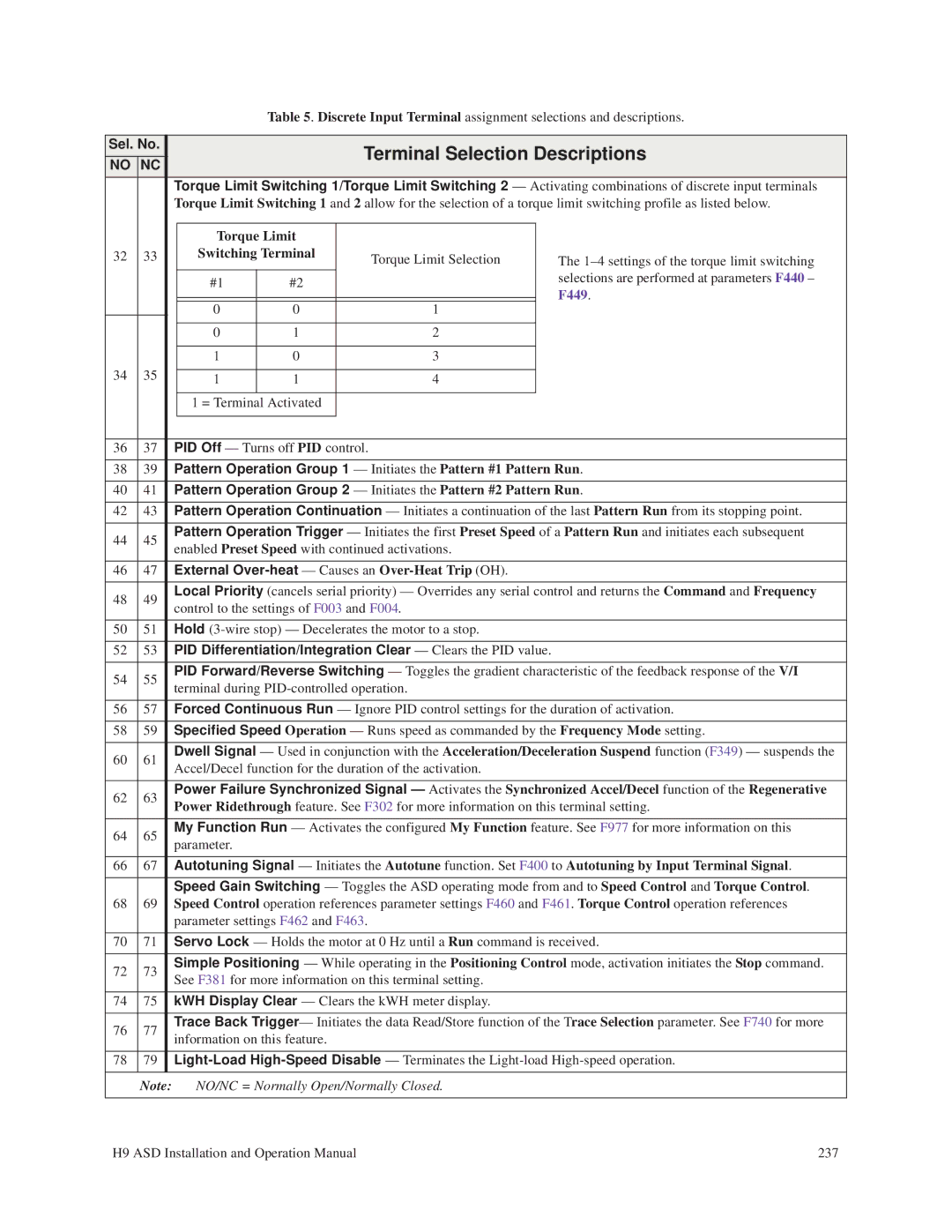

Table 5. Discrete Input Terminal assignment selections and descriptions.

