

|

|

|

|

UP1 | Main Power | • | Input |

| Undervoltage | • | Momentary power failure longer than the time setting of F628. |

|

|

|

|

UP2 | Control Power | • | This fault is caused by an undervoltage condition at the 5, 15, or the 24 VDC |

|

| supply. | |

| Undervoltage |

| |

| • | ||

|

| ||

|

|

|

|

254 | H9 ASD Installation and Operation Manual |