Sysmac CQM1H Series

Serial Communications Board

Omron Product References

Omron

Name Cat. No Contents

About this Manual

Table of Contents

Communications for 11 Data Links 107

Precautions

Safety Precautions

General Precautions

Intended Audience

Operating Environment Precautions

Application Precautions

Xiv

Concepts

Conformance to EC Directives

Applicable Directives

Conformance to EC Directives

Recommended Ferrite Cores

Recommended Mounting Method

Section

Model Number

Features

Overview

Serial Communications Boards

System Configuration

Protocol Overview

Mounting Location

Protocol Macros

Host Link Mode

Sending C-mode Host Link Commands

Slave-initiated Communications

No-protocol Communications

4 PC 11 Data Links

NT Links -- 1N Mode

NT Links -- 11 Mode

General Specifications

Specifications

Basic Operating Procedure

Serial Communications Board

Board Components and Installation

Indicator Color Status Meaning

Indicators

Board Indicators

Component Names and Functions

Connector Pin Layout

CPU Unit Indicators

2 RS-232C Port

3 RS-422A/485 Port

Applicable Connectors

Tions method Wire Wire, 1N Synchroniza

Recommended Cables

Terminating Resistance Switch Wire or 4-Wire Switch

Switches

Label Name Settings Factory setting

Installation

Mounting the Board

External Dimensions

Mounting Height and Connector Cover Dimensions

Precautions in Handling the Board

Standard Connectors For Both RS-232C RS-422A/485

Wiring

Connectors

Recommended Cables RS-232C Cables

Reducing Electrical Noise for External Wiring

Wiring Precautions

RS-422A/485 Cable

WiringSection

Recommended RS-232C Wiring Examples

Pin Function Factory Setting

Recommended RS-422A/485 Cable

Recommended RS-422A/485 Wiring Examples

Wire Connections

Model Manufacturer CO-HC-ESV-3Px7/0.2 Hirakawa Hewtech Corp

Using an NT-AL001-E RS-232C/RS-422 Link Adapter

Using a 3G2A9-AL001 Link Adapter

Length Model

Cable Preparation

Wiring Connectors

Shield Connected to Hood FG

Shield Not Connected to Hood FG

Assembling Connector Hood

Soldering

Connecting to the Board

Default Settings and Related Bits/Flags

PC Setup Settings

Contents Addresses

Words Bits Function Applicable Mode

Control Bits, Flags, and Status Information

Word Bits Function Communications Modes

00 to Port

Word Bits Function Inner Board Error Flag

Slot 1 Inner Board Error Code Hex

Host Link Communications

Host Link Communications

TXD-- Instruction

Host Link Communications

Serial communications Features Mode

Simultaneous Usage of Both Ports

Application Procedure

Host Link Specifications

Port Bits Default Function Setting

Host-initiated Communications Host Link Commands

PC-initiated Communications TXD-- Instruction

Types of Connection

Port Configura Schematic diagram Tion RS-232C

Connections

Connection Examples

Using NT-AL001-E Converting Link Adapters

RTS RS-232C

1N Connections Using RS-232C Ports

Connections Using RS-422A/485 Ports

1N Connections Using RS-422A/485 Ports

Preparing an RS-232C Cable for the Computer

Standard Cables from Board to Personal Computer

Board port Computer Network type Model Length Remarks Port

Normal Response Frame

Protocol

Format

Error Response Frame Format

FCS Frame Check Sequence

Communications Sequence

Computer

