1152700 • Issue 1 • February 2001 • Section 2 Operations and Maintenance

Page 2 of 10

3.Route the fiber cables to the Cellworx STN rack and to either upper side of the fiber management tray. For management purposes, it is recommended that the receive fibers are routed across one direction and the transmit fibers across the other direction. Refer to the example shown in Figure

4.Using the fiber routing flanges, dress the fibers to the respective card slots per work order. Keep in mind the direction of traffic flow for the fibers. The slots designated for RIC interfaces or 155 CRS expansion shelf interfaces are slots 16 and 17. Slot 16 TX port will connect to the next node slot 16 RX port, continuing around the ring until all slot 16 cards are connected. Slot 17 TX port will connect to the next node slot 17 RX port until all slot

17 cards are fibered together around the ring. Refer to Figure

5.Leave enough slack in the fibers to enable them to dangle about six inches down the front of the shelf as shown in Figure

6.Route the remaining fibers to the respective 155 CRS equipped slots per work order. Keep in mind the slot numbers, matching them with the tagged fibers.

7.Dress the fiber cables in along the rack using panduct or similar routing devices per customer applications.

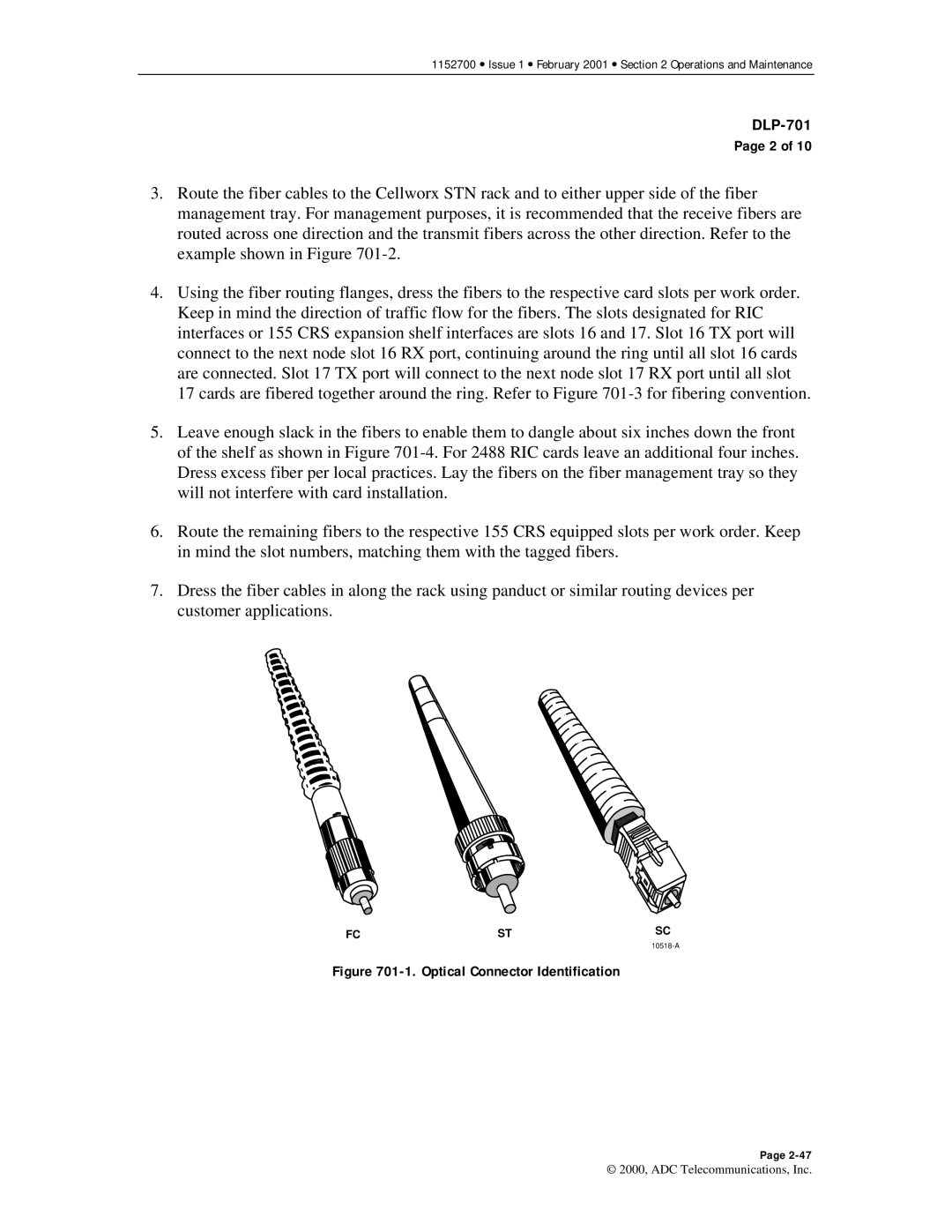

FC | ST | SC |

|

|

Figure 701-1. Optical Connector Identification

Page

© 2000, ADC Telecommunications, Inc.