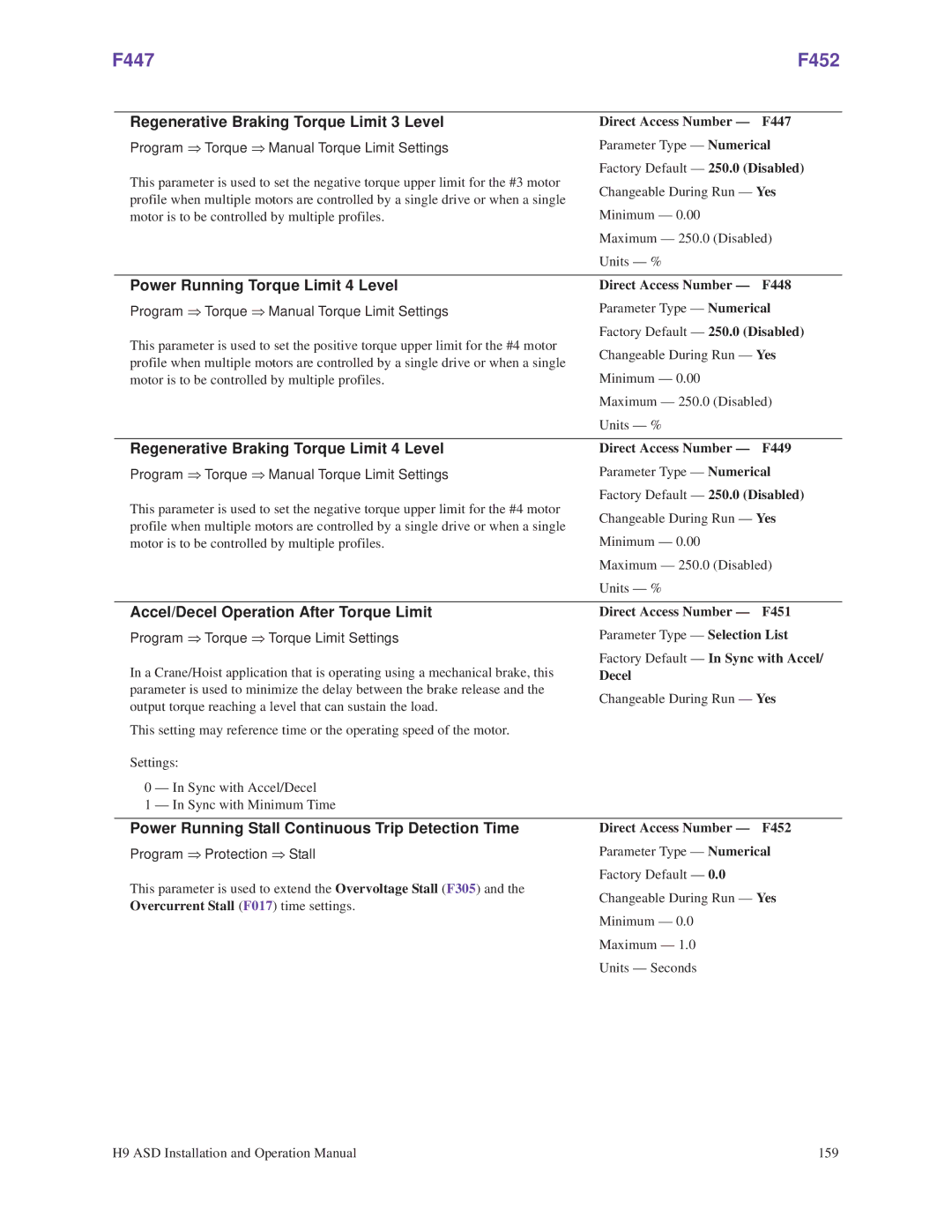

Regenerative Braking Torque Limit 3 Level

Program ⇒ Torque ⇒ Manual Torque Limit Settings

This parameter is used to set the negative torque upper limit for the #3 motor profile when multiple motors are controlled by a single drive or when a single motor is to be controlled by multiple profiles.

Direct Access Number — F447

Parameter Type — Numerical

Factory Default — 250.0 (Disabled)

Changeable During Run — Yes

Minimum — 0.00

Maximum — 250.0 (Disabled) Units — %

Power Running Torque Limit 4 Level

Program ⇒ Torque ⇒ Manual Torque Limit Settings

This parameter is used to set the positive torque upper limit for the #4 motor profile when multiple motors are controlled by a single drive or when a single motor is to be controlled by multiple profiles.

Direct Access Number — F448

Parameter Type — Numerical

Factory Default — 250.0 (Disabled)

Changeable During Run — Yes

Minimum — 0.00

Maximum — 250.0 (Disabled) Units — %

Regenerative Braking Torque Limit 4 Level

Program ⇒ Torque ⇒ Manual Torque Limit Settings

This parameter is used to set the negative torque upper limit for the #4 motor profile when multiple motors are controlled by a single drive or when a single motor is to be controlled by multiple profiles.

Direct Access Number — F449

Parameter Type — Numerical

Factory Default — 250.0 (Disabled)

Changeable During Run — Yes

Minimum — 0.00

Maximum — 250.0 (Disabled) Units — %

Accel/Decel Operation After Torque Limit | Direct Access Number — | F451 | |

Program ⇒ Torque ⇒ Torque Limit Settings | Parameter Type — Selection List | ||

In a Crane/Hoist application that is operating using a mechanical brake, this | Factory Default — In Sync with Accel/ | ||

Decel |

| ||

parameter is used to minimize the delay between the brake release and the | Changeable During Run — Yes | ||

output torque reaching a level that can sustain the load. | |||

|

| ||

This setting may reference time or the operating speed of the motor. |

|

| |

Settings: |

|

| |

0 — In Sync with Accel/Decel |

|

| |

1 — In Sync with Minimum Time |

|

| |

|

|

| |

Power Running Stall Continuous Trip Detection Time | Direct Access Number — | F452 | |

Program ⇒ Protection ⇒ Stall | Parameter Type — Numerical | ||

| Factory Default — 0.0 |

| |

This parameter is used to extend the Overvoltage Stall (F305) and the

Overcurrent Stall (F017) time settings.

Changeable During Run — Yes

Minimum — 0.0

Maximum — 1.0

Units — Seconds

H9 ASD Installation and Operation Manual | 159 |