Example Programs

Using the TXD-- Instruction

Example Program for

Communications Control Signals Communications Timing

TXD-- Application Example

Setting a Transmission Delay

Host Link Commands

Header code PC mode Name

End Contents Probable cause Corrective measures Code

End Codes

Changes from Previous Products

RS-232C Ports

Half-duplex transmissions that use CD

Full-duplex transmissions that do not use

2 RS-422A/485 Ports

Protocol Macros

Overview of the Protocol Macro Functions

Protocol Macro Function Specifications

Control

Sequence contents Number of steps

Step common Per sequence Parameters Transmission

Parameters Response

Repeat counter

Step contents Commands

Error processing

Retry count

Data attrib Stant

Description Message con Con

Tents Header Stant Terminator Data attrib Utes Con

Utes of ad Vari

Using the Standard System Protocols

Using the Protocol Macro Function

Be traced

Modifying Standard System Protocols

SEND&RECEIVE

Restriction Procedure

Restrictions in Using the CX-Protocol

Storage Memory

Select Transfer to PLC via Online or

Using Standard System Protocols

Port Bits Setting Function

Send Data

Using User-created Protocols

Receive Data

Transferring the created project to the Board

Port Configuration Schematic diagram

Connecting RS-232C Ports Connections to E5CK Controller

Connections to a Modem

DIP SW

485 RS-422A Terface Hood

3G2A9-AL001

Protocol Structure

Receive

Sequence Parameters

Parameter Meaning

Level Setting

Step Parameters

Level Possible changes in settings

Port 2 Protocol Macro Execution Error Flag

Board Identification Error Flag hardware error

Protocol Data Error Flag

Port 1 Protocol Macro Execution Error Flag

Port 2 Communications Error Flag

Word Bits Name and Function Classifi Set Reset Cation

Port 1 Communications Error Flag

Port 1 Sequence Abort Completion Flag

Port 2 Tracing Flag

Port 1 Protocol Macro Error Code

Port 2 Protocol Macro Error Code

Port 1 Executed Reception Case No. code

Port 2 Continuous Trace Start/Stop Bit

Port 2 Restart Bit

Port 1 Continuous Trace Start/Stop Bit

Port 1 Shot Trace Start/Stop Bit

Port 1 Sequence END Completion Flag

Port 1 Transfer Step Error Processing Flag

Port 2 Transfer Step Error Processing Flag

Port 1 Forced Abort Bit

Error Codes

Using Protocol Macros

PMCR-- Instruction Specifications

Executing Communications Sequences

Storage Word D

Flags

First Receive Data

PMCR-- Operation

Operand Areas and Address Ranges

Ladder Program Structure

Programming Example

Send Word Allocation for Sequence No Present Value Read

Ladder Program Example

Connections

Receive Word Allocation for Sequence No Present Value Read

Operand Settings for the PMCR-- Instruction

Precaution on Reception Failures for Pmcr

Ladder Programming Example

Transmission Methods

Time Lag t1

Error Flags for Overrun, Framing, and Parity Errors

Baud rate b/s Lag time ms

Processing When a Sequence Ends Abnormally

Example

Precautions on Using the Force Abort Bit

No-protocol Communications

No-protocol Specifications

Specification

Send/Receive Message Frames

Start code End code Yes

100

Connecting to a Bar Code Reader via RS-232C

Transmit TXD-- and Receive RXD

Using No-protocol Communications

Transmit TXD-- in No-protocol Mode