Sel. No. |

|

|

|

| Terminal Selection Descriptions | ||||

NO | NC |

|

|

|

| ||||

|

|

|

|

|

|

|

| ||

|

|

| Torque Limit Switching 1/Torque Limit Switching 2 — Activating combinations of discrete input terminals | ||||||

|

|

| Torque Limit Switching 1 and 2 allow for the selection of a torque limit switching profile as listed below. | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Torque Limit |

|

|

|

| |

32 | 33 |

|

| Switching Terminal |

| Torque Limit Selection |

| The | |

|

|

|

| #1 | #2 |

|

|

| selections are performed at parameters F440 – |

|

|

|

|

|

|

| F449. | ||

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

| 0 | 0 |

| 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0 | 1 |

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 | 0 |

| 3 |

|

|

34 | 35 |

|

|

|

|

|

|

|

|

|

| 1 | 1 |

| 4 |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 = Terminal Activated |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36 | 37 |

| PID Off — Turns off PID control. |

|

|

| |||

|

|

|

|

|

|

|

| ||

38 | 39 |

| Pattern Operation Group 1 — Initiates the Pattern #1 Pattern Run. | ||||||

|

|

|

|

|

|

|

| ||

40 | 41 |

| Pattern Operation Group 2 — Initiates the Pattern #2 Pattern Run. | ||||||

|

|

|

|

|

|

|

| ||

42 | 43 |

| Pattern Operation Continuation — Initiates a continuation of the last Pattern Run from its stopping point. | ||||||

|

|

|

|

|

|

|

| ||

44 | 45 |

| Pattern Operation Trigger — Initiates the first Preset Speed of a Pattern Run and initiates each subsequent | ||||||

| enabled Preset Speed with continued activations. |

| |||||||

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| |

46 | 47 |

| External |

| |||||

|

|

|

|

|

|

|

| ||

48 | 49 |

| Local Priority (cancels serial priority) — Overrides any serial control and returns the Command and Frequency | ||||||

| control to the settings of F003 and F004. |

| |||||||

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| |

50 | 51 |

| Hold |

| |||||

|

|

|

|

|

|

|

|

| |

52 | 53 |

| PID Differentiation/Integration Clear — Clears the PID value. |

| |||||

|

|

|

|

|

|

|

| ||

54 | 55 |

| PID Forward/Reverse Switching — Toggles the gradient characteristic of the feedback response of the V/I | ||||||

| terminal during |

| |||||||

|

|

|

| ||||||

|

|

|

|

|

|

|

| ||

56 | 57 |

| Forced Continuous Run — Ignore PID control settings for the duration of activation. | ||||||

|

|

|

|

|

|

|

| ||

58 | 59 |

| Specified Speed Operation — Runs speed as commanded by the Frequency Mode setting. | ||||||

|

|

|

|

|

|

|

| ||

60 | 61 |

| Dwell Signal — Used in conjunction with the Acceleration/Deceleration Suspend function (F349) — suspends the | ||||||

| Accel/Decel function for the duration of the activation. |

| |||||||

|

|

|

| ||||||

|

|

|

|

|

|

|

| ||

62 | 63 |

| Power Failure Synchronized Signal — Activates the Synchronized Accel/Decel function of the Regenerative | ||||||

| Power Ridethrough feature. See F302 for more information on this terminal setting. | ||||||||

|

|

| |||||||

|

|

|

|

|

|

|

| ||

64 | 65 |

| My Function Run — Activates the configured My Function feature. See F977 for more information on this | ||||||

| parameter. |

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

66 | 67 |

| Autotuning Signal — Initiates the Autotune function. Set F400 to Autotuning by Input Terminal Signal. | ||||||

|

|

|

|

|

|

|

| ||

|

|

| Speed Gain Switching — Toggles the ASD operating mode from and to Speed Control and Torque Control. | ||||||

68 | 69 |

| Speed Control operation references parameter settings F460 and F461. Torque Control operation references | ||||||

|

|

| parameter settings F462 and F463. |

|

|

| |||

|

|

|

|

|

|

|

| ||

70 | 71 |

| Servo Lock — Holds the motor at 0 Hz until a Run command is received. | ||||||

|

|

|

|

|

|

|

| ||

72 | 73 |

| Simple Positioning — While operating in the Positioning Control mode, activation initiates the Stop command. | ||||||

| See F381 for more information on this terminal setting. |

| |||||||

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| |

74 | 75 |

| kWH Display Clear — Clears the kWH meter display. |

| |||||

|

|

|

|

|

|

|

| ||

76 | 77 |

| Trace Back Trigger— Initiates the data Read/Store function of the Trace Selection parameter. See F740 for more | ||||||

| information on this feature. |

|

|

| |||||

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||

78 | 79 |

| |||||||

|

|

|

|

|

|

|

|

| |

| Note: |

| NO/NC = Normally Open/Normally Closed. |

| |||||

|

|

|

|

|

|

|

|

|

|

H9 ASD Installation and Operation Manual | 237 |