Control Word C

Receive RXD-- in No-protocol Mode

TXD-- Communications Procedure

RXD-- Communications Procedure

Application Example

PC Settings

Computer Settings

Conditions

Communications for 11 Data Links

Starting Data Links

PC Setup Setting

Port Bits Function Setting

OverviewSection

Specifications

Overview

Slave PC Settings

Using 11 Data Links

Master PC Settings

Conditions

NT Link Communications

Precautions

NT Links 1N Mode

NT Links 11 Mode

Overview of NT Links

115

NT Link Settings for 1N Mode

NT Link Settings for 11 Mode

117

118

Troubleshooting and Maintenance

Front-panel Indicator Error Displays

Indicators Possible cause Remedy Board CPU Unit

Board Error Information

Troubleshooting

Serial Communications

122

123

124

Board ReplacementSection

126

Error Indicator Error details Cause Remedy Code

Not perform

128

3 1N NT Link Mode

Cleaning and Inspection

Cleaning

Materials Required Occasionally

Inspection

Materials Required Daily

Inspection Items

Settings after Replacing the Board

Board Replacement

Replacement Procedure

Protocol Macros Designed with CX-Protocol

Introduction

Using Standard System Protocols

Procedure

Example

Receive Data Word Allocation 4th Operand

Standard System Protocols

Protocol name Function

CompoWay/F Master Protocol

System Configuration for Standard System Protocol

CompoWay/F

Command and Response Formats

Communications Specifications

Transmission Procedure

Command Format

Response Frame Contents

Command Frame Contents

Appendix B

Example

Command Frame

Command Data contents Code

End code Name Meaning

Example Variable Area Read

Command and Text

Variable type Contents

Response Text

CompoWay/F Master Protocol Sequences

Structure of the Protocol

Send with Ascii Conversion, with Response Sequence No

CompoWay/F Message Frames and PMCR260 Operands

Response Frame

Send Data Word Allocation 2nd Operand of PMCR260

Receive Data Word Allocation 3rd Operand of PMCR260

145

Broadcast with Ascii Conversion, No Response Sequence No

Send with No Conversion and with Response Sequence No

Broadcast with No Conversion and No Response Sequence No

149

150

Connections

RS-232C

RS-422 4-wire Connections

RS-485 2-wire Connections

Appendix C

E5jK Digital Controller Read Protocol

RS-232C Connection

Connection Configuration

RS-485 Connection

Appendix C

Read Process Value Sequence No

Read Set Point during SP Ramp Sequence No

Send Data Word Allocation 2nd Operand of Pmcr

Read MV Sequence No

Read Alarm Value Sequence No

Read Set Point Sequence No

Read Cooling Coefficient Sequence No

Read Manual Reset Value Sequence No

Read Dead Band Sequence No

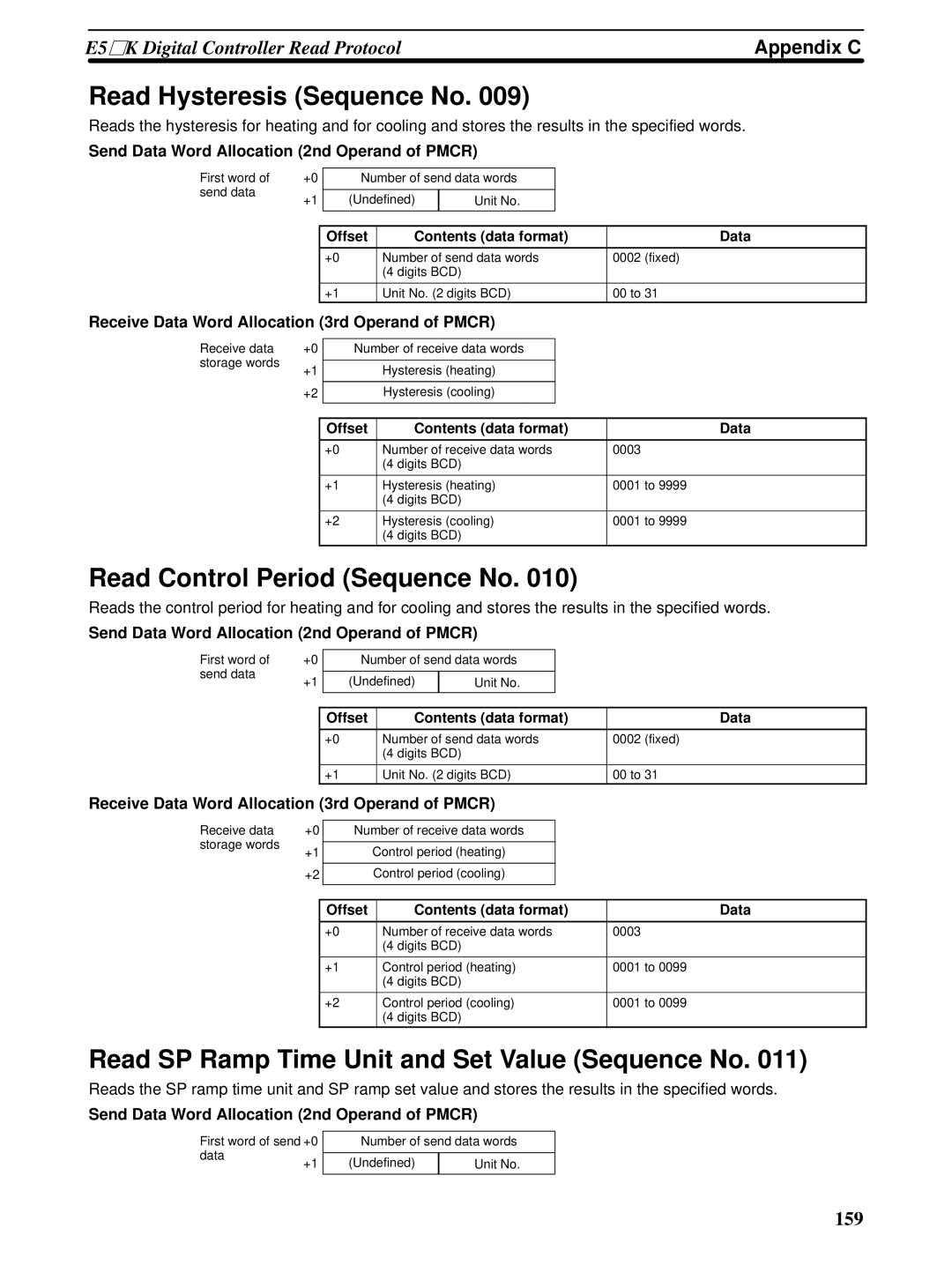

Read Control Period Sequence No

Read Hysteresis Sequence No

Read SP Ramp Time Unit and Set Value Sequence No

Read LBA Detection Time Sequence No

Read MV at Stop Time and at PV Error Sequence No.013

Read MV Limits Sequence No

Read Input Digital Filter Sequence No

Read Alarm Hysteresis Sequence No

Read Input Shift Limits Sequence No

Read Level 0 Parameters Sequence No

Read Level 1 Parameters 1 Sequence No

Read Level 1 Parameters 2 Sequence No

166

Read Level 2 Parameters 1 Sequence No

Read Level 2 Parameters 2 Sequence No

169

General-purpose Read Sequence No

Appendix D

E5jK Digital Controller Write Protocol

Write Alarm Value Sequence No

Write Set Point Sequence No

Write Dead Band Sequence No

Write Manual Reset Value Sequence No

Write Cooling Coefficient Sequence No

Write Hysteresis Sequence No

Write SP Ramp Time Unit and Set Value Sequence No

Write Control Period Sequence No

Appendix D

Write LBA Detection Time Sequence No

Write MV at Stop Time and at PV Error Sequence No

Write MV Limits Sequence No

Write Input Digital Filter Sequence No

Write Alarm Hysteresis Sequence No

Write Input Shift Value Sequence No

Write Level 0 Parameters Sequence No

Write Level 1 Parameters 1 Sequence No

Write Level 1 Parameter 2 Sequence No

Write Level 2 Parameters 1 Sequence No

Write Level 2 Parameters 2 Sequence No

Switch to Level 0 Software Reset Sequence No

General-purpose Write Sequence No

Run/Stop Sequence No

Remote/Local Sequence No

Execute/Cancel AT Sequence No

Switch to Level 1 Sequence No

Software Reset Sequence No

E5ZE Temperature Controller Read Protocol

Appendix E

Signal name Signal direction Pin No Brevi Ation

RS-232C Connections

Pin No Signal name Abbreviation Signal direction

RS422/485 Connections RS-485

Appendix E

RS-422A

Unit Number Switch

Switch Settings

Communications Parameter DIP Switch

Baud Rate DIP Switch

192

Read Output Values Sequence No

Read Set Point, Process Value, and Output Value Sequence No

195

196

Read Output Mode Sequence No

Read Alarm Mode Sequence No

Read Alarm Temperatures Sequence No

Read Operation Status Sequence No

Read Error Status Sequence No

Read Setting Unit Sequence No

Read Input Shift Value Sequence No

Read Ramp Value Sequence No

Read Present Set Point Sequence No

Read Output Value Limit Sequence No

Read Output Value Change Rate Limit Sequence No

Read HB Alarm and HS Alarm Valid Channels Sequence No

Read Heater Current and SSR Leakage Current Sequence No.121

Read Dead Band/Overlap Band Sequence No

208

E5ZE Temperature Controller Write Protocol

Appendix F

Write Set Point Setting Unit 1 Sequence No

Write Set Point Setting Unit 0.1 Sequence No

212

213

Write Output Mode Sequence No

Write Alarm Mode Sequence No

Write Alarm Temperature Setting Unit 1 Sequence No

Write Alarm Temperature Setting Unit 0.1 Sequence No

Start Autotuning Sequence No

Cancel Autotuning Sequence No

Write Setting Unit Sequence No

Appendix F

Write Ramp Value Sequence No

Write Manual Output Value Sequence No

Write Output Value Limit Sequence No

Write Output Value Change Rate Limit Sequence No

Save Settings Sequence No

Initialize Settings Sequence No

Write HB and HS Alarm Valid Channels Sequence No

Write Dead Band/Overlap Band Sequence No

Start Control Sequence No

Stop Operation or Control Sequence No

Start Manual Operation Sequence No

E5jJ Temperature Controller Protocol

Appendix G

Signal name Abbreviation Signal direction Pin No

RS422A/485 Connections

Input Signal ground

Appendix G

Select Backup Mode Sequence No

Select Remote Mode Sequence No

Select Local Mode Sequence No

Select RAM Write Mode Sequence No

Save Set Point Sequence No

Write Parameters 1 Sequence No

Write Parameters 2 Sequence No

235

Read Parameters 1 Sequence No

Read Parameters 2 Sequence No

238

Read Output Value Sequence No

Read Set Point Limit Sequence No

Read Heater Current Sequence No

Read Initial Status Sequence No

241

242

Appendix H

ES100j Digital Controller Protocol

Appendix H

Appendix H

RS-422A/485 Connections

Read Event Data Sequence No

Read Time Signal Sequence No

Read Error Detection Data Sequence No

249

Read Heater Burnout Data Sequence No

Read PV Data Sequence No

Read SP Data Sequence No

Read MV Data Sequence No

Read Control Monitor Data Sequence No

255

Read Adjustment Parameters Sequence No

257

258

Write Adjustment Parameters Sequence No

Read PID Control Parameters 1 Sequence No

261

Read PID Control Parameters 2 Sequence No

263

Write PID Control Parameters 1 Sequence No

265

Write PID Control Parameters 2 Sequence No

Read Local SP Sequence No

268

Write Local SP Sequence No

Read Program Parameters Sequence No

271

Write Program Parameters Sequence No

Remote Setting Mode Sequence No

Local Setting Mode Sequence No

External Setting Mode Sequence No

Run Command Sequence No

Reset Stop Sequence No

Auto Mode Sequence No

Manual Mode Sequence No

Execute A.T. Sequence No

Cancel A.T. Sequence No

Change Pattern No. Sequence No

Change Bank No. Sequence No

Read Controller Status Sequence No

General-purpose Command Sequence No

282

K3Tj Intelligent Signal Processor Protocol

Protocol Configuration

Sequence Communications Function Ladder interface

Ladder Interface Settings

Appendix

Send word Receive word Allocation

Signal name Abbreviation Pin No Direction

K3T j Intelligent Signal Processor Protocol

Signal name Abbreviation Signal direction Terminal

Inverting output Input or output Non-inverting output

Reset by Unit Number Sequence No

Reset Control Continuous Units Sequence No

289

Write Set Value LL Continuous Units Sequence No

Write Set Value H Continuous Units Sequence No

Write Set Value L Continuous Units Sequence No

Write Set Value with Bank by Unit Number Sequence No

Write Set Value HH with Bank Continuous Units Sequence No

Write Set Value LL with Bank Continuous Units Sequence No

Write Set Value H with Bank Continuous Units Sequence No

Write Set Value L with Bank Continuous Units Sequence No

Write Set Value O5 with Bank Continuous Units Sequence No

Write Set Value O1 with Bank Continuous Units Sequence No

Write Set Value O2 with Bank Continuous Units Sequence No

Read Set Value by Unit Number Sequence No

Read Set Value L Continuous Units Sequence No

Read Set Value HH Continuous Units Sequence No

Read Set Value H Continuous Units Sequence No

Read Set Value LL Continuous Units Sequence No

Read Set Value with Bank by Unit Number Sequence No

Read Set Value L with Bank Continuous Units Sequence No

Read Set Value HH with Bank Continuous Units Sequence No

Read Set Value H with Bank Continuous Units Sequence No

Read Set Value LL with Bank Continuous Units Sequence No

Read Set Value O1 with Bank Continuous Units Sequence No

Read Set Value O3 with Bank Continuous Units Sequence No

Read Set Value O2 with Bank Continuous Units Sequence No

Read Holding Data Sequence No

Read Holding Data PH Continuous Units Sequence No

Read Holding Data BH Continuous Units Sequence No

Offset Contents Data

Read Display Value PV by Unit Number Sequence No

300

Read Display Value PV Continuous Units Sequence No

Model Data Read by Unit Number Sequence No

Model Data Read Continuous Units Sequence No

303

Appendix J

V500/V520 Bar Code Reader Protocol

Appendix J

V500 Connections

V520 Connections

Host Interface

System Setting

V500-C11 BCR Functions

V520-R121

Data Read Sequence No

BCR Read Start Sequence No

BCR Read Stop Sequence No

Complete Data Read Sequence No

BCR Function Write V500 Sequence No

CODE93

BCR Function Read V500 Sequence No

Log Data Output Request V500 Sequence No

Preset Data Set V500 Sequence No

BCR Connection Confirmation V500 Sequence No

Data Continuous Read Interrupt V500 Sequence No

Log Data Clear V500 Sequence No

Data Continuous Read Scan V500 Sequence No

BCR Initialize V500 Sequence No

General-purpose Command 2 Sequence No

General-purpose Command 1 Sequence No

Data Continuous Read Interrupt V520 Sequence No

Appendix J

Receive Data Storage Word Allocation 3rd Operand of Pmcr

Appendix K

3Z4L Laser Micrometer Protocol

Appendix K

319

3Z4L-4000 Series DIP Switch

DIP Switch Settings

3Z4L-3000 Series DIP Switch

Setting Status

Delimiter Control Code Setting 3Z4L-4000 Series

3Z4L-3000 Series

322

3Z4L Clear Sequence No

Memory Switch Set Sequence No

Offset Contents Data Data format Series

Mm Unit Set Sequence No

Calibration Set Sequence No

Calibration Release Sequence No

Program Number Set 3000-series Sequence No

Measurement Condition Set 3000-series Sequence No

326

327

Measurement Condition Release 3000-series Sequence No

Measurement Condition List Request 3000-series Sequence No

329

330

Zero Run Measurement Start 3000-series Sequence No

Single Run Measurement Start 3000-series Sequence No

Continuous Measurement Start Scan 3000-series Sequence No

Data Request 3000-series Sequence No

Measurement Termination 3000-series Sequence No

Statistic Processing Execution 3000-series Sequence No

Statistic Processing Memory Clear 3000-series Sequence No

Statistic Processing Non-execution 3000-series Sequence No

All Statistic Memory Clear 3000-series Sequence No

Statistic Result Request 3000-series Sequence No

Offset Contents Data Data format

Appendix K

Memory Switch Set 1 3000-series, High-speed Type Sequence No

Memory Switch Set 2 3000-series, High-speed Type Sequence No

337

338

3Z4L Initialize 3000-series Sequence No

Measurement Condition Set 4000-series Sequence No

341

Measurement Condition Release 4000-series Sequence No

Measurement Condition List Request 4000-series Sequence No

Single Run Measurement Start 4000-series Sequence No

Deflection Measurement Start 4000-series Sequence No

Continuous Measurement Start Scan 4000-series Sequence No

Forced Positive Zero 4000-series Sequence No

Continuous Measurement Termination 4000-series Sequence No

Data Request 4000-series Sequence No

Forced Negative Zero 4000-series Sequence No

General-purpose Command 1 4000-series Sequence No

General-purpose Command 2 4000-series Sequence No

Appendix L

Visual Inspection System Protocol

Appendix L

Pin No Signal name Abbreviation

For RS/CS Flow Control

Measurement Execution F200 Sequence No

Offset Content data format Data

Continuous Measurement Execution Scan F200 Sequence No

Continuous Measurement Execution Interrupt F200 Sequence No

Reference Object Registration Criterion F200 Sequence No

Reference Object Registration Group F200 Sequence No

Evaluation Condition Change F200 Sequence No

Arbitrary Measurement Value Acquisition F200 Sequence No

Measurement Execution F300 Sequence No

Continuous Measurement Execution Scan F300 Sequence No

358

Continuous Measurement Execution Interrupt F300 Sequence No

360

Illumination Fluctuation Follow Execution F300 Sequence No

Measurement Execution and Positioning F350 Sequence No

Scene Switching and Positioning F350 Sequence No

Camera Designation and Positioning F350 Sequence No

Camera Change Decrease by 1 F200/300 Sequence No

Scene Switching Increase by 1 Sequence No

Reset F200/300 Sequence No

Scene Switching Decrease by 1 Sequence No

Camera Change Increase by 1 F200/300 Sequence No

General-purpose Command Send/Receive Sequence No

Scene Switching Arbitrary Sequence No

General-purpose Command Send Sequence No

Measurement, Inspection Termination Sequence No

366

Appendix M

V600/V620 ID Controller Protocol

Appendix M

369

RS-422A Connections

V600/620-CD1D DIP Switches

DIP Switch

372

V600-CAjA DIP Switches

Read ASCII/1 Sequence No

Read ASCII/2 Sequence No

Read ASCII/4 Sequence No

Read ASCII/8 Sequence No

Read Hexadecimal/1 Sequence No

Read Hexadecimal/2 Sequence No

Read Hexadecimal/4 Sequence No

Read Hexadecimal/8 Sequence No

Auto-read ASCII/1 Sequence No

Auto-read Hexadecimal/1 Sequence No

Polling Auto-read Ascii Sequence No

Polling Auto-read Sub-command ASCII/4 Sequence No

Polling Auto-read Sub-command ASCII/2 Sequence No

Polling Auto-read Sub-command ASCII/8 Sequence No

Polling Auto-read Sub-command Hexadecimal/2 Sequence No

Polling Auto-read Hexadecimal Sequence No

Polling Auto-read Sub-command Hexadecimal/8 Sequence No.517

Polling Auto-read Sub-command Hexadecimal/4 Sequence No

Write ASCII/1 Sequence No.518

Write ASCII/2 Sequence No

388

Write ASCII/4 Sequence No

Write ASCII/8 Sequence No

Write Hexadecimal/1 Sequence No

Write Hexadecimal/2 Sequence No

Write Hexadecimal/4 Sequence No

Write Hexadecimal/8 Sequence No

Auto-write Hexadecimal/1 Sequence No

Auto-write ASCII/1 Sequence No

Polling Auto-write ASCII/2 Sequence No

Polling Auto-write Subcommand ASCII/8 Sequence No

Polling Auto-write Subcommand ASCII/2 Sequence No

Polling Auto-write Subcommand ASCII/4 Sequence No

Polling Auto-write ASCII/4 Sequence No

Polling Auto-write Hexadecimal/2 Sequence No

Polling Auto-write Subcommand Hexadecimal/2 Sequence No

Polling Auto-write Subcommand Hexadecimal/4 Sequence No

Polling Auto-write Hexadecimal/4 Sequence No

Polling Auto-write Hexadecimal/8 Sequence No

Polling Auto-write Subcommand Hexadecimal/8 Sequence No

Data Check Sequence No

Control Sequence No

Error Information Read Sequence No

Command Processing Cancel Sequence No

Polling Auto-read Command Processing Cancel Sequence No

Polling Auto-write Command Processing Cancel Sequence No

402

Hayes Modem AT Command Protocol

Appendix N

Compatible Modems

Modem Settings

Operand and Word Settings of Pmcr

Dialling

Password Verification

Setting Example

Data Send/Receive

Password Verification Operation

Operand

Hang Up Command

Escape Mode

Communication Errors

Numbers

Index

413

414

415

416

417

Revision History

Revision code Date Revised content

Original production

Authorized Distributor